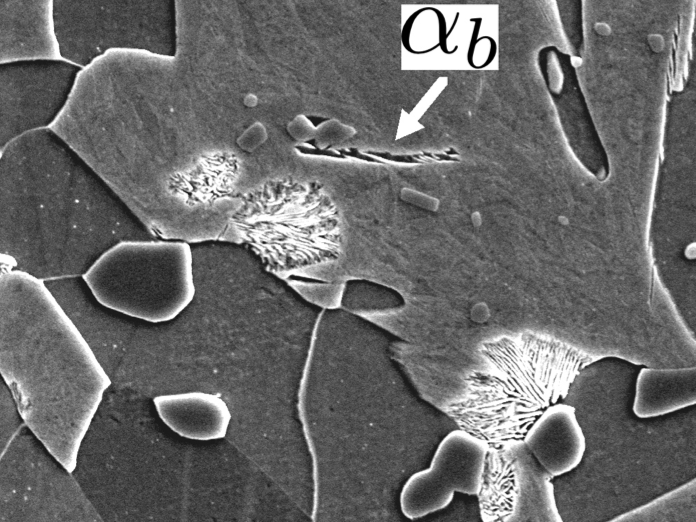

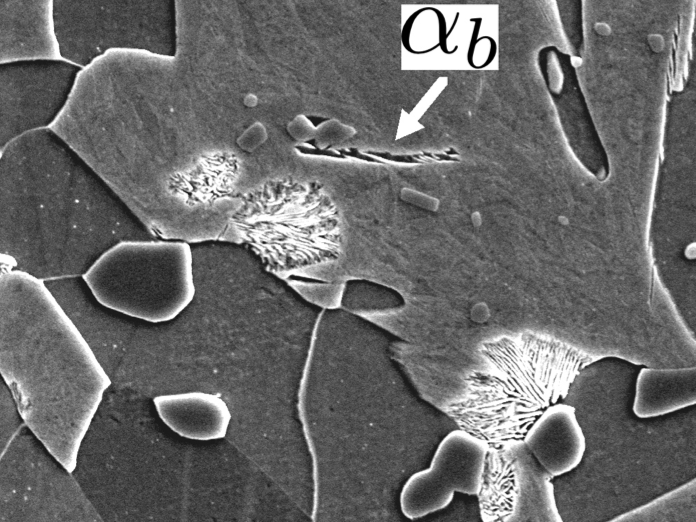

The response of a strong bainitic-steel to tempering at high temperatures is investigated, because a softened state is sometimes necessary during the manufacture of engineering components, prior to the final heat-treatment which hardens the material. Thermodynamic calculations conducted to determine the maximum temperature at which the steel could be annealed without forming austenite were found to significantly overestimate the actual temperature at which austenite, ferrite and cementite (γ + α + θ) can coexist in equilibrium. As a consequence, the tempering temperature must be limited to below about 700°C, which unfortunately necessitates many days of tempering in order to reduce the hardness to less than 250 HV. An alloy modification which may shorten this tempering time is suggested. One unexpected outcome is that the unintended heat treatment in the three-phase field revealed useful information about the nucleation of pearlite on cementite particles. Colonies of pearlite started inevitably on particles of cementite located at the γ/α interfaces, rather than at similar particles enclosed completely by the austenite.

International Journal of Materials Research 103 (2012) 1319-1324

| Envelope | Coefficients | Filling welds | Hot | Delta |

| Satoh | Fields | Piping | European welds | Poles |

| Mixed | Creep | Extraordinary ductility | Problems | Mechanical stabilisation |

| PT Group Home | Materials Algorithms |