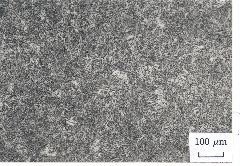

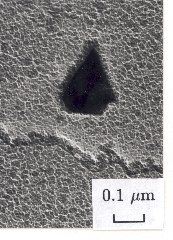

1

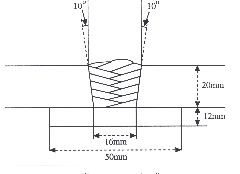

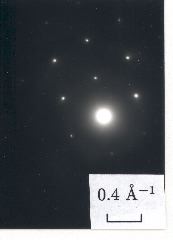

2

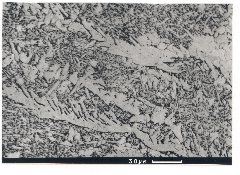

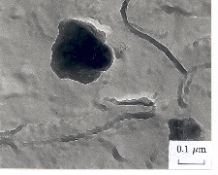

3

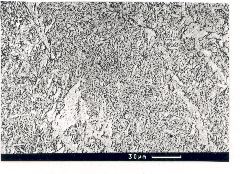

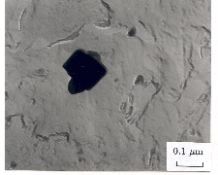

4

5

6

7

8

9

10

11

12

13

14

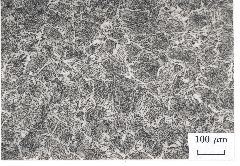

15a

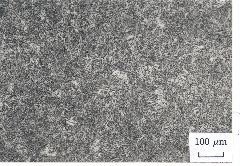

15b

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

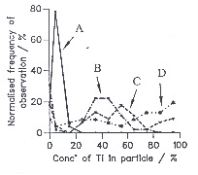

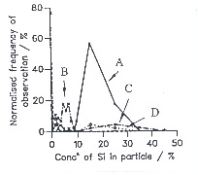

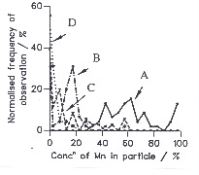

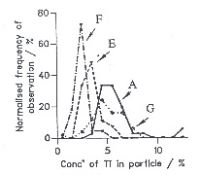

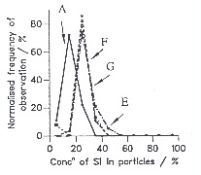

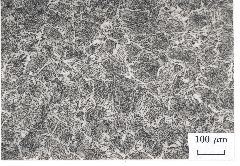

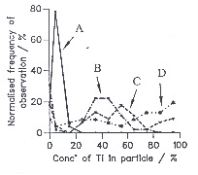

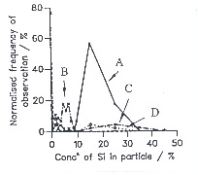

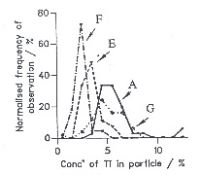

Two series of experimental submerged are welds have been produced, in which additions of titanium-rich and tungsten-rich powders have been made to the flux. Such additions have caused variations in weld composition. Weld microstructures were observed to become more intragranularly dominated with increases in either titanium or tungsten. In titanium welds, microstructural changes were due to changes in inclusion mineralogy and consequently to nucleating potential, as well as to matrix hardenability. In tungsten welds, microstructural variations were solely due to the effects of tungsten in solution.

Materials Science and Engineering A, Vol. 223, 1997, pp. 146-157.

Download PDF file of paper (18 Mb)

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15a |

15b |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

32 |

33 |

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Mechanicallly Alloyed | Theses | Retained Austenite |

| PT Group Home | Materials Algorithms |