Professor Kouichi Maruyama, Professor Purmensky and Dr Igarashi

Tokyo at night.

Tokyo

Taj Indian restaurant.

The team, courtesy of Professor Matsuo, Tokyo Institute of Technology.

Hotel Miyako, Tokyo.

The subway train.

Tokyo Institute of Technology

Japan Society for the Promotion of Science, 123 committee on heat-resistant steels.

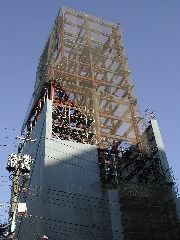

Beautiful steel-infrastructure for a multi-storey building under construction in Tokyo.

My computer.

Dinner with Nobuhiro Fujita and Manabu Takahashi, Nippon Steel Corporation.

Bullet train, Tokyo Station.

Train cleaners, ready for next arrival.

Steel Pentograph support.

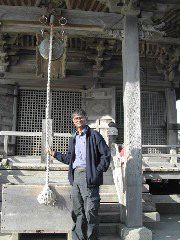

Visit to Matsushima, Sendai, courtesy of Kouichi Maruyama.

Traditional Japanese tea ceremony.

Japanese maple leaf.

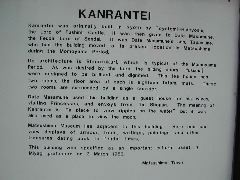

The first two symbols stand for Metallurgy. The sign means the Department of Metallurgy. At Tohoku University. The oldest metallurgy in Japan.

Department of Materials Science, Tohoku University.

Department of Materials Processing, Tohoku University.

Sueng Hwan Park and Professor Hiroyuki Kokawa, Tohoku University. Sueng presented a lecture on friction stir welding of steel, to be followed by a demonstration.

Friction-stir welding machine.

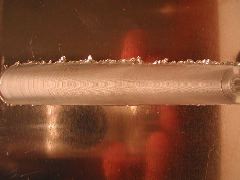

The tip of the steel tool.

Friction stir-weld, butt joint between aluminium plates.

Friction stir-weld, butt joint between aluminium plates.

The hole at the end is where the operation terminated. Made at Tohoku University.

Japanese tea ice-cream.

Tourist attraction, about 160 m high, in Sendai

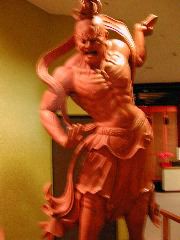

Inside the giant statue.

Inside the giant statue.

The sight of Sendai from inside the giant statue.

Inside the statue.

Professor Tadao Watanabe, Tohoku University.

.... with Koichi Kawahara

Device to produce a magnetic field of about 1.6 Tesla

Device to produce a magnetic field of about 1.6 Tesla

Device with supeconducting magnets to produce a field of about 6 Tesla

Corrosion experiments.

Sendai Airport, designed with steel.

Sendai Airport, designed with steel.

Sendai Airport, designed with steel. Inside the terminal.

Sendai Airport, designed with steel. Inside the terminal.

Sendai Airport, designed with steel. Inside the terminal.

Sendai Airport, designed with steel. Inside the terminal.

Flight from Sendai to Nagoya.

All Nippon Airlines.

Daido Steel, Nagoya.

Daido Steel, Nagoya.

Lecture on Hard Bainite.

Hydrogen fuel cell.

Fuel cell and hydrogen storage device based on Ti/Zr Laves phase. Occupies a tenth of the volume of the gas phase.

Toy car fitted with hydrogen fuel cell and storage device.

Toy car fitted with hydrogen fuel cell and storage device.

Turbo-charger. The melting temperature is about 1500°C, service temperature about 900°C.

Noda Toshiharu (General Manager), Harry, Shigeki Ueta and Toshiharu Shimizu, at Daido Steel, Research & Develpment.

Nagoya Airport

Nagoya Airport

Nagoya Airport

Flight from Nagoya, landed in Narita Tokyo.

Flight from Nagoya, landed in Narita Tokyo.