In Part 1 of this study two alloy systems were designed in order eventually to facilitate the production of seamless pipes without the additional quench and tempering heat treatment that is currently a part of the manufacturing process. The alloys were shown to reliably produce the desired microstructure of carbide-free bainite under conditions appropriate to industrial parameters. The work reported here deals with the next stage in the development, i.e., the study of the microstructure and properties of the alloys in the hot-rolled condition. The experimental techniques have been described in Part 1 and hence are not repeated here.

Materials Science and Technology, 25 (2009) 1508-1512.

Download high resolution images

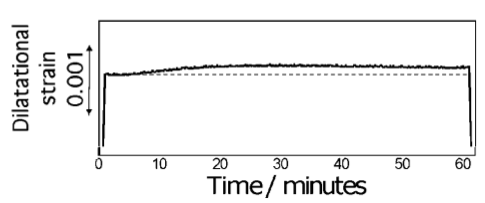

Data for Alloy 1, normalised state

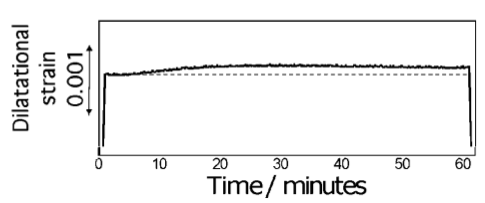

Data for Alloy 2, heat-treated state

Photographs showing the manufacture of seamless pipes

| PT Group Home | Materials Algorithms |