Tenaris Siderca, Campana, Buenos Aires, Argentina

Iron is made by direct reduction of iron ore and natural gas. Scrap metal is also a part of the process.

Iron is made by direct reduction of iron ore and natural gas. Scrap metal is also a part of the process.

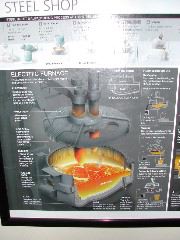

Schematic of the electric arc furnace.

Ladle being lined with ceramic.

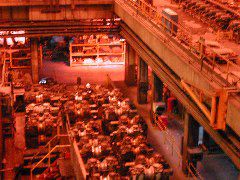

The steel production plant. Electric arc furnace in the background.

The devices for pouring molten iron into the continuous casters.

The device for pouring molten iron into the continuous casters.

Ladles being preheated in a horizontal position. The preheating is needed to reduce the thermal shock when molten iron is poured in.

Hot ladle, ready to receive molten iron.

Hot ladle, ready to receive molten iron.

The red hot components are special ceramic tubes for pouring molten iron from the ladle into the continuous casters below.

The red hot components are special ceramic tubes for pouring molten iron from the ladle into the continuous casters below.

Semi-solid continuously cast billets emerging from vibrating copper (water cooled) moulds in the caster.

Semi-solid continuously cast billets emerging from the caster.

Semi-solid continuously cast billets emerging from vibrating copper (water cooled) moulds in the caster.

Continuously cast billets.

Continuously cast billets emerging from the caster on the left, out of view.

Carbon electrodes in the arc furnace.

Mandrel piercing mill for making pipes from red-hot solid ingots.

Mandrel piercing mill for making pipes from red-hot solid ingots.

Pipe emerging.

Pipe emerging.

The mandrels.

The finished pipes, which are then cut into practial lengths after non-destructive inspection.

Stocks of pipes.

Pipes are austenitised, and quenched using a quenching unit which sprays water, or by dropping into this quench tank.

Pipe emerging from the quenching unit.

Pipe emerging from the quenching unit.

A peek into the austenitisation furnace.

Coming out of the furnace.

Pipe-straightening rolls.

Pipe-straightening rolls with a pipe going through.

Pipe-straightening rolls with a pipe going through.

Stocks of steel pipes.

The team.

The original pilger mill at the Tenaris plant.

The original pilger mill at the Tenaris plant.

The threaded end produced on some of the pipes. The quenched and tempered pipes are frequently joined mechanically.

Corrosion testing device in which a tensile specimen is statically loaded, immersed in a solution such as salt water, and hydrogen sulphide bubbled through. The blue ring is the load appliation mechanism.

A different experiment to measure corrosion due to sulphide.