Professors Patricio Mendez and Adrian Gerlich, University of Alberta, kindly arranged for Harry to visit Edmonton, to see their new Welding Research Centre, deliver lectures and visit the massive developments in local industry related to steel and oil.

Submerged arc welding equipment for hardfacing steel plate, at Wilkinson Steel and Metals of Alberta, Canada |

The process in action |

|

Jack Tracy-Roth, Patricio Mendez and Harry |

About 50 Rockwell C hardness layers of deposit on top of mild steel plate |

At JV Driver Projects Inc. of Alberta, Canada. The Company fabricates steel and pipe and creates modules for building processing plants. Well-organised sets of welding bays |

|

Structural section following welding |

Complex shapes |

Welding in progress |

|

|

Bubba, a huge manipulator |

Jim Burrows (Driver's), Patricio Mendez (University of Alberta), Adrian Gerlich (University of Alberta) and Robert Henry (Driver's) |

Steel scrap arrives at AltaSteel Ltd. by train |

Steel scrap arrives at AltaSteel Ltd. by train |

|

The scrap is melted in an electric arc furnace. |

Electric arc furnace. The ladle at the bottom is awaiting the discharge of molten steel from the furnace |

Pouring of the steel into the ladle |

|

|

|

|

Continuous casting strands |

Strands being cut to length |

The cut lengths in stock |

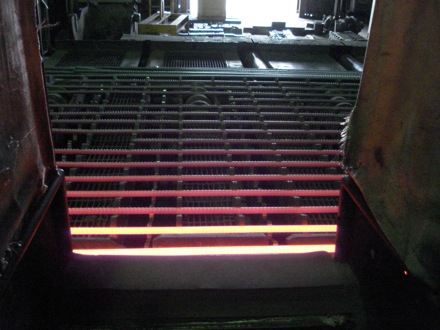

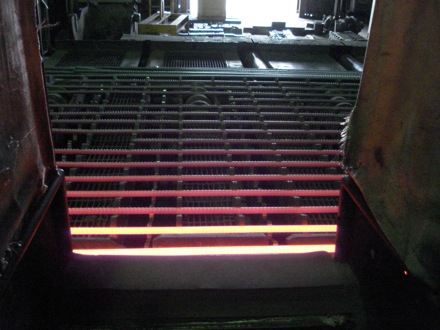

Hot rolling |

|

|

The bars in the cooling bay |

Professors Patricio Mendez and Adrian Gerlich. First stop at the Discovery Centre where there is an organised display of the "oil sand" deposits in Alberta and the process that leads to refined petroleum. |

Thick bitumen is extracted from the oil snad and upgraded into petroleum |

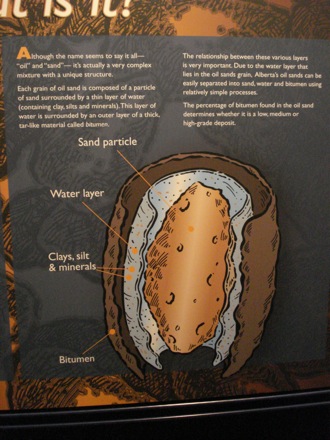

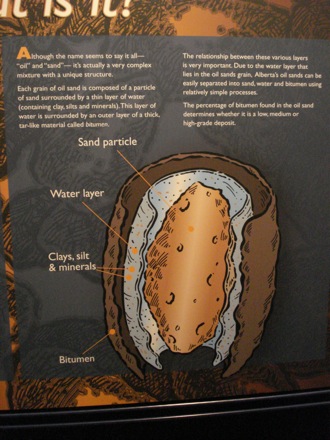

The complex microstructure of oil sand |

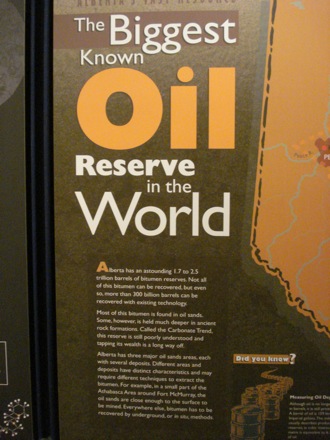

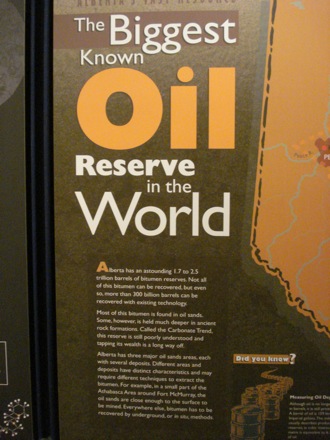

There is a huge reserve of oil in Alberta's oil sands, comparable to the entire reserves of Saudi Arabia |

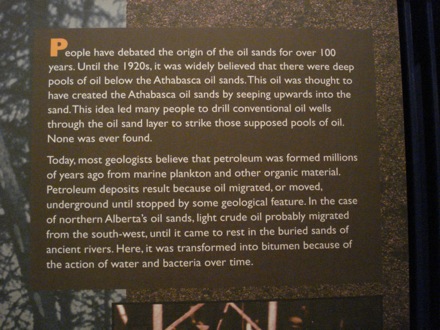

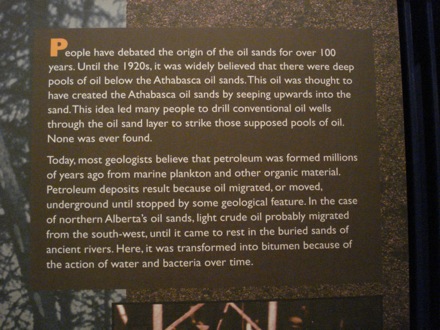

The origin of oil sands |

Core sampling drill. |

A bucket used to dig out the sand. This is a small bucket. |

The bucket teeth. |

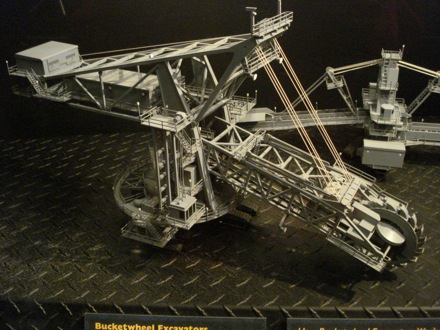

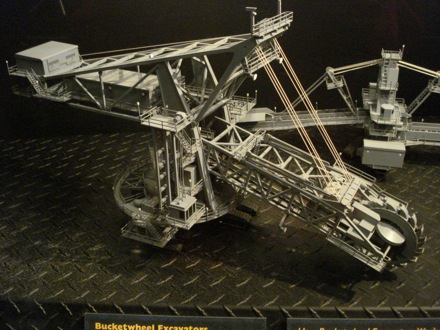

A bucketwheel excavator |

The structure behind the humans is a huge truck used to carry the sand |

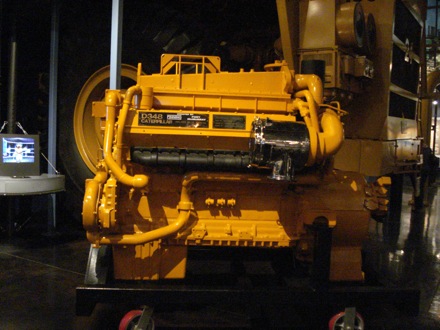

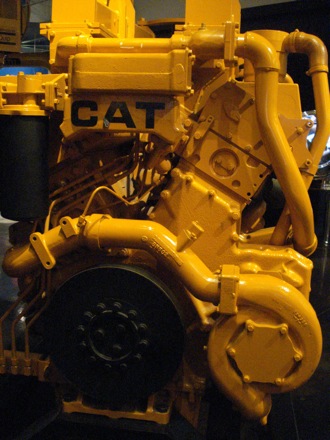

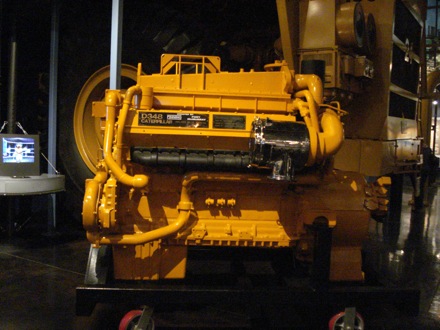

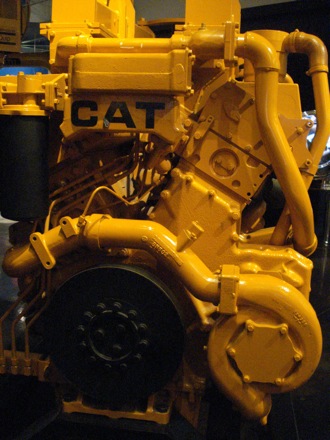

The powerhouse of the 400 tonne truck |

|

Compare the size of an ordinary car tyre against that of the truck. Each of the tyres of the truck costs about 60,000 dollars |

|

|

|

The tooth on the left is at the beginning, and the one on the right after it has been worn down by abrasive oil sand |

The wear is in spite of the hard layer deposited on the tooth. |

|

|

|

|

Patricio at the helm of the giant truck |

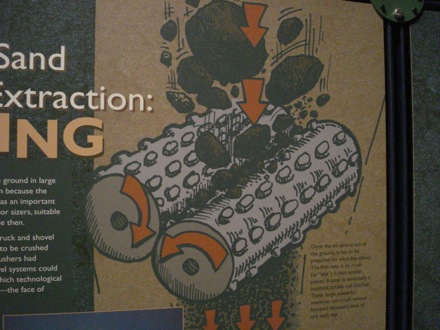

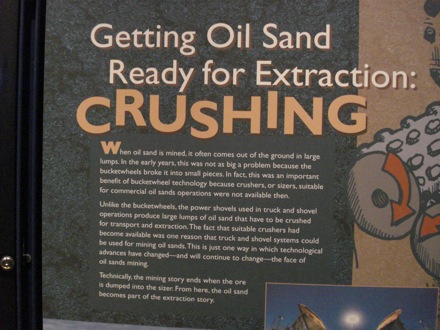

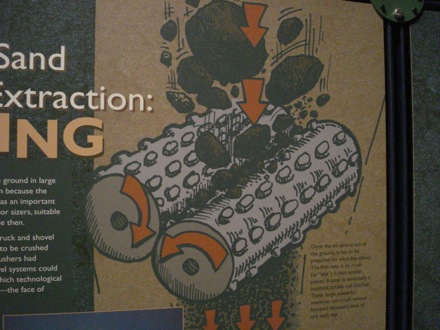

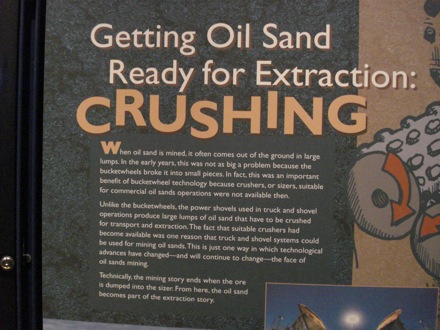

The oil sand dug out from open cast mines is processed through thinning, floatation and refinement to extract the oil. Another method involves pumping hot steam to underground layers of oil sand, and to pull out the liberated oil from the other pipe. |

|

This is an electrical socket to power heavy equipment. |

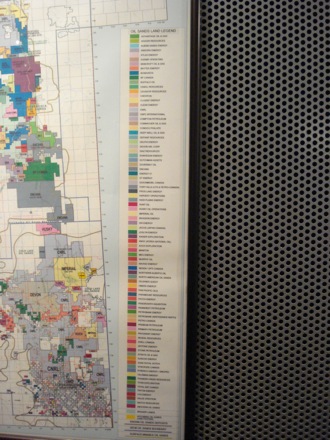

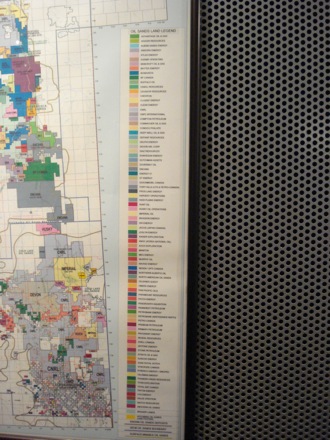

The different companies involved in the extraction processes |

Arrival at the Suncor oil sand mine near Fort McMurray, Alberta. This was the first such mine in Canada. |

Refinery in the background |

Refinery in the background |

We needed a robust truck to tour the mine. The first step was for Professors Mendez and Gerlich to overcome the intelligent theft prevention system which did not allow the truck to start. |

Patricio, pretending to help Adrian |

Help eventually arrived and we were off. |

The black material in the backgrond is the stockpile of oil sand |

|

The sulphur is extracted during the process. The yellow mountain in the background is the accumulated sulphur as a by-product from the oil extraction process, awaiting sale. |

|

|

|

|

|

|

Heavy trucks, typically 400 tonnes, transport the sand. Slurries are pumped through steel pipes. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Another sulphur mountain in the background

|

|

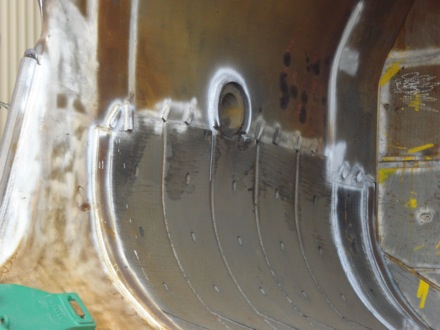

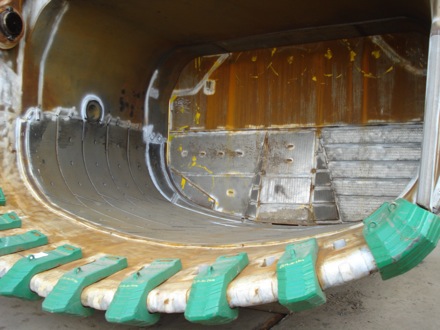

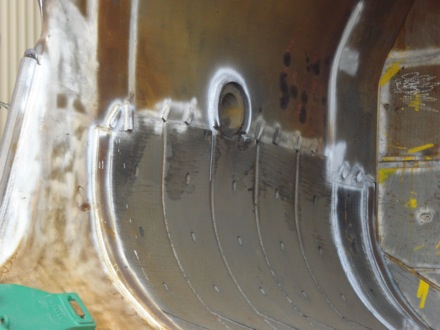

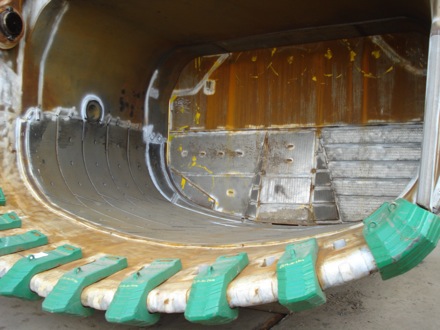

One of the digging buckets, just refurbished with hard, Cr-rich alloy deposited on the lower half of the bucket. The green teeth are engineered for easy replacement when they are worn after a few days of service. |

|

|

The lower halves of the vertical edges are coated with a tungsten-carbide/nickel alloy for additional wear resistance. |

|

|

|

|

|

|

The steel panels bolted together have polymer cores. |

Such composites are used for bridge or ship decks to reduce weight, with the polymer bonded to the steel helping to stiffen the section. |

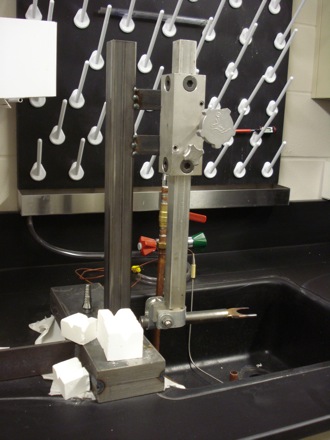

Fatigue testing of composite steel panel |

Bolted joint being fatigue tested |

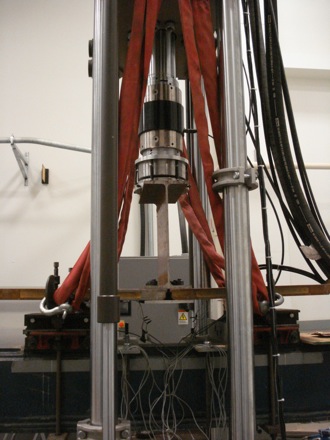

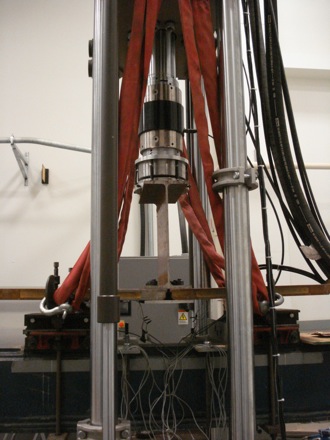

Very large mechanical testing machines used to induce combinations of shear and other loads for the purposes of evaluating seismic effects |

Shear damage |

|

|

|

Concrete beams tested to failure. Multiple cracking visible |

The Mackiw Lecture in Metallurgy, University of Alberta |

The Mackiw Lecture in Metallurgy, University of Alberta |

The Mackiw Lecture in Metallurgy, University of Alberta |

The Mackiw Lecture in Metallurgy, University of Alberta |

The Mackiw Lecture in Metallurgy, University of Alberta |

Hugh Roth, now working for the oil sands industry, did his Ph.D. studies in Cambridge |

The city of Edmonton viewed from a rotating restaurant, La Ronde |

|

|

|