![]() [1]

[1]

DEFORMATION AND RECRYSTALLISATION OF A YTTRIA DISPERSION-STRENGTHENED, MECHANICALLY ALLOYED IRON (MA957)

C. Capdevila and H. K. D. H. Bhadeshia

Department of Materials Science and Metallurgy,

University of Cambridge, Pembroke street, Cambridge CB2 3QZ, United Kingdom, www.phase-trans.msm.cam.ac.uk

ABSTRACT

Mechanically alloyed and compacted dispersion-strengthened iron base materials show a strange behaviour, that the recrystallisation temperature drops when the compacted sample is cold-deformed. Controlled experiments have been conducted on MA957, which is a yttria oxide dispersion strengthened iron alloy. This involved the study of grain structure evolution in samples which were systematically bent and then heat treated. A bend test introduces a strain gradient and different senses of deformation (relative to the extrusion direction) about the neutral axis. It has therefore been possible to characterise the recrystallisation behaviour in both tension and compression in a single test, with varying levels of strain. The results imply anything that introduces heterogeneity into the microstructure stimulates recrystallisation.

1. INTRODUCTION

The ferritic oxide dispersion-strengthened alloy MA957 discussed in this paper is obtained using mechanical alloying (Matucha and Ruhle.1993; Elliot and Hack 1990). This introduces a uniform distribution of fine oxide particles, which provide the resistance to creep deformation at elevated temperatures. As the ferritic state makes the alloy resistant to radiation induced swelling, MA957 was intended for the manufacture of tubes for nuclear reactor applications, to contain liquid sodium at about 700 ºC (Coheur et al.1986; Evans et al.1992).

The mechanical alloying process involves the intense deformation of mixtures of elemental or master alloy powders, which are then canned and extruded for consolidation. The extruded material has a sub-micron grain structure and is hard. The alloy is, therefore, given a recrystallisation heat treatment, which leaves it with a very coarse, columnar grain structure, appropriate for applications where creep deformation must be minimised.

The alloy, after consolidation from the powder, has a high stored energy, due to deformation and the small grain size. The energy is typically 1 J g-1, which is much greater than in conventionally deformed metals (Chou and Bhadeshia 1995). It is therefore peculiar that the consolidated alloy has to be heated to temperatures as high as 1400 ºC before recrystallisation begins (Bhadeshia 1997). An important observation by Regle and Alamo (1993) is that the recrystallisation temperature dramatically decreases if the consolidated material is cold-deformed prior to annealing.

It appears that the uniformity and the fine scale of the microstructure in the consolidated alloy makes the nucleation of recrystallisation difficult because the grain boundary junctions are strong pinning points, restricting the bowing of grain boundaries (Bhadeshia, 1997). In effect, the fine grains cannot be considered topologically independent, as is assumed in recrystallisation models. In these circumstances, anything that introduces inhomogeneity into the microstructure will ameliorate the recrystallisation process, explaining the Regle and Alamo results.

In the present work, we examine the effect of deforming the compacted material on the development of the recrystallisation grain structure using bend samples, where there is not only a deformation gradient about the neutral axis but also a change in the sign of the plastic strain.

2. EXPERIMENTAL PROCEDURE

INCO Alloys (Hereford, United Kingdom) supplied the material (Table I) in the unrecrystallised state. It was fabricated by charging three primary powders (elemental iron, pre-alloyed metallic alloys, and yttria) into a water-cooled vertical attritor for mechanical alloying. The consolidation of the resultant powder was achieved by extrusion at 1000 ºC, while packed in a mild steel can. This was followed by rolling at 1000 ºC, to reduce the diameter from 54 to 25 mm. The extrusion and rolling are not to be thought of as "hot working" processes, since the final microstructure is in a cold deformed state (grain size 0.4 mm).

Table 1. Chemical composition (wt. %).

|

C |

Cr |

Ti |

Mo |

Y2O3 |

|

0.01 |

14.0 |

1.0 |

0.3 |

0.27 |

The bend test samples were 100 mm length, machined parallel to the extrusion direction, and square in cross-section (7 ´ 7 mm). Bending was carried out using a MAYES - 100 kN. Samples were etched for optical microscopy using 2 g CuCl2, 40 ml HCl, and 40-80 ml ethanol.

3. RESULTS AND DISCUSSION

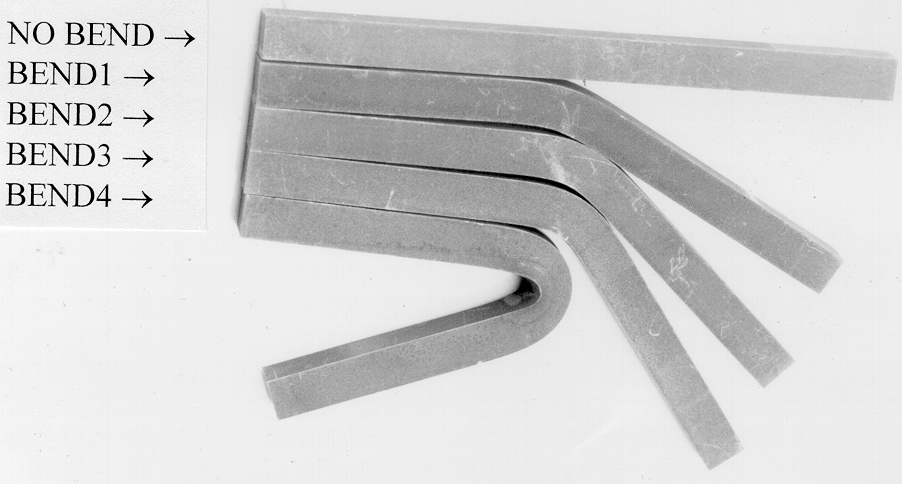

Figure 1 shows the form of the bend test samples and Table 2 summarises the experimental parameters. The thickness of the layer of yielded material increases with the bending moment M, so that the elastic-plastic boundary approaches the neutral plane as M becomes larger. The moment MP required to make the section fully plastic is given by (Johnson and Mellor, 1973):

![]() [1]

[1]

where w and h are the width and height respectively of the square section of the sample. The yield stress s y =1125 MPa was calculated according Badmos et al.(1998).

Fig. 1. Bend test samples with different levels of deformation

The thickness of the layer of yielded material increases with the bending moment M, so that the elastic-plastic boundary approaches the neutral plane as M becomes larger. The moment MP required to make the section fully plastic is given by (Johnson and Mellor, 1973):

![]() [1]

[1]

where w and h are the width and height respectively of the square section of the sample. The yield stress s y =1125 MPa was calculated according Badmos et al.(1998).

Table 2. Bend test parameters.

|

Displacement / mm |

Maximum Load / kN |

Bend Angle / radians |

|

|

Bend1 |

9.23 |

6.2 |

p /1.2 |

|

Bend2 |

15.57 |

6.07 |

p /1.3 |

|

Bend3 |

16.81 |

6.9 |

2p /3 |

|

Bend4 |

41.12 |

10.1 |

p /6 |

For the dimensions of the samples used in this work MP = 96 N m. From the bend tests discussed below the calculated values for bending moment are listed in Table 3. For sample 4, M is higher than MP, so a fully plastic sample is expected. However, Johnson and Mellor (1973) have shown that a residual layer of elastic material remains at the neutral surface, associated with a large gradient of stress.

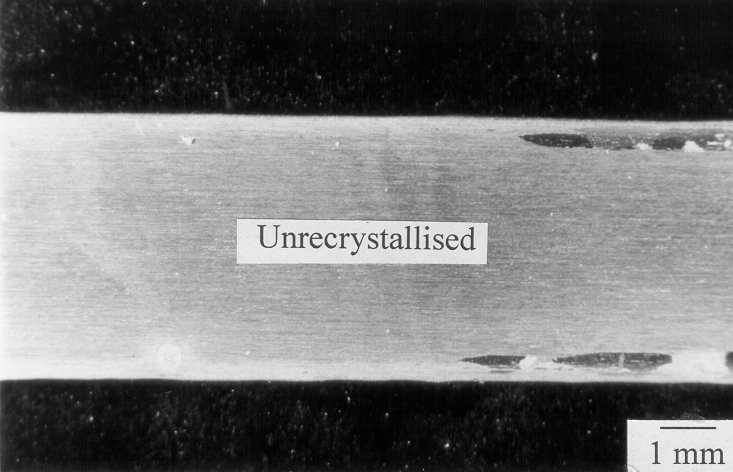

Recrystallisation in iron-base ODS alloys occurs at exceptionally high temperatures, of the order of 0.9 of the melting temperature (in MA957 Tm=1478 ºC). As shown in Fig.2, the minimum temperature at which the material recrystallises after 1 h of heat treatment has been measured for MA957 to be TR =1330 ºC.

Fig. 2. Longitudinal section of sample recrystallised at 1330 ºC without bending.

Table 3. Values for M obtained from bending tests.

|

Bending Moment / N m |

|

|

Bend1 |

71 |

|

Bend2 |

70 |

|

Bend3 |

80 |

|

|

115 |

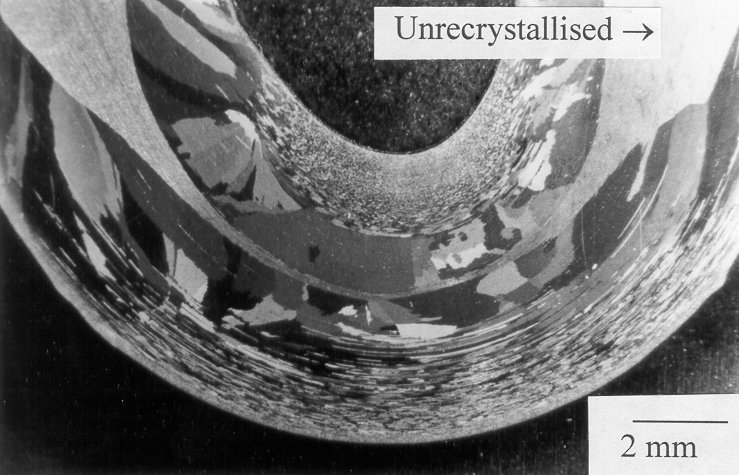

Fig. 3. Longitudinal section of sample 2, recrystallised at (TR- 30 ºC) for 1 h

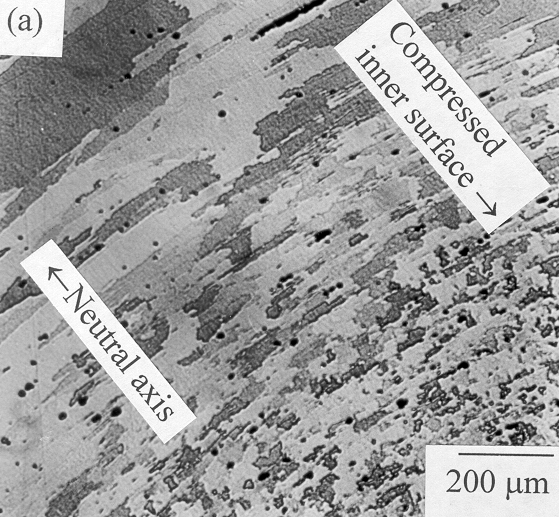

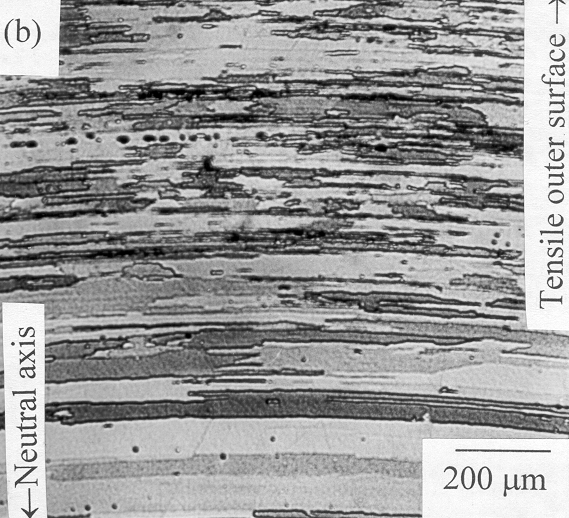

In order to characterise the effect of deformation on the recrystallisation temperature, heat treatments were carried out on the bent samples at temperatures lower than TR. . Figures 3 and 4 show the microstructures of samples 2 and 4 after deformation and recrystallisation at (TR- 30 ºC) for 1 h. The samples have almost fully recrystallised even though T<TR. Consistent with the work of Regle and Alamo, deformation clearly decreases the minimum temperature at which recrystallisation begins. The grain structures in the tensile and compressed areas of sample 4 are presented in Fig.5. As a greater strain has the effect of refining the recrystallised grain structure, which also becomes more isotropic, the grains in the tensile outer regions (Fig.5a) are more equiaxed and refined than those in the compressed part of the sample (Fig.5b).

Fig. 4. Longitudinal section of sample 4, recrystallised at (TR- 30 ºC) for 1 h

Fig. 5. Longitudinal section of sample 4, recrystallised at (TR- 30 ºC) for 1 h. Detailed view of (a) compressed region, and (b) tensile region.

4. SUMMARY

The effect of cold deformation on the recrystallisation of MA957 samples is two fold. Firstly, the recrystallisation temperature decreases, consistent with the hypothesis that anything that makes the original microstructure heterogeneous will encourage recrystallisation. This is because the microstructure prior to recrystallisation is uniform with grains that are so fine their junctions are powerful pinning points. The second effect is that the increase in the number and density of recrystallisation nuclei, due to (non uniform) cold deformation, leads to fine grain structures, which are also more isotropic in three dimensions.

If coarse, columnar grain structures are desirable in the context of creep strength, then the present work indicates that the processing of MA957, or similar materials in order to produce tubes, should avoid plastic strain gradients. Indeed, it is predicted that coarse, directional grain structures are only expected when the deformation following consolidation is either zero or very large, since both cases lead to a uniform distribution of plastic strain.

ACKNOWLEDGEMENT

The authors are grateful to Professor A. H. Windle for the provision of laboratory facilities at the University of Cambridge, to INCO Alloys for MA957 and the European Commission for funding the work via a BRITE-EURAM III project. It is a pleasure to acknowledge our project partners: Plansee GmbH, Metall-Spezialrohr GmbH (MSR), Sydkraft, Risø, Mitsui Babcock Technology Centre and Liverpool University.

REFERENCES

Asano, K., Kohno, Y., Kohyama, A., Suzuki, T. ,and Kusanagi, (1988). Microstructural evolution of an oxide dispersion strengthened steel under charged-particle irradiation. J. Nuclear Mater. 155, 928-934

Badmos, A. Y. , Bhadeshia, H. K. D. H., and Mackay, D. J. C. (1998). Tensile properties of mechanically alloyed oxide dispersion strengthened iron alloys. Part 1 - Neural Network model. Materials Science and Technology. 14, 793-809.

Bhadeshia, H. K. D. H. (1997). Recrystallisation of practical mechanically alloyed iron-base and nickel base superalloys. Materials Science and Engineering A (1997) 223, 64-77.

Coheur, L., Geladi-Heylen, M., and Delavignette, O. (1986). Development of ODS alloys for high temperature service. In: High Temperature Alloys for Gas Turbines and Other Applications 1986. Eds. J. Bertz et al. (Universite de Liege and European Commission, Liege) 1011-1022

Chou, T. S. and Bhadeshia, H. K. D. H. (1993a), Grain control in mechanically alloyed oxide dispersion strengthened MA957 steel, Materials Science and Technology. 9, 890-897.

Chou, T. S., and Bhadeshia, H. K. D. H. (1993b).Crystallographic texture in mechanically alloyed oxide dispersion strengthened and MA957 steels. Metallurgical Transactions A. 24A, 773-779.

Chou, T. S., and Bhadeshia, H. K. D. H. (1995). Dynamic recrystallisation in hot deformed oxide dispersion strengthened MA956 and MA957 steels. Materials Science and Technology. 11, 1129-1138.

Elliot, C., and Hack, G. A. J. (1990). The evolution of microstructure and particle morphology during mechanical alloying of ductil metals. In: Structural Applications of Mechanical Alloying. Eds: Froes and deBardadillo (ASM Society, USA) 15-19.

Evans, P. J., Martin, J. W., and Little, E. A. (1992). Secondary recrystallisation of MA957 oxide dispersion strengthened ferritic superalloy. Materials Science and Technology. 8, 531-536.

Hack, G. A. (1984). Developments in the production of oxide dispersion strengthened superalloys. Powder Metall. 27, 73-79.

Johnson, W., and Mellor, P. B. (1978). Engineering Plasticity. (Vans Nostrand Reinhold, London), p. 125.

Matucha, K. H., and Ruhle M. (1992). Alloy formation and amorphization by mechanical alloying of a nickel-alloy with Y2O3 dispersion. Metall 46, 1238-1242.

Miodownik, M. A., Martin, J. W., and Little, E. A. (1994). Secondary recrystallisation of two oxide dispersion strengthened ferritic superalloys: MA956 and MA957. Materials Science and Technology. 10, 102-109

Regle, H. and Alamo, A. (1993). Secondary recrystallisation of ODS ferritic alloys. J. Phys. IV 3, C7, 727-730.