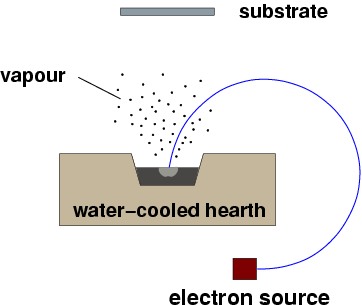

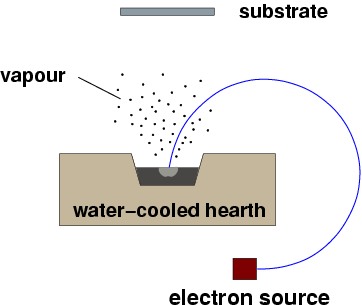

A simple EBPVD process, the whole assembly would be under vacuum. Rotation of the electron beam is obtained by a magnetic field perpendicular to the drawing.

| Introduction | Bond Coats | TBC | Processes | Resources | |

| [Introduction] [Thermal Spray] [EBPVD] | Back to phase-transformation home page |

As indicated by its name, electron beam physical vapour deposition belongs to the more general category of physical vapour deposition.

In these methods, film growth is obtained by condensation of a vapour on the substrate. The vapour can be produced by heating the consumable enough to obtain evaporation, or by mechanically knocking the atoms off (e.g. sputtering).

In EB-PVD, the evaporation is obtained with a focused electron beam, as illustrated below.

|

A simple EBPVD process, the whole assembly would be under vacuum. Rotation of the electron beam is obtained by a magnetic field perpendicular to the drawing. |

EBPVD and PVD methods in general are semi-line-of-sight, and produce a surface that replicates the original one (an initially smooth surface will result in a smooth coating).(DeMasi-Marcin, 1994).

As discussed in this section, EBPVD TBCs

offer vastly superior strain resistance compared to APS ones, due to their

columnar microstructure. EBPVD is therefore the preferred process for

application of these coatings.

Current research focusses on tailoring the structure of the deposited

coating. For example, directed vapour deposition (DVD) was used to obtain

a TBC with a zig-zag microstructure which offered a thermal conductivity as low

as APS TBCs while retaining strain tolerance (Levi, 2004).

| conditions of use | 2004 Thomas Sourmail. | Feedback greatly appreciated |