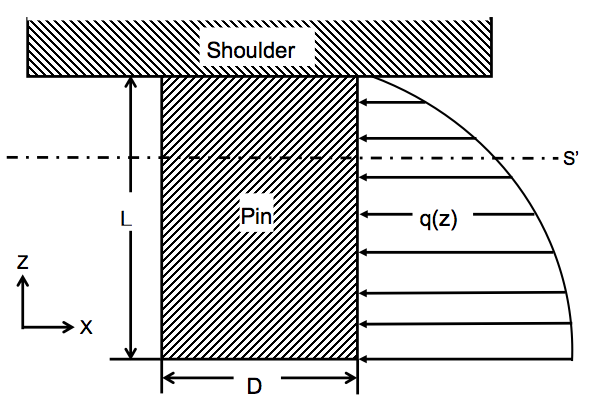

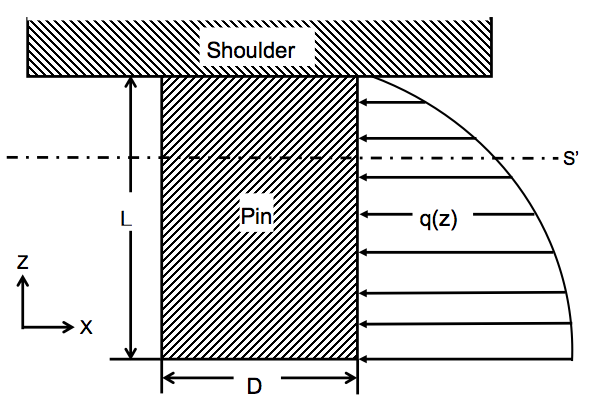

Friction stir welding is not used for hard alloys because of premature tool failure. A scheme is created which exploits the physical three-dimensional heat and mass flow models, and implements them into a fast calculation algorithm, which when combined with damage accumulation models, enables the plotting of tool durability maps which define the domains of satisfactory tool life. It is shown that fatigue is an unlikely mechanism for tool failure, particularly for the welding of thin plates. Plate thickness, welding speed, tool rotational speed, shoulder and pin diameters and pin length all affect the stresses and temperatures experienced by the tool. The large number of these variables makes the experimental determination of their effects on stresses and temperatures intractable and the use of a well tested efficient FSW model a realistic undertaking. An artificial neural network, trained and tested with results from a phenomenological model is used to generate tool durability maps that show the ratio of the shear strength of the tool material to the maximum shear stress on the tool pin for various combinations of welding variables. These maps show how the thicker plates and faster welding speeds adversely affect tool durability and how that can be optimized.

Proceedings of the Royal Society of London - A, 468 (2012) 3552-3570.

| Envelope | Coefficients | Filling welds | Hot | Delta |

| Satoh | Fields | Piping | European welds | Poles |

| Mixed | Creep | Extraordinary ductility | Problems | Mechanical stabilisation |

| PT Group Home | Materials Algorithms |