At POSCO Special Steels, Changwon City.

At POSCO Special Steels.

At POSCO Special Steels.

Rongshan Qin ready to explore POSCO SS, Changwon city.

Mr Han, Bruno and Harry

The founder of the original company which eventually became POSCO Special Steels

The founder of POSCO Special Steels

Carbon electrodes for the arc furnace

The new, giant 10,000 tonne force forging press

A giant manipulator for handling hot ingots during forging

The manipulator arms, made of highly alloyed (with Ni, Mo) heat-resistant steel

Compare the size of the arms against the human hands on the right!

The manipulator arms, made of highly alloyed (with Ni, Mo) heat-resistant steel

The press, in the process of installation

Lowering some infrastructure into a pit adjacent to the press.

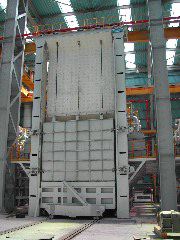

Bank of furnaces for preheating ingots and for subsequent heat treatment

One of the furnaces with its huge hanging door.

Inside the continuous casting plant.

Inside the continuous casting plant.

Inside the continuous casting plant.

The strands emerging from the vibrating moulds.

Continuous casting of strands at KISCO, used for making concrete reinfocement bars.

Continuous casting of strands at KISCO, used for making concrete reinfocement bars.

Continuous casting of strands at KISCO, used for making concrete reinfocement bars.

Rolling down into the required size of reinforcement bar.

A set of moulds.

The continuously cast strands emerging bending into a horizontal position.

The continuously cast strands emerging bending into a horizontal position.

The continuously cast strands emerging bending into a horizontal position.

Continuous casting of strands at KISCO

Continuous casting of strands at KISCO

The ladle pouring steel into the continuously casting vibrating-moulds.

The ladle pouring steel into the continuously casting vibrating-moulds.

Ladles

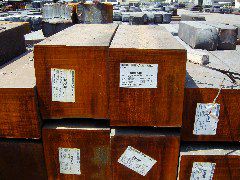

Ingots of special steels.

Ingots of special steels.

Ingots of special steels.

Ingots of special steels.

Ingots

Forging in progress.

Forging in progress.

Forging in progress.

Forging in progress.

Forging in progress. You can see the ingot rotated by the manipulator on the right in this sequence of photographs.

Putting ingot into a reheating furnace.

Reheating furnace.

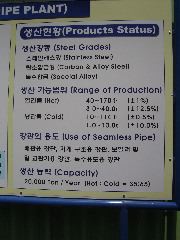

The making of seamless tubing, mostly stainless and other special steels, at POSCO Special Steels

The drilled stainless steel ingots.

The drilled stainless steel ingots.

The drilled stainless steel ingots.

The tube-making plant with induction heaters.

The hot ingot of stainless steel.

Stainless steel tubes, seamless.

In Gee Kim, getting the feel of steel.

Ready for dispatch

Stainless steel wire-rod.

Stainless steel wire-rod.

Stainless steel wire-rod.

This is before the pickling operation.

This is after the pickling operation.

Ready ot ship.

Stainless steel wire-rod.

A stainless steel coil emerging from a hot furnace ready for quenching in water.

Stainless steel.

Stainless steel

Stainless steel.

Stainless steel.

Stainless steel.

The Stainless steel is made from high-quality scrap using an electric arc furnace.

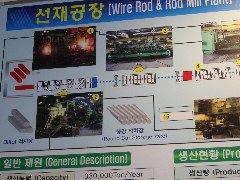

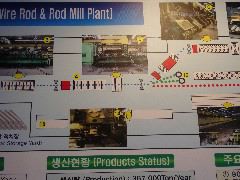

Wire and rod mill at POSCO Special Steels.

The cooling bay.

POSCO Special Steels

At the Korea Iron and Steel Company, KISCO

At the Korea Iron and Steel Company, KISCO

At the Korea Iron and Steel Company, KISCO

The strip used to make welded tubes. All produced from scrap using an electrical arc furnace.

The strip used to make welded tubes. All produced from scrap using an electrical arc furnace.

The tube mill at the Korea Iron and Steel Company (KISCO)

Sheets are formed into a tube, seam welded and then drawn.

Pipes.

Pipe stacks at KISCO.

Pipe stacks at KISCO.

Notice the seam welds.

Pipe stacks at KISCO.

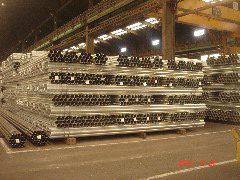

Galvanised pipes at KISCO.

Galvanised pipes at KISCO.

Galvanised pipes at KISCO.

Galvanised pipes at KISCO.

Galvanised pipes at KISCO.

Zinc ingots, used in the galvanising process.

Zinc ingots, used in the galvanising process.

The electric arc furnace viewed from inside the control room.

The electric arc furnace viewed from inside the control room.

Reinforcement bar.

Reinforcement bar.

Reinforcement bar.

Reinforcement bar.

Reinforcement bar.

The team at the Korea Iron and Steel Company, KISCO

The team at the Korea Iron and Steel Company, KISCO

Large ingots, forged and then machined for propellor shaft in marine applications.

Large ingots, forged and then machined for propellor shaft in marine applications.

At the Doosan Heavy Industries factory.

At the Doosan Heavy Industries factory.

At the Doosan Heavy Industries factory. They make nuclear power plant, thermal electricity generation plant, are the worlds largest manufacturers of desalination equipment, construction projects etc.

At the Doosan Heavy Industries factory. They make nuclear power plant, thermal electricity generation plant, are the worlds largest manufacturers of desalination equipment, construction projects etc.