Investigations into the Microstructure-Toughness Relation in High-Frequency Induction-Welded Pipes

Ö. E. Güngör, P. Yan, P. Thibaux, M. Liebeherr, H. K. D. H. Bhadeshia and D. Quidort

Abstract

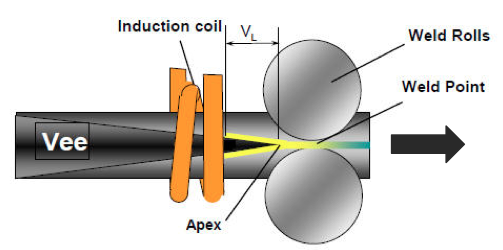

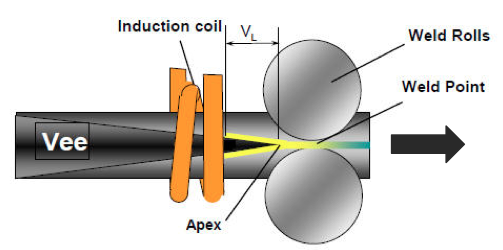

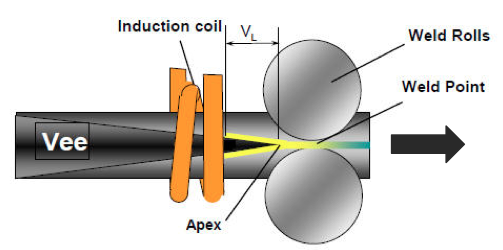

In the present paper, investigations performed on ArcelorMittal X65 linepipe steel in order to understand the effects of high frequency induction welding process and in-line post-weld heat treatment on weld properties are described. The factors that potentially can affect weld toughness, such as microstructure, grain size, precipitates, hardness, inclusions, and texture, are evaluated and discussed systematically in order to correlate weld microstructure with toughness of the HFI welded pipes.

8th International Pipeline Conference, 2010, published by the American Society of Mechanical Engineers, Alberta, Canada, IPC2010-31372, 1-9.

Download PDF file of paper

Related Papers

- "Crystallographic Texture of Induction-welded and Heat-treated Pipeline Steel"

Advanced Materials Research, 89-91 (2009) 651-656.

P. Yan, Ö. E. Güngör, P. Thibaux and H. K. D. H. Bhadeshia

- "Induction welding and heat treatment of steel pipes: evolution of crystallographic texture detrimental to toughness"

Science and Technology of Welding and Joining, 15 (2010) 137-141.

P. Yan, Ö. E. Güngör, P. Thibaux and H. K. D. H. Bhadeshia

- "Air-Cooled Bainitic Steels for Strong, Seamless Pipes Part 1: Alloy Design, Kinetics and Microstructure"

Materials Science and Technology, 25 (2009) 1502-1507.

G. Gomez, T. Pérez and H. K. D. H. Bhadeshia

- "Air-Cooled Air-Cooled Bainitic Steels for Strong, Seamless Pipes

Part 2: Properties and Microstructure of Rolled Material"

Materials Science and Technology, 25 (2009) 1508-1512.

G. Gomez, T. Pérez and H. K. D. H. Bhadeshia