Current project

TECHNOLOGICAL FORESIGHT CHALLENGE PROJECT

Designing Materials for our Wealth :

From Aerospace to Power Plant :

A Revolutionary Computer Modelling Approach.

The problem

Modelling

Testing the models

Examples

Design of new alloys

Processing

First results

Future work

The problem

The aim of this project is to design several new alloys -steels and nickel superalloys- that could be used to fabricate steam boilers and steam turbines for the next generation of power plants, with steam temperatures as high as 750oC (to increase efficiency and reduce pollution).

The basic required property is a creep rupture stress of 100MPa at 650oC (for steels) or 750oC (for nickel alloys) over 100000 h. However, other properties, such as yield stress, Y, ultimate tensile stress, UTS, ductility and creep rupture ductility, should also be considered if possible.

However, the mechanical properties of metallic alloys depend on a high number of parameters, such as composition, heat treatments, mechanical treatments and testing temperature, and the design of a new alloy is generally the result of a long and expensive experimental work. Indeed, understanding the behaviour of the alloys as a whole is not possible for a human brain, and not all the interactions between the parameters are known.

For this reason, it is proposed here to perform a kind of "multi-dimensional non-linear empirical regression" of the final behaviour of a category of alloys as a function of all the elaboration parameters and testing conditions. To complete this task, new computing techniques, such as Artificial Neural Networks (ANN) and Gaussian Processes (GP) will be used.

Good information about these techniques can be obtained, for example, on Dr. D. MacKay's page (Department of Physics, University of Cambridge).

Modelling

The first step of the modelling approach is to gather a database, as big and as complete as possible, on the mechanical properties of alloys as a function of their elaboration parameters -composition, thermomechanical treatments, testing temperature-. These data have been obtained from our industrial partners and from the scientific literature. They concern the yield stress, Y, the ultimate tensile stress, UTS, the ductility, the creep rupture stress and the creep rutpure ductility of nickel-base superalloys, and the creep rupture stress of ferritic steels.

Up to now, the work concerned the Gaussian Processes modelling of the mechanical properties of nickel-base superalloys.

The models can then be used to make predictions on new alloys.

Testing the models

Trusting blindly the computer to design new alloys would be very risky ! Indeed, such models are accurate only if the database is "complete" and "homogeneous", i.e. if all the areas of composition, thermomechanical treatments and testing conditions are equally represented in the database, which is, in general, not the case. If not, predictions may be inaccurate in some areas of the database range. However, an indication of this is given by the softwares through error bars. Large error bars mean "the model is not confident in this area", and act as a warning signal.

Nevertheless, it is worth testing the model in simple cases where physical laws or metallurgical trends are well known.

Examples

First example : Influence of temperature on the yield stress of Nimonic 115

Schematically, nickel-base superalloys are consituted of a Ni-type matrix (gamma), which yield stress decreases with increasing temperature, and of Ni3(Al,Ti) inclusions (gamma'), which yield stress increases with temperature up to about 900oC and then drops rapidly to zero. The shape of the above curve results from the "competition" between the resistances of the two phases, and is very well predicted by the model.

Second example : Influence of the Ti/Al ratio on the yield stress of a 20%Cr-10%Co-0.03%C Ni-base superalloy

The titanium atom is 4% bigger than the aluminum one. Ti yields thus a larger solid solution strengthening of the inclusions than Al, and a larger gamma/gamma' lattice misfit -coherency strengthening-. It also provokes an increase in the anti-phase boundary energy of the gamma' phase, which renders more difficult the cutting of inclusions by dislocations.

This is well predicted by the Gaussian Processes model: the predicted yield stress increases with the Ti/Al ratio, as otherwise experimentally observed (Miller et al., Met. Trans., 8A (1977) 121-129).

Third example : Modelling the creep rupture stress (CRS) versus rupture time (tr) of a IN 939 superalloy

The model is able to predict the actual variation, at 870oC, of the creep rupture stress, CRS, of a IN 939 nickel-base superalloy as a function of rupture time, tr (in hours). The experimental points are from Delargy et al., Mat. Sci. & Tech., 2 (1986) 1031-1037.

Design of new alloys

Those models have be used as a basis and a guide for the conception of new alloys with the desired properties. However, it is also necessary to take the metallurgical knowledge and industrial requirements into account, which led to the following basic considerations:

- The aim of the project is to make a relatively cheap alloy. Consequently expensive elements like Co, Ta, Nb, Mo... have been eliminated.

- A relatively high chromium content is necessary to cope with the highly corrosive environment (steam at 750oC, fuel ash in boilers).

- Strengthening will be ensured by "low price" elements: Al, Ti (gamma' formers) and W (solid solution strengthener). However, the Al and Ti contents should be kept as low as possible since the gamma' phase decreases formability and weldability.

- Carbon should minimize the grain-boundary sliding creep mechanism through the presence of carbides.

- A small addition of boron can enhance the grain-boundary quality, and limit grain-boundary diffusion.

- A few % of Fe, even if it decreases the mechanical properties, will allow to use Cr-Fe industrial scrap and/or ferrochromium as a source of Cr instead of pure Cr, and thus to lower the price of the alloy.

- Finally, it has been taken into account that nickel-base superalloys usually contain little amounts of Si.

Following, several tens of new alloys having a priori the required mechanical properties have been proposed. However, such a conception doesn't take into account the microstructural stability of the alloys, and this point has been subject to a particular analysis. The promising new compositions have been entered in a thermodynamical simulation software (Thermo-Calc), to simulate the equilibium phases present in the alloys.

Finally, only a few alloys have been chosen on the basis of their mechanical properties, thermodynamical stability... and price.

Example

The relation between the creep rupture stress of the most promising alloy and its lifetime at 750oC has been predicted with the Gaussian processes model. This alloy is expected to match the requirement of a lifetime of 100000h under 100MPa, the cost of its contitutive elements being reduced of about 50% compared to usual commercial nickel-base superalloys with similar mechanical properties.

The equilibrium phases present in this alloy as a function of temperature (750oC) and above have also been predicted. Only the main gamma and gamma' phases, as well as carbides (M23C6 and TiC) and borides (TiB2) are expected at service temperature and higher. A chromium-based bcc phase is predicted to appear below 680oC. Such a phase is also predicted in a number of commercial alloys, but, given the low temperatures concerned, almost never forms.

From this diagram, the temperature ranges for heat and mechanical treatments can be determined: this alloy should be melted above 1380oC, solidified in the range 1380oC - 1350oC, and forged in the gamma'-free region between 1350oC and 1010oC. Then it should be solution heat-treated above 1010oC and aged below 1010oC.

Another parameter has also been predicted with a Gaussian process model: the gamma/gamma' misfit. It has been estimated to be close to zero at 750oC (-0.05%), which is an indicator of a good creep-resistant alloy.

Processing

The designed material is currently being experimentally manufactured by Special Metals (INCO). The usual industrial process includes casting, remelting, forging, and heat treatment. It has to be designed with respect to the alloy composition and properties, depending on the problems they might cause:

Vacuum Induction Melting (VIM)

A proper stirring must be ensured to prevent the high-density and high-melting point tungsten particles from sinking in the bottom of the melt instead of dissolving, which would result in irreversible macrosegregation.

Titanium can combine to O and N traces, and form oxide and nitride particles remaining as inclusions. However, in our case the aluminium content is high enough to combine preferentially to O and N, whose oxide and nitride particles float on the melt and can be removed easiliy.

Electro-Slag Remelting (ESR)

The above casting is usually made under the shape of an electrode for arc remelting. ESR is not necessary when the first cast is "perfect", i.e. without macrosegregation, cracks, etc., which is usually the case for low weights, typically less than 0.5 ton.

Hot working

The material can be forged, rolled or extruded (as already mentioned, above the gamma' solvus). In the case of forging of high weight ingots (> 0.5 ton), a typical problem is due to the rapid cooling of the surface below the gamma' solvus between forge passes, yielding to severe surface cracking. This usually does not occur for low weights and for extrusion, since the process is faster.

First results

The selected experimental alloy has been made in the laboratory by argon arc melting, in order to study segregation, phase formation, and age hardening.

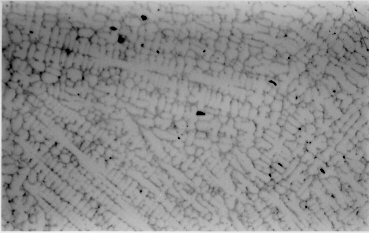

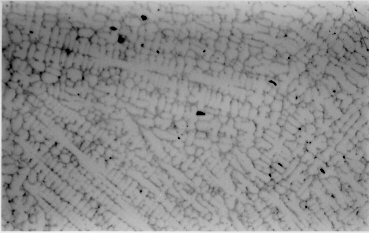

In the as-cast condition, the material presents a typical dendritic microstructure, with dendrites of several hundred of microns in length.

Image length: ~ 1 mm

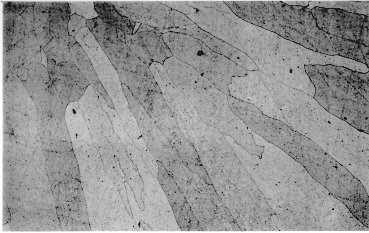

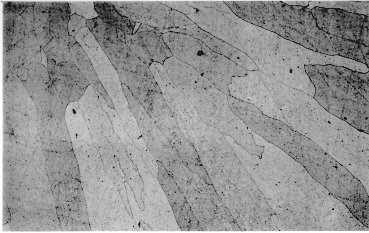

After high temperature solution heat treatment, microsegregation has been removed, and large grains have formed.

Image length: ~ 2 mm

Two ageing heat treatment steps have then been performed to precipitate gamma' inclusions. Following each step, Vickers hardness has been measured, and plotted as a function of the predicted equilibrium gamma' volume fraction at the corresponding temperature. Even if hardness is a complex property, its evolution with gamma' volume fraction roughly follows a simple Fleischer-Freidel precipitation hardening law, proportional to the square root of the volume fraction.

Vickers hardness of the new material, Hv,

as a function of the calculated gamma' volume fraction

Future work

The microstructure, phase formation and phase stability, and the mechanical behaviour of the industrially manufactured alloy will be investigated and modelled. In particular, new creep models, taking into account a possible evolution of the microstructure with time and/or deformation, should be defined.

Back to :

My personal page

The Phase Transformations Group

The Department of Materials Science and Metallurgy

The University of Cambridge