Photograph courtesy

of David Warrington,

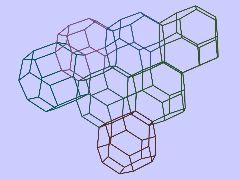

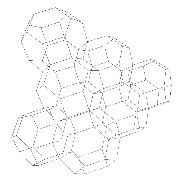

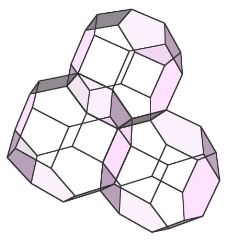

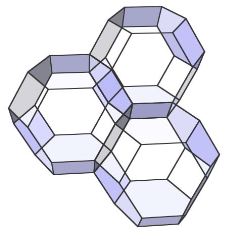

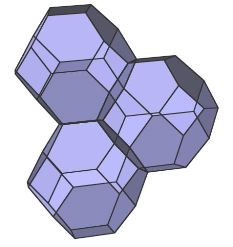

tetrakaidecahedron

The effect of plastic deformation on the grain boundary surface area per unit volume and edge length per unit volume is examined using two methods. First, by applying homogeneous deformations to tetrakaidecahedra in a variety of orientations, and then by using the principles of stereology. It is shown that the methods produce essentially identical results. It is now possible to calculate changes in the grain parameters as a function of a variety of deformations, for combinations of deformations, for complex deformations, and for cases where it is not necessary to assume an idealised grain microstructure.

Materials Science and Technology 23 (2007) 757-766.

Photograph courtesy |

A short audio interview of Harry Bhadeshia by Mathew Peet, on the content of the paper.

| MAP_STEEL_TOPOLOGY | PROGRAM: Topology of grain deformation, permitting calculation of grain surface and edge as a function of strain for a variety of deformation modes. |

The following images have kindly been provided by Professor Rongshan Qin, POSTECH, Korea.

|

|

|

|

|

|

The following links show additional examples of the kind of processing where the work enshrined in the paper can be exploited.

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Mechanicallly Alloyed | Theses | Retained Austenite |

| PT Group Home | Materials Algorithms |