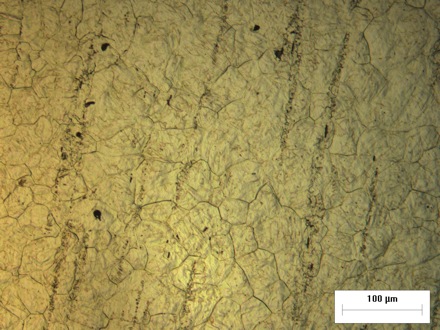

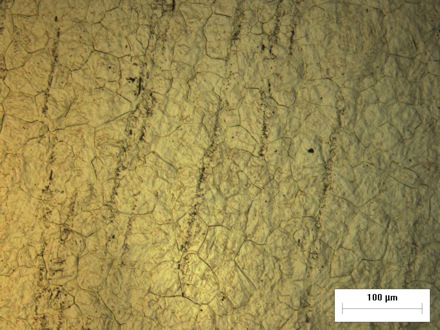

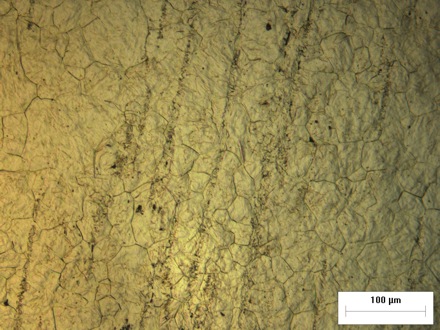

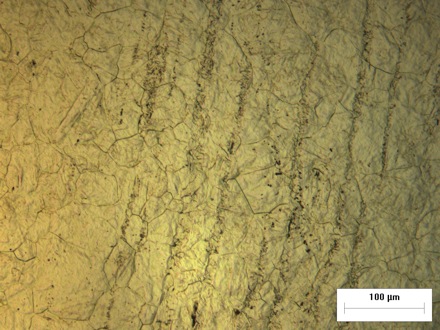

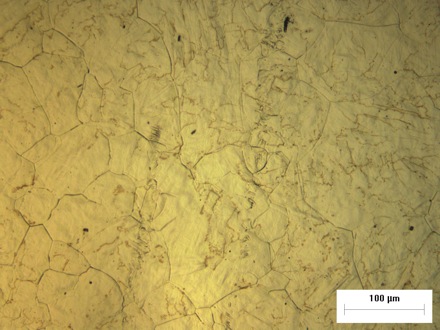

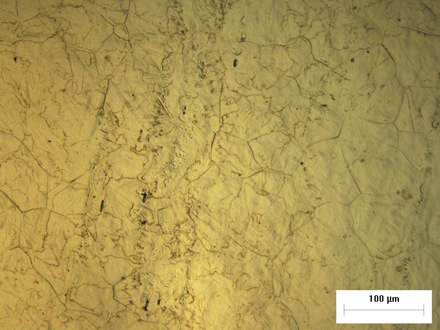

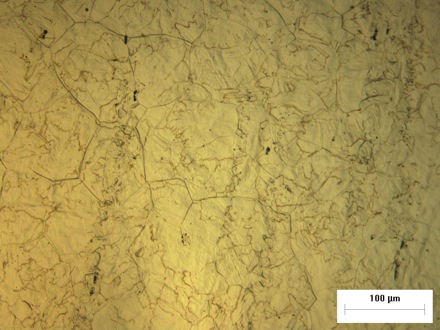

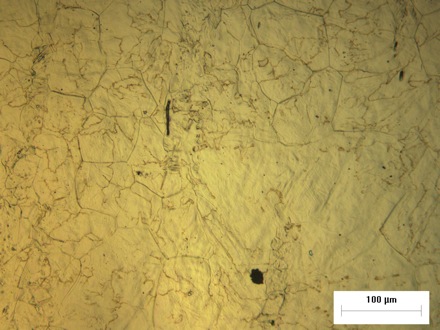

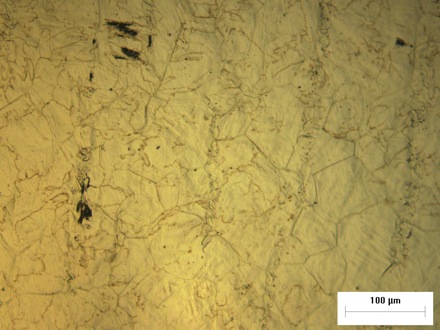

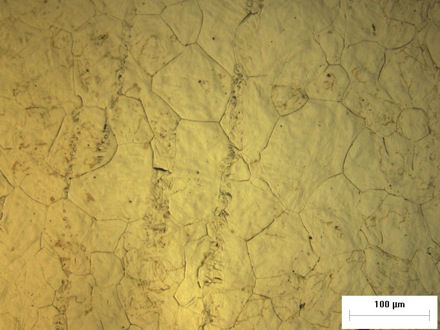

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched

Fe-0.4C-4Ni-2Si wt%, austenitised at 800 C for 30 min and then quenched