Modelling the coarsening behaviour of TiC precipitates in high-strength, low-alloy steels

J. H. Jang, C. H. Lee, H. N. Han, H. K. D. H. Bhadeshia and D. W. Suh

Abstract

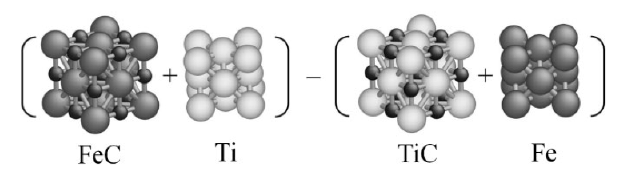

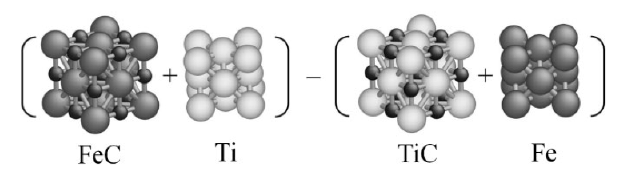

Some of the most modern automotive-sheet steels rely on a dispersion of fine precipitates based on TiC, generated during the major phase changes that occur as the rolled material is cooled to the coiling temperature. The coils themselves cool extremely slowly, thus leading to the coarsening of the precipitates and a loss of strength. Beginning with a calculation of the interfacial energy, the precipitate coarsening kinetics are modelled as a function of the stoichiometry of titanium and carbon. The purpose was to assess the influences of interface energy and Ti/C stoichiometry which limit the rate at which the dispersion coarsens by the diffusion of solute from the small to the larger particles. It is found that Ti/C ratio plays a critical role; a titanium concentration which is slightly less than required to combine with carbon leads to a dramatic reduction in the coarsening rate.

Materials Science and Technology 29 (2013) 1074-1079.

Download paper

Coarsening of domains in Universe

Coarsening of dendrites