The following information is provided by Sarig Nachum of the Cambridge University Engineering Department.

The chemical composition of the steel is Fe-0.2C-13.7Cr-0.4Mn-0.2Si wt%. This is in the category of AISI 420 martensitic stainless steel, but the structures reported here are unusual because of the methods used to make three-dimensional objects.

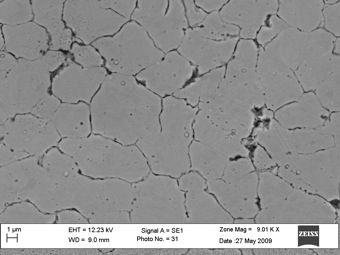

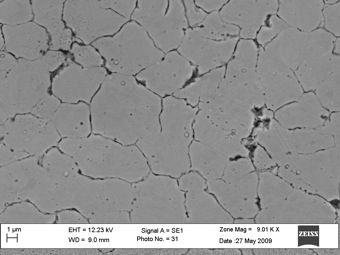

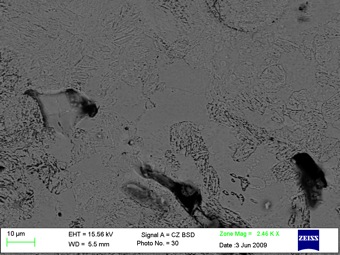

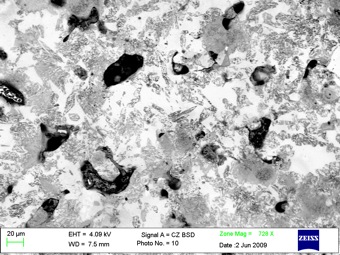

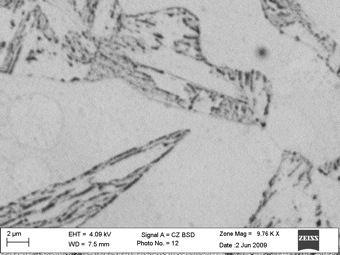

The powders are consolidated in a graphite die under a nitrogen atmosphere by heating to 960°C for 7 minutes at a pressure of 60 MPa. This brings them into the phase field where austenite and M23C6 are the stable phases. Hence the decoration of the prior austenite grain boundaries with M23C6, where the `M' stands for metal atoms such as Fe, Cr.

|

|

|

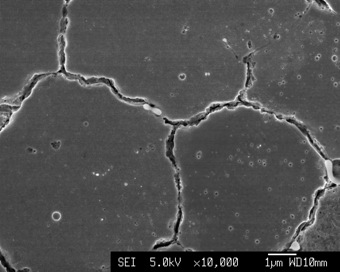

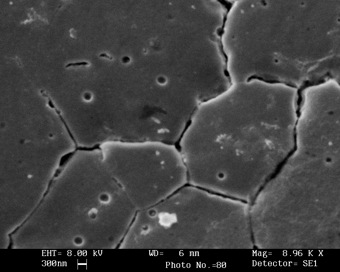

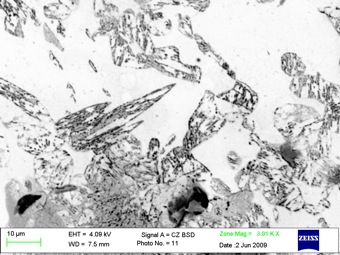

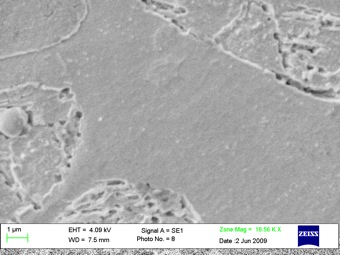

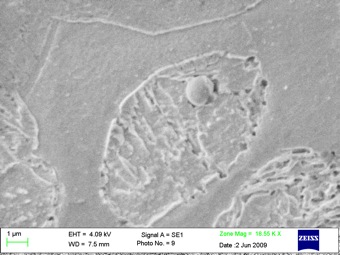

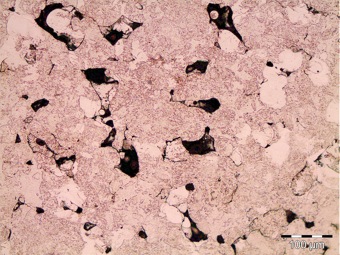

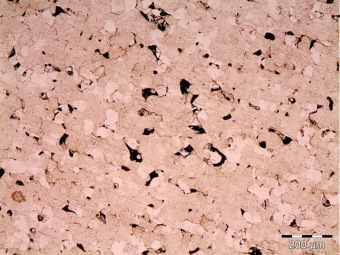

This is a process in which powders, 20-50 μm in size are sprayed on to a substrate, and melted using a 21 W power laser with a `beam diameter' of 50 μm. The laser scans at 2 mm s-1 and the powder is fed at 2.7×10-4 g s-1. In this way, cylinders of diameter 3 mm and length 3 mm are created. The micrographs illustrated below are taken from the top deposit, unaffected by the deposition of subsequent layers.

The microstructure contains a significant amount of δ-ferrite because of the very high temperatures reached, with residual phases following the decomposition of austenite which grows from the δ-ferrite during cooling.

|

|

|

|

|

|

|  |

|

|

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Mechanicallly Alloyed | Theses | Retained Austenite |

| PT Group Home | Materials Algorithms |