Precipitates in creep resistant austenitic stainless steels

T.Sourmail

Department of Materials Science and Metallurgy

Pembroke Street, CB2 3QZ Cambridge, U.K.

Austenitic stainless steels are, by far, the most widely used stainless steels

comprising 70-80% of stainless production [1].

With excellent corrosion and mechanical properties at high temperatures,

they are choice materials for powerplant tubes which have to operate at

temperatures above 950K, or for aeroengines.

The important role of precipitation in the achievement of good creep properties

has been understood for long and extensively studied. Although some phases are

now well documented, there are still contradictions and missing

thermodynamic data, in particular, there is only a limited amount of

informations about phases like Z-phase or

Cr3Ni2SiN which can be predominant

precipitates in nitrogen bearing steels.

This paper is a review of common precipitates in austenitic stainless

steels, in particular wrought heat-resistant steels of the AISI 300 families or

20/25 steels. Precipitates forming in age-hardening austenitic stainless steels

are only briefly presented, having been previously reviewed by other authors.

Austenitic stainless steels are essentially

alloys of Fe-Cr-Ni, which owe their name to

their room temperature austenitic structure. The addition of chromium

has long been known to improve corrosion resistance. Cr is also a `ferrite

stabiliser' and Fe-Cr stainless steels have a ferritic structure, possibly

martensitic depending on the heat-treatment. The addition of austenite

stabilising elements in sufficient quantities can allow an austenitic

structure to be stable at all temperatures.

Nickel is the basic substitutional element used for austenite

stabilisation.

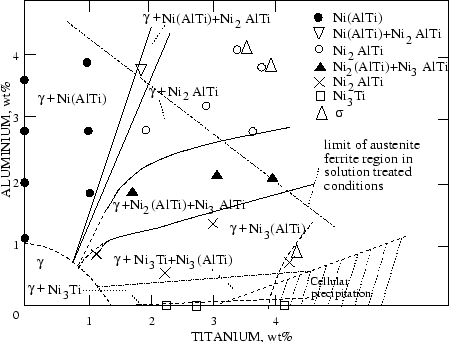

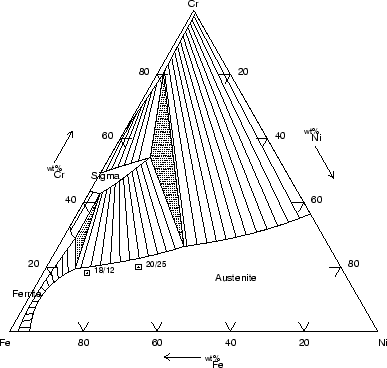

The equilibrium phases depend on the proportion of the three elements, as

well illustrated in an isothermal section of the ternary diagram for Fe-Cr-Ni

(fig. 1) calculated with MT-DATA [2].

Figure:

Isothermal section of the Fe-Cr-Ni diagram at

750  C: a typical 18Cr-12Ni wt% lies in the austenitic field.

Calculated using MT-DATA and the SGTE database.

C: a typical 18Cr-12Ni wt% lies in the austenitic field.

Calculated using MT-DATA and the SGTE database.

|

Often, alloying elements, either interstitial such as C or N,

or substitutional such as Mo, Mn, Ti, Nb, V, W, Cu, Al,... are used to

obtain the required properties.

They can be classified as ferrite-stabilisers or austenite-stabilisers and

their effect in this respect is often approximated using the notion

of chromium and nickel equivalents, calculated by formulae like

[3]:

In this example, the composition has to be given in weight%.

The use of such formulae is not always straightforward, as they refer to

the austenite

content, which is modified by various precipitation reactions involving these

elements.

Whether the austenitic structure is retained at room temperature

depends on the MS (martensite-start) temperature. Several empirical

formulae have been derived to describe the effect of chemical composition

on MS, an example is

[1]:

A typical type 304 (austenitic stainless steel) has its MS well below

room temperature.

However,

one should keep in mind that deformation-induced martensite formation can

occur well above MS. Md30 is the temperature at which 50%

of martensite has formed for a true strain of 30%. Again, formulae like:

have been derived to describe the effect of alloying elements

[1].

At high temperatures, a steel containing 18Cr, 12Ni wt% should

be fully austenitic. However, the addition of alloying elements often results

in the

formation of carbides, nitrides and intermetallics. These phases are not

always desirable and a good knowledge of precipitation reactions is required

to avoid loss of mechanical or chemical properties. A good example is the

sensitisation of non stabilised austenitic stainless steels: sensitisation

occurs when the precipitate

M23C6 forms at grain boundaries, depleting the

chromium content in the vicinity, which eventually results

in intergranular corrosion. This can be avoided by tying up the carbon with

strong carbide formers like Ti. The steel is then called stabilised.

These second phases will be presented in detail in a next section.

From a simple type 304 to the recent NF709, austenitic stainless steel

composition

covers a large range. The two main alloying elements are

chromium and nickel, so the steels will often be referred to

by their content of Cr and Ni. For example, 18/10 refers to an austenitic stainless steels with

18Cr, 10Ni wt% .

Table:

Composition of two austenitic stainless steels

| Wt% |

C |

Mn |

P |

Ni |

Cr |

|

| Type 304 [4] |

0.07 0.07 |

2.00 2.00 |

0.04 |

8-10 |

17-19 |

|

| NF-709 [5] |

0.06 |

1.00 |

0.006 |

25 |

20 |

|

| Wt% |

Mo |

Nb |

Ti |

B |

N |

Si |

| Type 304 |

0 0 |

0 0 |

0 0 |

0 0 |

0 0 |

0 0 |

| NF-709 |

1.5 |

0.26 |

0.05 |

0.005 |

0.167 |

0.40 |

|

The AISI 300 specifications for the compositions of different

austenitic stainless steels (wt%) is shown in table 2 (after [4]).

Grades denoted L contain low carbon (0.03 wt%) and N contain nitrogen

(eg: 316LN).

Most often used as creep-resistant steels are types 316, 321 and 347, or

alloys containing all of Mo, Nb and Ti.

There are many other variants of these compositions, like the japanese SUS300

series which mirrors the AISI 300 series, but with sometimes addition of both

Ti and Nb. For convenience, as is sometimes done in the literature, the AISI 300

series will be used even for steels not strictly belonging to it, like a 316 with

Ti addition.

In fact, it is not the intention to describe, in this review, the precipitation

sequences in all different grades of creep resistant austenitic stainless

steels, but rather to examine the occurrence of the various precipitates in

such a way that precipitation behaviour of non documented grades could be

inferred from the conclusions reached.

There is a large amount of material on the precipitation phenomena in the 300

series of alloys, which have been used widely as creep resistant steels.

The same is true for 20Cr-25Ni steels. However, it appears that the

long-term behaviour of Ti, Al alloyed austenitic stainless steels (type A286)

is very little documented [6]. This is possibly because

production difficulties have restricted the application of such steels to parts

requiring relatively small ingot sizes (aeroengine turbine discs), the design life

of which is much shorter than the few 100000 h required for a steam plant

[7].

- Mn has been introduced in austenitic stainless steels as a substitute for Ni during shortages

in the international market or for economical reasons. The nickel content can

be halved to 4 wt% by the addition of 2-6Mn wt%. However, although

the austenitic

structure is achieved, such steels do not exhibit the same corrosion resistance

as an 18/8 steel. Mn is also used to increase the solubility of nitrogen in

austenite.

- Mo is on the contrary a ferrite stabiliser. It improves the creep

properties of stainless steels by solid solution hardening. It also facilitates

carbides precipitation. However, it promotes

and Laves phase

formation on long term ageing.

and Laves phase

formation on long term ageing.

- Stabilising elements like niobium, titanium and vanadium greatly improve

the creep strength of austenitic stainless steels mainly by precipitating fine carbides

intragranularly. On the other hand, they reduce the creep ductility. The ratio

in which they are added to carbon is important to maximise the strengthening

effect and avoid precipitation of detrimental phases.

They can also have a solid solution strengthening effect.

- Carbon acts principally by solid solution strengthening in non-stabilised

grades, but mainly by precipitation strengthening when Nb, Ti or V are present.

- Nitrogen is a strong austenite stabiliser. It has also a role in

increasing the creep life of austenitic stainless steels:

it can act like carbon in stabilised stainless steel by

precipitating in the form of titanium or niobium nitrides, but the

nitrogen remaining in solid solution has also a much greater strengthening

effect than carbon. It has been believed to also lower the diffusivity of

chromium and carbon in the matrix, therefore delaying coalescence of

precipitates [1],[4]. However, more recent results

indicate that nitrogen enhances chromium diffusion, but retards the nucleation

of

M23C6 because of its low solubility in this carbide [8].

The formation of MX precipitates in austenitic stainless steels occurs when strong carbides/nitrides

formers (Ti, Nb, V, Zr, Ta...) are added to the alloy.

These additions have two purposes:

- stabilising the alloy against intergranular corrosion. When stabilisation

is the first aim, a stabilising heat-treatment is conducted at 840-900

C

for several hours before service. Most of the carbon is then `tied-up' by

precipitation of MC.

C

for several hours before service. Most of the carbon is then `tied-up' by

precipitation of MC.

- providing good creep resistance: when this is the first aim, a

solution heat-treatment is given in order to dissolve as much MX as possible.

Subsequent precipitation occurs during creep and increases strength. A typical

solution treatment is 30-60 min at temperatures between 1100 and 1250

C.

C.

The second use is the one we will focus on.

Many studies have concentrated on MX precipitation, but also on the

appropriate content necessary to obtain the best properties. The solubility

of the MX precipitates and the stoichiometry are essential in determining the

behaviour of the steel with regard to precipitation.

MX carbonitrides have a NaCl fcc (face-centered cubic)

structure, with lattice parameters as listed in table 3.

Table:

Lattice parameter of some MX precipitates.

| MX |

a, Å |

ref |

| NbN |

4.39 |

JCPDS 38-1155 |

| NbC |

4.47 |

JCPDS 38-1364 |

| TiN |

4.24 |

JCPDS 38-1420 |

| TiC |

4.33 |

JCPDS 32-1383 |

|

Often, measured lattice parameters have intermediate values,

reflecting the

existence of a solid solution between the different carbonitrides.

MX precipitates usually form on dislocations within the matrix, on

stacking-faults (most often with TiC), on twin and grain

boundaries. They have a characteristic cuboidal shape after sufficient ageing.

Stabilisers such as Ti or Nb have long been known to reduce the solubility

of carbon in austenite. Early studies of the problem consisted in the

determination of two parameters: H, the heat of solution, and A, a constant as

in:

where [M] is the weight percent of stabilising element in solution in

the matrix, and similarly for [C]. The product [M][X] is often referred to as

the solubility product. Strictly speaking, H is expressed in

K-1.

The two following relationships can be found in many publications

(e.g. [3],[4]):

They are essentially valid for a typical 18/12 steel, the concentrations

are in weight percent.

For a 20/25 steel, Kikuchi et al. [9] used for TiC H=10475, A=3.42

and for NbC, H=7900 and A=4.92, but it is not clear whether these values have

been measured for 20/25.

The solubility is, as shown in their work, an important factor in the

achievement

of good creep properties: they showed that adding M and X in excess of their

solubility limits resulted in coarse MX in the matrix and

induced faster coarsening of MX later precipitated. However, until this limit

is reached, the more M and X added the better because more MX particles will

be formed.

It is therefore clear that knowing the solubility limits of

MX carbides is

important. However, modern high-temperature austenitic stainless steels often contain both carbon

and nitrogen, and more than one strong carbide former (Ti+Nb, Nb+V...), and

relationships as above are of limited use when it comes to estimate

the solubility of multicomponent carbonitrides (e.g. (Ti,Nb)(C,N)).

Recently, some studies proposed

different approaches to the problem of the solubility of multicomponent

carbonitrides in austenite (P.Rios [10], [11], Zou et al.

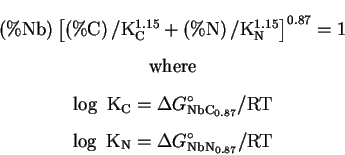

[12]...). For example, Rios [10] proposed for Nb(C,N):

However, one must notice that all these studies deal with MX in austenite for

micro-alloyed steels. It seems clear, from the literature, that the presence

of Ni and Cr introduces a further difficulty in austenitic stainless steels, the main one being the

formation of Z-Phase.

There is a general agreement that Z-Phase (CrNbN) forms in Nb

stabilised austenitic stainless steels, with a sufficient amount of nitrogen.

In fact, it seems that as soon as 0.06N wt% is present in a

typical 347 steel, Z-Phase can be expected (Hughes, [13]).

Moreover, in Cr/Ni steels, MX precipitates have been reported

to start growing largely under-stoichiometric (Andrén et al. [14],

[15]).

No approaches have been found that dealt with the solubility of multicomponent

carbonitrides in austenitic stainless steels susceptible of Z-Phase formation. Indeed, Z-Phase is

even absent from the SGTE (Scientific Group Thermodata Europe)

thermodynamic databases accessed by programs such as MT-DATA or Thermocalc.

A number of studies have been devoted to the determination of the correct

quantities of M and X to use in order to have the best mechanical

properties. As stated above, one factor is the solubility of MX. This has

been clearly outlined by the work of Kikuchi et al. [9].

The second factor is the proportion of each element that has

to be added, in

such a way as to maximise the amount of precipitation for a given product

[M][X]. It is also important to know, if stoichiometry is not respected,

which of the elements is in excess, as this may influence the precipitation

sequence.

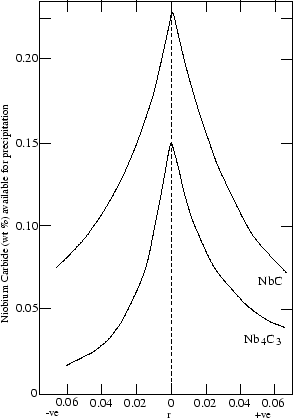

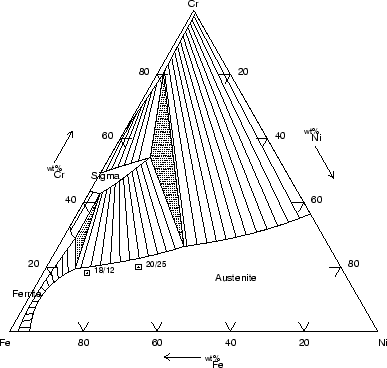

Wadsworth et al. [16] proposed a quantitative approach to stoichiometry and showed that the amount of precipitate that can form

drops quite sharply when M and X are not added in proportions corresponding

to the composition of the expected carbide (figure 2). Using the data of Keown and Pickering [17], they showed that best creep lives were

obtained when the Nb/C ratio was matching the stoichiometry

Nb4

C3 (for 18/12 or 18/10).

Figure:

The amount of niobium carbide available for

precipitation at 923K (after solution treatment at 1373K) as function of

the degree of deviation from stoichiometry r, defined by

r=pBT-qAT, where p and q are the mass fractions of A and B in the

compound ABn, and AT and BT the mass fraction of these elements in

the alloy. After [16]

|

Other studies have shown that best creep life was obtained for a

Nb/C atomic ratio of 1/1 (Adamson and Martin [18], Kikuchi et al.

[9], all for 20/25).

The work done by Kikuchi et al. does not highlight any serious contradiction

since the first composition they tried around the atomic ratio

1:1 was 2:1, which means that any variation within this interval was not

investigated. However, Adamson and Martin have results for the weight ratios

8:1 and 10:1 (respectively atomic ratios 1:1 and 4:3), but find better creep

properties for the 1:1 atomic ratio. A possible explanation is that NbC

actually forms with the stoichiometry 1:1 in 20/25 steels.

It seems important to note that all these studies rely on relatively

short term creep tests (as an average, less than 1000 h). No study has been

found which confirms the importance of stoichiometric addition in long term

creep properties. Moreover, this explanation of the good creep properties of

steels with stoichiometric additions of M and X assumes that MX precipitates

form with their final stoichiometry, which has been proved wrong by different

authors.

The non-stoichiometry of MX precipitates in 18/12 austenitic stainless steels has been confirmed

by microprobe analysis (Andrén et al., [14], [15]).

The authors noticed that MX was largely sub-stoichiometric for short ageing

(typically 3 h at 750  C), and contained a large amount of Cr

substituting for

M (Ti,Nb,V...). They proposed the following explanations:

as MX has a lattice parameter larger than that of the austenite,

a flow of vacancies is needed for the growth of MX and stress is generated.

The substitution of M by Cr and the low carbon content both reduce

the lattice parameter.

Moreover, Cr is readily available while M has to diffuse over long distances.

The formation of sub-stoichiometric, carbon depleted MX precipitates is

therefore kinetically advantageous.

In more theoretical terms, this corresponds to two effects.

Capillarity is likely to

modify substantially the local equilibrium as the precipitates are very small.

In fact, the composition changes reported by these authors correlate

with size changes.

The second effect is the modification of local equilibrium to satisfy

simultaneously the flux balance for different solutes.

This effect could affect strongly the composition of MX, since the

diffusivities of the elements involved are very different. It

would similarly correlate with a size change unless the precipitates are only

coarsening.

C), and contained a large amount of Cr

substituting for

M (Ti,Nb,V...). They proposed the following explanations:

as MX has a lattice parameter larger than that of the austenite,

a flow of vacancies is needed for the growth of MX and stress is generated.

The substitution of M by Cr and the low carbon content both reduce

the lattice parameter.

Moreover, Cr is readily available while M has to diffuse over long distances.

The formation of sub-stoichiometric, carbon depleted MX precipitates is

therefore kinetically advantageous.

In more theoretical terms, this corresponds to two effects.

Capillarity is likely to

modify substantially the local equilibrium as the precipitates are very small.

In fact, the composition changes reported by these authors correlate

with size changes.

The second effect is the modification of local equilibrium to satisfy

simultaneously the flux balance for different solutes.

This effect could affect strongly the composition of MX, since the

diffusivities of the elements involved are very different. It

would similarly correlate with a size change unless the precipitates are only

coarsening.

However, stoichiometric carbides still have a lower free energy

and, during further ageing, they grow at the expense of sub-stoichiometric

ones. This is because, according to Andrén et al., the diffusivity of

metallic elements within MX precipitates is so small that these precipitates

can not change composition [14].

Z-Phase is a complex carbonitride which forms in Nb stabilised austenitic stainless steels

containing a relatively high level of nitrogen. It has only recently been

discovered, with its structure being fully determined by Jack and Jack in

1972 [19], and it appears from the most recent reviews (e.g.

[3]) that the conditions of its formation are not very clear,

and even less is its relative stability when compared to other carbonitrides.

The structure of Z-Phase is commonly accepted to be the one described by

Jack and Jack [19]: it has a tetragonal unit cell (space group

P4/nmm), with

a=3.037 Å and c=7.391 Å. The unit cell is obtained by ordering of Cr, Nb

and N atoms, the formula being

Cr2Nb2

N2 per unit cell.

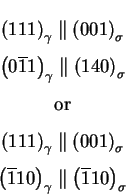

Vodárek [20] reports the following orientation relationship for

Z-phase in a type 316LN:

In contrast to MX precipitates, it seems that Z-Phase dissolves little (if

at all) substitutional elements. Raghavan et al. [21] suggest that

it can dissolve carbon and write CrNb(CN), without giving any

evidence for this. The absence of a CrNbC phase suggests that if carbon can

dissolve in

Z-Phase, it can only do so within limits. Also, when Nb is in sufficient

quantity, both Z phase and NbC are found.

Z-Phase is seldom reported, even in alloys liable to form it on ageing.

This could be due to its composition and its general features of formation

which are not very different from common MX precipitates.

It generally forms on grain-boundaries, very rapidly, but also on

twin boundaries and within the matrix, where it is associated with

dislocations [22]. When it forms, it is usually as a fine dispersion

of particles (see [13],[21], [22]), which makes

it an interesting phase when good creep properties are sought.

The morphology has been reported to be either cuboidal

[22] or rod-like [14].

There is a good agreement that it forms at high temperature:

Raghavan et al. [21]

report its formation during annealing (1 h at 1300 K) of a

18/12 containing 0.3Nb wt% and 0.09N wt%, with an orientation relationship

indicating that these are not residual particles. After ageing 8000 h

at 866 K, it is still the predominant precipitate.

Few

M23C6 and  -phase particles are present.

These authors indicate that a 10 s heat-treatment at 1573 K is sufficient to

dissolve all the Z-phase particles, which is not inconsistent with the work

of Robinson et al. (quoted in [21]) which locates the solvus of

Z-phase to be between 1573K and 1623K in a steel containing larger amounts of

niobium and nitrogen.

-phase particles are present.

These authors indicate that a 10 s heat-treatment at 1573 K is sufficient to

dissolve all the Z-phase particles, which is not inconsistent with the work

of Robinson et al. (quoted in [21]) which locates the solvus of

Z-phase to be between 1573K and 1623K in a steel containing larger amounts of

niobium and nitrogen.

Robinson and Jack [22] report the formation

of Z-Phase in a 20Cr/9Ni

steel containing 0.38N wt% and 0.27Nb wt% between 700 and 1000  C.

At 1000

C.

At 1000  C Z-Phase is the first and only phase formed. It is found

uniformly distributed after 30 min but coarsens rapidly.

At 700

C Z-Phase is the first and only phase formed. It is found

uniformly distributed after 30 min but coarsens rapidly.

At 700  C it starts to precipitate in the matrix after 16 h.

At lower temperatures, Vodárek et al. [23] report a considerable

dimensional stability of Z-phase in a type 316LN, with a mean size

of 6nm after 82 h at 650

C it starts to precipitate in the matrix after 16 h.

At lower temperatures, Vodárek et al. [23] report a considerable

dimensional stability of Z-phase in a type 316LN, with a mean size

of 6nm after 82 h at 650  C and 12nm after 37890 h at the same

temperature.

C and 12nm after 37890 h at the same

temperature.

Thorvaldsson and Dunlop [24], studying the effects

of stabilising

elements in austenitic stainless steels, use a 18/12 steel with 0.4V, 0.13Nb and 0.43N at%.

After 5000 h at 750  C, no Z-Phase has formed, but a (Nb,V)(C,N)

fcc carbonitride forms instead.

Andrén et al. [14], with the same composition,

in very similar conditions, found, on the contrary, that the MX

precipitate had always a stoichiometry not far from M

X0.5, and

contained sensibly as much chromium as Nb+V. However, the characteristic

tetragonality was not observed and the authors suggested that they found a

precursor state of the fully ordered Z-Phase.

C, no Z-Phase has formed, but a (Nb,V)(C,N)

fcc carbonitride forms instead.

Andrén et al. [14], with the same composition,

in very similar conditions, found, on the contrary, that the MX

precipitate had always a stoichiometry not far from M

X0.5, and

contained sensibly as much chromium as Nb+V. However, the characteristic

tetragonality was not observed and the authors suggested that they found a

precursor state of the fully ordered Z-Phase.

It seems quite reasonable to propose that Z-Phase is the stable Nb containing

phase in austenitic stainless steels with high nitrogen: Hughes [13] suggests that it

can be expected in a typical 347 steel as soon as the weight percentage of N

is greater than 0.06 wt%. Knowles [25] find Z-phase in a

20/25 0.41Nb wt% steel with 0.028N wt%, which could indicate that chromium

and/or nickel content play an important role in the solubility of this phase.

The problem arises, in many steels, to know whether NbC or Z-Phase is the more

stable. Very few studies have dealt with additions of Nb, C and N

together in a way that could determine which phase is more stable: often

Nb is in excess and both NbC and CrNbN form. Uno et al. [26]

found that only Z-phase formed in a 18/12

Nb steel with carbon and nitrogen, the niobium content being lower than that

required to combine either all C or all N. This would indicate that Z-phase

is fast enough to form first when competition between NbC and CrNbN is

likely to occur. On the other hand, Knowles [25]

reported Nb(C,N) after 2 h at

850  C in a 20/25 steel, transforming to Z-phase with further ageing.

From the precipitation behaviour of NF709 [5], where

Z is reported after ageing times of 104 h at 750

C in a 20/25 steel, transforming to Z-phase with further ageing.

From the precipitation behaviour of NF709 [5], where

Z is reported after ageing times of 104 h at 750  C,

and C containing phases are

M23C6 and

M6C one can

infer that Z-Phase is more stable than NbC and that the latter will dissolve

for the former if Nb is in too small quantities.

However, Raghavan et al. [21] deduce from a comparison between 347

(18/12 with 0.8Nb and 0.07C wt%) and 347AP

(18/12 with 0.3Nb, 0.09N, 0.009C wt%)

a greater stability of NbC, since Z is found to precipitate from the solid

state but the NbC is found as residual particles. The conclusions of such a

comparison have to be examined carefully as the compositions were different.

C,

and C containing phases are

M23C6 and

M6C one can

infer that Z-Phase is more stable than NbC and that the latter will dissolve

for the former if Nb is in too small quantities.

However, Raghavan et al. [21] deduce from a comparison between 347

(18/12 with 0.8Nb and 0.07C wt%) and 347AP

(18/12 with 0.3Nb, 0.09N, 0.009C wt%)

a greater stability of NbC, since Z is found to precipitate from the solid

state but the NbC is found as residual particles. The conclusions of such a

comparison have to be examined carefully as the compositions were different.

Generally, one can conclude that Z-phase precipitation is not fully understood.

Points of agreement are its stability at high temperature and the features of

its precipitation (fine dispersion), proposed solvus temperatures are different

between the studies, but these differences are consistent with different

compositions.

It is difficult as yet to build a coherent view of the different kinetics

observed. It is not clear whether Z-phase actually forms from MX precipitates

as suggested by the results of Knowles [25] and Andrén

et al. [14], or directly as suggested by Robinson et al.

[22].

These observations could be reconciled if one could prove that the driving

force in a 20Cr 10Ni (Robinson et al.) is significantly different than that of

a 18/12.

The importance of Z-phase in both ferritic and austenitic power

plant steels, renders particularly necessary the assessment of the ternary

system Cr,Nb,N to provide the thermodynamic parameters required for any

prediction.

M23C6 is a more general notation for

Cr23C6, as often,

Ni, Mo and Fe are found to substitute partially for chromium. It is the main

carbide in non-stabilised C containing austenitic stainless steels; nitrogen bearing steels form

Cr2N.

It has a fcc structure (and space group Fm3m) of

lattice parameter varying between

10.57 and 10.68 Å, which is about three times that of the austenite. It is

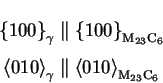

often reported to grow with a cube to cube orientation relationship:

It is most of the time the main carbide found in austenitic stainless steels.

Although it can be only metastable, it is always found in the early stage of

precipitation because it nucleates very easily.

M23C6 is most of the time reported to precipitate on the following nucleation

sites, and in this order: grain boundaries, incoherent and coherent

grain boundaries,

intragranular sites. In Nb stabilised grades, it is sometimes reported

to nucleate on undissolved (that is, during the solution treatment)

niobium carbonitrides.

Generally,

M23C6 only shows

and

and

interface planes. This has been explained by Beckitt and Clarck

(1967, [27]), who showed these planes have the best atomic

correspondence with the austenite.

interface planes. This has been explained by Beckitt and Clarck

(1967, [27]), who showed these planes have the best atomic

correspondence with the austenite.

The precipitation of

M23C6 has been the focus of many investigations,

motivated by its importance in terms of corrosion resistance.

M23C6 on grain

boundaries is often associated with intergranular corrosion. It is found after

very short ageing times (30 mn at 750  C,Lewis et al.,[28]), even

in stabilised steels. It causes the grain boundary to move, and therefore

shows on one side, the new grain boundary, while the other has a serrated

aspect composed by the

C,Lewis et al.,[28]), even

in stabilised steels. It causes the grain boundary to move, and therefore

shows on one side, the new grain boundary, while the other has a serrated

aspect composed by the

interfaces. These precipitates

are usually large. When boron is added, the number density of

M23C6 along the

grain boundaries increases (Tanaka et al.,1997, [29]), with beneficial

effect for the creep rupture strength, as the grain boundary sliding and

surface cracking are reduced.

Other effects of boron in

M23C6 will be dealt with later.

interfaces. These precipitates

are usually large. When boron is added, the number density of

M23C6 along the

grain boundaries increases (Tanaka et al.,1997, [29]), with beneficial

effect for the creep rupture strength, as the grain boundary sliding and

surface cracking are reduced.

Other effects of boron in

M23C6 will be dealt with later.

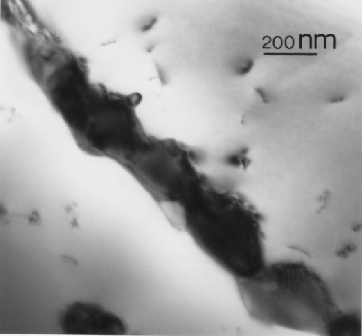

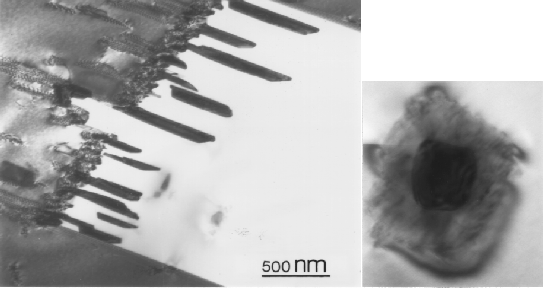

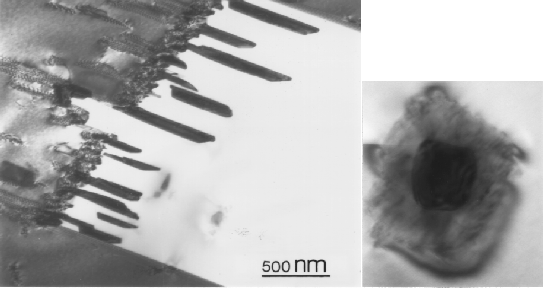

Figure:

M23C6 on grain boundary.

|

On incoherent and coherent twin boundaries,

M23C6 forms long plates parallel

to the twin boundaries. The plates are, as for any form of

M23C6 in austenitic stainless steels,

bounded by

and

and

planes only.

The large faces are

planes only.

The large faces are

planes parallel to the twin

boundaries. Plates are initially growing from the incoherent twin boundary,

but some are found later apparently detached from the boundary. Precipitation

on the coherent boundary occurs more slowly than on incoherent ones.

planes parallel to the twin

boundaries. Plates are initially growing from the incoherent twin boundary,

but some are found later apparently detached from the boundary. Precipitation

on the coherent boundary occurs more slowly than on incoherent ones.

Figure:

Plates of

M23C6 growing from an incoherent twin

boundary (left), and around a Nb(C,N) precipitate (right), work done for

this project.

|

The mechanism of their formation has been subject to

controversy: Beckitt and Clarck (1967, [27]) suggested that

carbides growing on the incoherent twin boundary repels Shockley partial

dislocations in the twin, and these cause nucleation of new plates

in the twin. But detailed observations have lead Singhal and Martin (1967,

[30]) to conclude that stacking fault were first growing in the twin.

M23C6 would then nucleate on the Shockley bounding dislocation and grow

in the stacking fault, possibly helped by an enrichment of this stacking

fault in chromium.

Both fail to explain why these plates most of the time stand

separated from the boundary and from each other (according to these mechanisms,

they should be connected to the incoherent twin boundary by a stacking fault).

Another mechanism has been proposed more recently by Sasmal (1984,

[31]). Noticing that plates do not form away from the boundary or

on coherent twin boundaries if the samples are

directly put at ageing temperature after the solution treatment, Sasmal

suggested that the formation of plates of

M23C6 close but detached from

the incoherent twin boundaries, and on coherent ones, was an effect of

residual stress developed in these regions. One could here argue that stress

only influences the formation: if it favors the formation of

M23C6 plates

parallel to the twin boundaries, there should still be a small percentage of

plates growing in other equivalent directions.

In the austenite grains,

M23C6 precipitates as cuboids or plates. The latter

have the same characteristics as the plates growing from twin boundaries. The

cuboids grow on dislocations until they form a continuous chain sharing

their corner. These chains can form branches, forming secondary stringers of

M23C6.

Beckitt and Clarck (1967, [27])

have proposed satisfactory explanation for the formation of

these secondary stringers: the growth of primary

M23C6 generates dislocations

on which other precipitation can occur. The direction of these secondary

stringers is that expected by the mechanism, that is the direction of usual

edge dislocations in austenite.

Another kind of intragranular precipitation has been reported by Sasmal

(1997, [32]

). Plates of

M23C6 can form around undissolved Nb carbonitrides in Nb

stabilised steels. In this case, the large faces are

and

the edges are

and

the edges are

. The reasons for this change are not clear,

although a contribution of the strain around the undissolved particle is

invoked.

. The reasons for this change are not clear,

although a contribution of the strain around the undissolved particle is

invoked.

M23C6 is, initially, a chromium-iron carbide. However, its

composition is susceptible to large variations. For example, in a typical

2.25Cr1Mo wt% steel,

M23C6 has a composition of about 0.3Fe, 0.38Cr, 0.1Mo,

0.22C mole fraction. While in a typical 304, it is closer to

0.04Fe, 0.65Cr, 0.11Mo, 0.22C.

There are also evidences that, for a given steel composition,

M23C6

composition

undergoes large changes in the early stages of the precipitates.

Lewis and Hattersley [28] quote a study by Philibert et al.

in which the authors propose that

M7C3 forms in the early stages of ageing

in a 18/8 steel, as the Fe/Cr ratio is more consistent with the known

composition of this phase. Similarly, Marshall [1] quotes a study

in which the authors show that up to 40 wt% Fe can be found in

M23C6 in the

early stages of precipitation, but also that the Mo content increases with

time.

It is proposed here that these composition changes can be explained by the

growth mechanism involved. In a multicomponent alloy, the interface has to

move at a rate which is consistent with the flux of each element, in order to

maintain local equilibrium. Therefore, the interfacial compositions are not in

general given by a tie-line passing through the bulk composition, but by an

alternative tie-line which permits the flux-balance (details are out of the

scope of this review, see for example [33] or [34]).

In the same way, on the interstitial lattice, B can

substitute for C; however both in very small quantities.

Boron is of particular interest as it promotes the formation of

intragranular

M23(C,B)6.

There is some controversy about the mechanism involved, but it is possible

that B increases the lattice parameter of

M23C6, therefore reducing the

mismatch with the austenite. The presence of B in

M23C6

has been shown using Atom

Probe Field Ion Microscopy (APFIM, e.g. [35]).

The same is not true for nitrogen. It has long been believed to have a small

solubility in

M23C6 (e.g. [36]). However, recent experimental results

supported by ab initio calculations indicate zero solubility of

nitrogen in

M23C6, the structure of which is destabilised if a small amount of carbon is replaced by nitrogen [8].

Except in the fine intragranular form,

M23C6 precipitation is not

desirable for good creep properties.

It is often associated with intergranular corrosion, as its

formation along the grain boundaries causes a local depletion in chromium and

possibly local loss of

the stainless property (the steel is then said to be sensitised,

i.e. susceptible of intergranular corrosion).

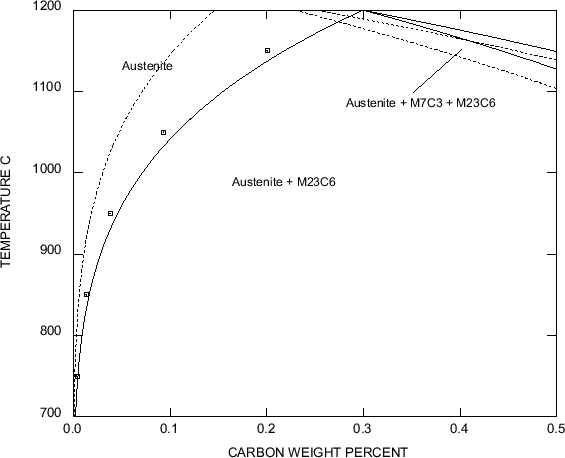

The solubility of carbon in austenite, with regard to

M23C6, has been described

by empirical relationships such as [37]:

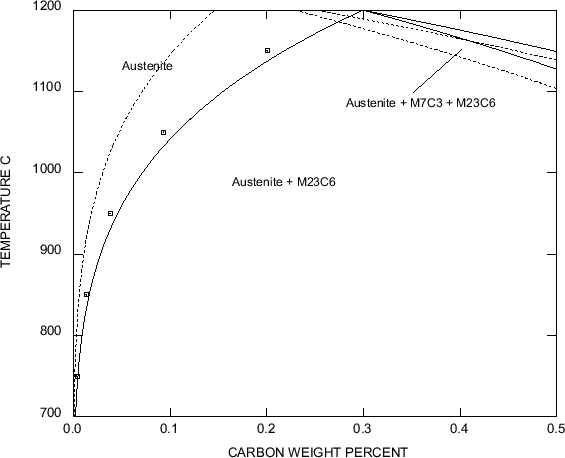

Figure:

Solubility of C in austenite with regard to

M23C6

precipitation. Calculated with MT-DATA (allowing for austenite,

M23C6,

M7C3

and liquid, with elements Fe, Cr, Ni, 0.3Si, 1.0Mn wt%).

Solid lines for 18/12 and dashed lines for 20/25. The squares

correspond to the empirical relationship from

[37]

|

As can be seen in figure 5, this is valid for a typical

18/12

steel, but one should be careful as it is sensibly modified by the

chromium and nickel content. Increasing the chromium content reduces

the solubility of carbon

in austenite. It also increases the kinetics of

M23C6 precipitation, as does

an increase in carbon content: from 0.02 to 0.08C wt%, the nose of the C-curve

is shifted from 100 h to 0.1 h.

M23C6 first precipitates on grain boundaries, then, with increasing

time, on incoherent twin boundaries,

coherent twin boundaries and finally in the matrix on dislocations.

In the matrix, it forms as evenly spaced angular blocks.

At long ageing times, grain boundary carbides can form a completely

interlocked structure.

The kinetics of precipitation is affected by Mo, which stabilises

the carbide and accelerates its formation. On the other hand, nitrogen is

well-known to retard both formation and coarsening rates of

M23C6, and an

often proposed explanation is that nitrogen reduces the

diffusivity of Cr and C in the austenite [4], [9].

However, Degalaix and Foct [38] found that if the carbon content

was higher than 0.08 wt%, increasing the nitrogen content could have the

opposite effect.

More recent investigations indicate that N actually enhances the diffusion of

substitutional elements by increasing the formation of vacancies, but delays

the nucleation of

M23C6, the structure of which is destabilised when carbon is

partially substituted by nitrogen [8].

In a simple type 304 steel ,

M23C6 is often the only carbide found at any ageing

time. Although sometimes

M6C is found (Biss and Sikka, [39]),

it is as a minor phase and no mention is made of an instability of

M23C6

with regard to

M6C. When molybdenum is added (type 316),

M23C6 can

partially transform to

M6C (see further); it is however always reported

that

M23C6 remains the main carbide even after long ageing. In fact,

M23C6

and

M6C also coexists in the X5CrNiMo1713 (17Cr, 13Cr, 5Mo wt%) studied

by Thier et al. [40].

This is not the case when niobium is involved in the formation of

M6C,

which seems then more stable and becomes the dominant carbide at long ageing

times [41].

In stabilised grades, the situation is much more complex: from the

literature found, it is not possible to state clearly whether

M23C6 is

sometimes first formed or always follows MX precipitation, nor which phase is

the more stable on long term ageing.

Thorvaldsson and Dunlop

([24],[42],[43]), studying the effect of

different stabilising elements and

their combinations, found that

M23C6 was more stable than TiC, but less than

NbC. This is consistent with Grot and Spruiell [44], who found

formation of

M23C6 in a type 321 after long term ageing,

and with Kikuchi et al.

[9] for a 20/25. These authors concluded that TiC retards the

precipitation of

M23C6 but does not suppress it.

On the other hand, Bentley and Leitnaker [45],

studying a type 321 steel having been in service for 17 years at 600  C

did not find any

M23C6 and

concluded that TiC was more stable. Lai [46] observed no

M23C6 in a

type 321 used up to rupture (16000-29000 h at 600

C

did not find any

M23C6 and

concluded that TiC was more stable. Lai [46] observed no

M23C6 in a

type 321 used up to rupture (16000-29000 h at 600  C).

C).

Obviously, considerations on the relative stability of the two

phases only make sense if the titanium content is enough to combine all

carbon present, as in the opposite case,

M23C6 forms with the excess carbon.

The studies in which

M23C6 formation appears as an anomaly deal with steels in

which Ti content is higher or equal than that required for full stabilisation.

The agreement is better for NbC, which is more stable than

M23C6. However,

M23C6 can form as a transient phase.

M6C is also known as  -carbide, but will be referred to as

M6C

to avoid confusion with

-carbide, but will be referred to as

M6C

to avoid confusion with  -phase (Laves phase).

It

generally refers to a phase of very variable composition. In most cases, it is

formed only after long ageing times, and therefore is quite little documented.

Moreover, its appearance and disappearance are strongly linked to that of

other constituents and it is difficult to give it any absolute position

in a TTP (Time Temperature Precipitation) diagram.

M6C is a diamond-type fcc carbide whose lattice parameter varies between

10.95 and 11.28 Å. Its space group is Fd3m, which distinguishes it

from

M23C6 and G-phase which both are fcc of similar lattice parameters,

but have a Fm3m space group. The

-phase (Laves phase).

It

generally refers to a phase of very variable composition. In most cases, it is

formed only after long ageing times, and therefore is quite little documented.

Moreover, its appearance and disappearance are strongly linked to that of

other constituents and it is difficult to give it any absolute position

in a TTP (Time Temperature Precipitation) diagram.

M6C is a diamond-type fcc carbide whose lattice parameter varies between

10.95 and 11.28 Å. Its space group is Fd3m, which distinguishes it

from

M23C6 and G-phase which both are fcc of similar lattice parameters,

but have a Fm3m space group. The  -carbide structure is described

by Stadelmaier in [47] for example. This structure encompasses a

wide range of compositions and only the one which are commonly found in creep

resistant austenitic stainless steels will be reviewed here.

-carbide structure is described

by Stadelmaier in [47] for example. This structure encompasses a

wide range of compositions and only the one which are commonly found in creep

resistant austenitic stainless steels will be reviewed here.

M6C composition can be molybdenum-rich

(

(FeCr)21Mo3C6)

or niobium-rich (

Fe3Nb3C). The

molybdenum rich

Fe3Mo3C (a=11.11 Å)

was reported in high Mo steels, but never in austenitic

steels [48]. Instead, a fraction of molybdenum is replaced by iron

or chromium, and the lattice parameter is reduced (a=10.95 Å)

[48]. The composition reported by Brun et al. [49]

in a 316 steel containing Ti shows substantial amounts of Ni also

dissolving in

M6C (see table 4).

Table:

Composition of

M6C as measured by Brun et al. in a

316 steel containing titanium.

| Si at% |

Mo at% |

Ti at% |

Cr at% |

Mn at% |

Fe at% |

Ni at% |

| 4.5 |

6.5 |

0.8 |

30 |

0.5 |

26.7 |

31 |

|

Silicon has

been reported to dissolve in this phase to form

M5SiC, but such a phase is very seldom found.

Other elements which can be included in the general notation

M are Ni, Ti, Co. In NF-709 (a 20/25 Nb stabilised, with 0.17N wt%),

long-term ageing allows formation of

Cr3Ni2SiC; such a composition has

been reported by Williams et al. in a study of irradiated type 316

(1984,[50]) and by Titchmarsh et al. in a similar steel

(1981,[51]), at rather low temperatures (466  C) but not above

670

C) but not above

670  C.

Its formation in such steels is linked with the segregation

effects caused by irradiation, in particular the Si segregation to point

defect sinks.

This particular composition has a lattice parameter of 10.62Å

(JCPDS 17-330),

which makes it extremely similar to

M23C6 from a structural point of view.

Although always referred to as

Cr3Ni2SiC, its actual composition

includes substantial amounts of Mo and Fe (see table 5),

the concentrations of which increase with temperature (Williams,[50]).

Williams therefore proposed the more general formula

(Cr,Mo)3(Ni,Fe)2SiC.

C.

Its formation in such steels is linked with the segregation

effects caused by irradiation, in particular the Si segregation to point

defect sinks.

This particular composition has a lattice parameter of 10.62Å

(JCPDS 17-330),

which makes it extremely similar to

M23C6 from a structural point of view.

Although always referred to as

Cr3Ni2SiC, its actual composition

includes substantial amounts of Mo and Fe (see table 5),

the concentrations of which increase with temperature (Williams,[50]).

Williams therefore proposed the more general formula

(Cr,Mo)3(Ni,Fe)2SiC.

Jargelius-Peterson [52] found a nitrogen rich similar phase (

Cr3Ni2SiN)

after furnace ageing of a 20Cr25Ni5Mo0.2N steel. It is reported after 5h and

3000 h at 850  C, therefore being probably an equilibrium phase. In

agreement with the observation that the Mo content increases with temperature,

the composition found here includes as much as 25 wt% Mo (this is also due

to the larger Mo content of the alloy).

C, therefore being probably an equilibrium phase. In

agreement with the observation that the Mo content increases with temperature,

the composition found here includes as much as 25 wt% Mo (this is also due

to the larger Mo content of the alloy).

In a type 316 steel, the composition of

M6C is close to

(FeCr)21Mo3C6. Weiss and Stickler

[48] proposed that it formed as follows

It is not reported by Minami et al. [41] after 10000 h at 750  C

(instead,

C

(instead,  -phase is found), neither by Lai and Meshkat [53]

after 10000 h at 600 and 650

-phase is found), neither by Lai and Meshkat [53]

after 10000 h at 600 and 650  C, nor by Barcik [54]

for the same time, up

to 900

C, nor by Barcik [54]

for the same time, up

to 900  C. However, it was found by Stoter [55] in specimen

of 316 having been in service at 650

C. However, it was found by Stoter [55] in specimen

of 316 having been in service at 650  C for 28000 and 60000 h, in

very small amounts and always associated with

M23C6.

C for 28000 and 60000 h, in

very small amounts and always associated with

M23C6.

Nitrogen seems to have a large influence on

M6C formation:

Thier et al. [40] did not find this carbide after 1000 h in a type

316 with 0.037N wt%, but found it after only 1 h ageing at 900  C when

the nitrogen content was 0.069 wt%. Gavriljuk and Berns [8]

suggest that the calculations performed by Jargelius-Petterson [56]

raise controversy, as she shows that an increase of nitrogen in a 20Cr,

25Ni, 4.5Mo wt% steel reduces the

driving force for

M6C. However, one must notice that

M6C is quite

poorly described in the SGTE databases, as it only contains information about

the Mo rich carbide, that is to say it describes only one of the possible

compositions of the

C when

the nitrogen content was 0.069 wt%. Gavriljuk and Berns [8]

suggest that the calculations performed by Jargelius-Petterson [56]

raise controversy, as she shows that an increase of nitrogen in a 20Cr,

25Ni, 4.5Mo wt% steel reduces the

driving force for

M6C. However, one must notice that

M6C is quite

poorly described in the SGTE databases, as it only contains information about

the Mo rich carbide, that is to say it describes only one of the possible

compositions of the  -structure. In this regard, it is possible to say

that the

-structure. In this regard, it is possible to say

that the  -structure is in both cases stabilised but with different

compositions. In particular, Jargelius-Petterson [56] reports that

M5SiN is always present and favoured by high nitrogen

contents. It seems therefore that nitrogen generally stabilises the

-structure is in both cases stabilised but with different

compositions. In particular, Jargelius-Petterson [56] reports that

M5SiN is always present and favoured by high nitrogen

contents. It seems therefore that nitrogen generally stabilises the

-structure, but the composition of this phase varies with the alloy.

-structure, but the composition of this phase varies with the alloy.

In type 321 (Ti-stabilised), none of the studies found

report

M6C.

In type 347, on the contrary, the presence of Nb seems to promote

the formation of a niobium rich

M6C. Care should be taken as Powell et al.

[57] have given sensible arguments showing that G-phase

and

M6C had often been mistaken. However, if the structures are very

similar, the composition

should differentiate clearly

Fe3Nb3C or

Cr3Ni2SiC (as in NF709) from

Ni16Nb6Si7.

The experimental methods must be linked with the results of the different

studies. In general, Nb-rich

M6C seems to form only on long-term ageing.

Kikuchi et al. [9] do not report it after 1000 h at 700  C in a

20/25. In a 18/8 steel, it is reported between 600 and 800

C in a

20/25. In a 18/8 steel, it is reported between 600 and 800  C

by Minami et al.

[41] at very long time (

C

by Minami et al.

[41] at very long time ( 50000 h) for 600

50000 h) for 600  C

but faster (

C

but faster ( 2000 h) for 800

2000 h) for 800  C.

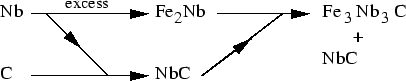

They proposed a sequence illustrated in fig 6.

C.

They proposed a sequence illustrated in fig 6.

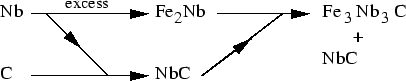

Figure:

Precipitation sequence leading to

M6C when Nb is

in excess, as proposed by Minami et al. in [58]

|

This mechanism implies excess of Nb is present. If Nb is less than that

required for

combination of all carbon, no such phase is observed (Steel Tempaloy A1 in

[41], similar to a 304 with 0.13Nb, 0.06Ti, 0.07C wt%)

In 20/25 alloys, as written above,

M6C and G-phase have probably

been often mistaken (e.g. [59]) in early studies where identification

relied on X-ray or electron diffraction only. It is difficult to conclude which

phase forms preferentially: Ramaswamy et al. [60] report

M6C in a

20/25 with low Si content (0.03 wt%), but other studies report G-phase (Si

content 0.4-0.7 wt%).

When nitrogen is present (in 347 or in 20/25) in sufficient quantities,

Z-phase forms and it is difficult to have an idea of its stability with regard to

M6C.

G-phase, which is considered further, is an alternative Si rich

phase to

Cr3Ni2SiC.

As mentioned above, the composition

Cr3Ni2SiC is very seldom reported in the

literature. Titchmarsh and Williams have reported its formation in

irradiated steel of composition close to that of 316 with addition of 1.8wt% Nb.

They noted [51] and provided evidence [61] that G-phase formed

preferentially only when carbon was not available.

In 20/25-Nb-C steels though, Powell et al. (1984 [62],

1987 [57]) and Ecob et al. (1987 [63]) have found G-phase

and observed that NbC partially transforms to G-phase with time. It seems

reasonable to propose that in 20/25, G-phase is stabilised with regard

to

Cr3Ni2SiC, probably because of the larger Ni content.

However, in NF709 [5]

(composition in table 1),

Cr3Ni2SiC is reported. This is

inconsistent with the

studies quoted above which seem to indicate G-phase as a more stable phase. It

is not clear however whether the presence of carbon or nitrogen

was investigated or

the composition

Cr3Ni2SiC assumed. Investigations of the exact nature of this

precipitate are required to determine whether it is a nitride or a carbide.

A nitride would be expected as it would not be incoherent with the former

observations that G-phase is more stable than

Cr3Ni2SiC and that the  -structure

is stabilised by nitrogen.

-structure

is stabilised by nitrogen.

Intermetallic phases

Sigma phase is a well-known intermetallic phase which forms in the

Fe-Cr system, with a composition FeCr. In highly alloyed steels, its

composition is variable. Its precipitation is associated with embrittlement. In

creep resistant steels, it has a detrimental effect on creep properties when

precipitated on grain boundaries, but little effect when it precipitates

intragranularly.

Sigma has a tetragonal unit cell (space group P42/mnm) with a=8.80 Å

and c=4.54 Å (FeCr). This unit cell contains 30 atoms.

Reported orientation relationships are [4]:

The composition varies quite widely and it is difficult to give a formula.

For example, Jargelius-Petterson [56]

reports the following range of composition for

sigma in a 20/25 with Mo content varying between 4.5 and 6.0 wt%:

| |

Si |

Cr |

Mn |

Fe |

Ni |

Mo |

| wt% |

0-1 |

27-32 |

1-9 |

35-43 |

8-15 |

10-16 |

for a type 316 [36], a typical composition is (other elements not given):

An in-depth review of  -phase precipitation in Cr-Ni austenitic steels

has been done by Barcik [64].

Sigma phase precipitates first on triple points then on grain faces. After

long term ageing at high temperature, it also forms on incoherent twin

boundaries and intragranular inclusions.

The mechanism of nucleation is still a matter of controversy, particularly

on the role of

-phase precipitation in Cr-Ni austenitic steels

has been done by Barcik [64].

Sigma phase precipitates first on triple points then on grain faces. After

long term ageing at high temperature, it also forms on incoherent twin

boundaries and intragranular inclusions.

The mechanism of nucleation is still a matter of controversy, particularly

on the role of  -ferrite and

M23C6 in the nucleation process.

Studies have reported its formation

associated with the dissolution of

M23C6, but also independently [4].

It is found in most of the grades of austenitic stainless steels: type 304, 316 (Mo), 321 (Ti stabilised) and 347 (Nb stabilised) (see for example [41]).

However, it forms after different times. The 25Cr-20Ni steels can exhibit as

much as 20 wt% of

-ferrite and

M23C6 in the nucleation process.

Studies have reported its formation

associated with the dissolution of

M23C6, but also independently [4].

It is found in most of the grades of austenitic stainless steels: type 304, 316 (Mo), 321 (Ti stabilised) and 347 (Nb stabilised) (see for example [41]).

However, it forms after different times. The 25Cr-20Ni steels can exhibit as

much as 20 wt% of  -phase.

-phase.

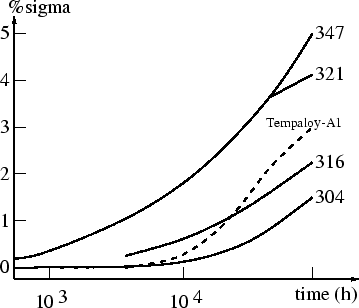

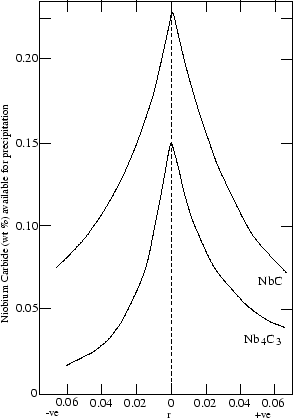

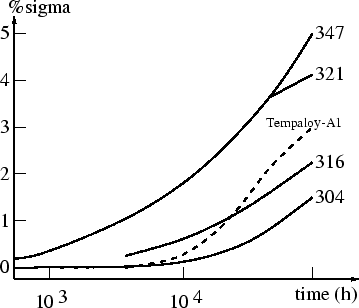

Figure:

Precipitation of sigma in different grades of austenitic stainless steels.

Tempaloy-A1 is an 18/10 with a Nb/C ratio of 1.86, whereas the 347 has a ratio

of 17.40. The percentage is the area etched by KOH. After [41]

|

In stabilised grades, its formation is

faster than in other grades: Minami et al. report precipitation of  after

1000 h at 700

after

1000 h at 700  C in 347 and 321

(347 precipitating

C in 347 and 321

(347 precipitating  slightly faster

than 321). In 304, 316 and Tempaloy-A1,

slightly faster

than 321). In 304, 316 and Tempaloy-A1,  phase is found in significant

quantities only after 10000 h (fig 7).

It is worth noting that Tempaloy-A1 is Nb

stabilised, but with a Nb/C ratio of 1.86, while this ratio is

17.40 in the 347.

This correlates well with the fact that

phase is found in significant

quantities only after 10000 h (fig 7).

It is worth noting that Tempaloy-A1 is Nb

stabilised, but with a Nb/C ratio of 1.86, while this ratio is

17.40 in the 347.

This correlates well with the fact that  forms when the carbon content

falls below a critical value when the chromium equivalent is higher than 18wt%.

In the 347, almost all the carbon is rapidly precipitated as NbC, while the low

Nb content of Tempaloy-A1 leaves some carbon in solution.

The different trend for 321 could be linked to the instability of TiC with

regard to

M23C6. The precipitation of

M23C6 lowers both the carbon and the

chromium content.

The results of Grot and Spruiell [44] show on the contrary no sigma

phase forming up to 2000 h in a type 321.

forms when the carbon content

falls below a critical value when the chromium equivalent is higher than 18wt%.

In the 347, almost all the carbon is rapidly precipitated as NbC, while the low

Nb content of Tempaloy-A1 leaves some carbon in solution.

The different trend for 321 could be linked to the instability of TiC with

regard to

M23C6. The precipitation of

M23C6 lowers both the carbon and the

chromium content.

The results of Grot and Spruiell [44] show on the contrary no sigma

phase forming up to 2000 h in a type 321.

-phase is also found in 20/25 (fig 8).

Different factors affect the formation of sigma phase. Elements like Cr, Nb, Ti

or Mo are known to promote

-phase is also found in 20/25 (fig 8).

Different factors affect the formation of sigma phase. Elements like Cr, Nb, Ti

or Mo are known to promote  formation. Silicon promotes and accelerates

its formation. In general, the formation of sigma in austenite is about 100

times slower than in ferrite. Consequently, the presence of

formation. Silicon promotes and accelerates

its formation. In general, the formation of sigma in austenite is about 100

times slower than in ferrite. Consequently, the presence of  -ferrite

accelerates sigma precipitation. [64]

-ferrite

accelerates sigma precipitation. [64]

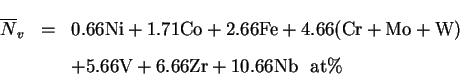

A method has been developed by Woodyatt et al. [4] to estimate

the  -forming

tendency of an alloy, based on the electron vacancy number

-forming

tendency of an alloy, based on the electron vacancy number

:

:

If

is higher than 2.52, the alloy should form

is higher than 2.52, the alloy should form  .

.

Laves phase is found in various grades of austenitic stainless steels. It is

often a minor constituent. It precipitates intragranularly in the form of

equiaxed particles, occasionally on grain boundaries [48]. Whether

Laves phase has a detrimental effect or not on creep properties is still

discussed. In niobium stabilised steels however, it is likely that Laves phase

are detrimental because they allow formation of

M6C (see below).

Laves phase is a

hexagonal phase of space group P63/mmc, with a=4.73 Å and

c=7.72 Å. The main factor determining its formation being the relative atomic

size of the constituent atoms, the ranges of composition are quite

small.

Jargelius-Petterson [56] measured the following composition

for Laves phase in a 20/25 with 5Mo wt%:

After 10 min at 850  C C |

| |

Fe |

Mo |

Cr |

Ni |

Mn |

Si |

| wt% |

|

|

|

|

|

|

After 3000 h at 850  C C |

| wt% |

|

|

|

|

|

|

This shows that Laves phase probably does not form at its exact equilibrium

composition. In stabilised grades,

Fe2Nb or

Fe2Ti (more seldom) can form.

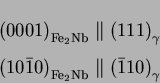

Denham et al. (1969, [65] proposed for

Fe2Nb the following orientation relationships:

In type 304, Laves phase is not found, due to the absence of Mo, Nb or Ti. In

type 316, which contains typically 2-2.5Mo wt%, it is found after relatively

long ageing times: Minami et al. [41]

report its formation after a minimum of 1000 h,

between 625 and 800  C.

The

experimental results of Lai [66] are in agreement with the

dissolution of

Fe2Mo above 800

C.

The

experimental results of Lai [66] are in agreement with the

dissolution of

Fe2Mo above 800  C. Coherently,

White and Le May [67] do not report any Laves phase precipitation

between 640 and 800

C. Coherently,

White and Le May [67] do not report any Laves phase precipitation

between 640 and 800  C for ageing times up to 900 h. Weiss and Stickler

[48] report a slightly higher maximum temperature for Laves

precipitation in type 316 as they found it up to 815

C for ageing times up to 900 h. Weiss and Stickler

[48] report a slightly higher maximum temperature for Laves

precipitation in type 316 as they found it up to 815  C. Its formation

interacts in a competitive way with that of

C. Its formation

interacts in a competitive way with that of  and

and  phases.

For example, the presence of

phases.

For example, the presence of  -ferrite delays its formation because it

enhances that of

-ferrite delays its formation because it

enhances that of  and

and  phases.

phases.

In titanium stabilised grades, the formation of

Fe2Ti

is never reported in compositions similar to that of a 321 steel.

Minami et al. do not report it for ageing times up to

50000 h between 600 and 750  C, in a type 321.

However, it is found by Beattie and Hagel [68] in a A286 type alloy, containing 16Cr, 26Ni and 1.8Ti wt%, after 1000 h at 815

C, in a type 321.

However, it is found by Beattie and Hagel [68] in a A286 type alloy, containing 16Cr, 26Ni and 1.8Ti wt%, after 1000 h at 815  C.

This is directly related to the large amount of Ti used in such steels

compared to a typical 321.

C.

This is directly related to the large amount of Ti used in such steels

compared to a typical 321.

In niobium stabilised steels,

Fe2Nb is frequently

reported after long ageing times, but as a transient phase which disappear for

Fe3Nb3C.

It is reported to form in a type 347 with

0.87Nb and 0.05C wt%, after 1000 h between 650 and 800  C, and

disappear after 5000-10000 h [41]. However, its formation is

dependent on the availability of niobium. In the same study, the Tempaloy-A1

(18/10 with 0.13Nb for 0.07C wt%) do not precipitate Laves phase after

ageing treatments up to 25000 h. Instead, only NbC is found (see figure

6). The same results are reported by Raghavan et al.

[21], who found NbC and Laves phase in a type 347 with 0.8Nb and

0.07C wt% (8000 h at

C, and

disappear after 5000-10000 h [41]. However, its formation is

dependent on the availability of niobium. In the same study, the Tempaloy-A1

(18/10 with 0.13Nb for 0.07C wt%) do not precipitate Laves phase after

ageing treatments up to 25000 h. Instead, only NbC is found (see figure

6). The same results are reported by Raghavan et al.

[21], who found NbC and Laves phase in a type 347 with 0.8Nb and

0.07C wt% (8000 h at  600

600  C), but only Z-phase in a

modified 347 with

0.3Nb and 0.09N wt%. It is therefore probable that both NbC and Z-phase

are more stable than

Fe2Nb.

C), but only Z-phase in a

modified 347 with

0.3Nb and 0.09N wt%. It is therefore probable that both NbC and Z-phase

are more stable than

Fe2Nb.

phase is most of the time a minor intermetallic phase. It is mainly

found in type 316 above 750

phase is most of the time a minor intermetallic phase. It is mainly

found in type 316 above 750  C

C

phase is a bcc (body-centered cubic)

phase of space group

phase is a bcc (body-centered cubic)

phase of space group

. The unit cell

contains 58 atoms and has a lattice parameter varying between 8.807 and

8.878 Å.

A typical composition is

Fe36Cr12Mo10

but the phase has a high tolerance for metal interchanges. The structure has

large holes which allow presence of carbon, sometimes making this phase

better described as a

M18C carbide.

It nucleates on

grain boundaries, incoherent twin boundaries but also intragranularly on

dislocations.

. The unit cell

contains 58 atoms and has a lattice parameter varying between 8.807 and

8.878 Å.

A typical composition is

Fe36Cr12Mo10

but the phase has a high tolerance for metal interchanges. The structure has

large holes which allow presence of carbon, sometimes making this phase

better described as a

M18C carbide.

It nucleates on

grain boundaries, incoherent twin boundaries but also intragranularly on

dislocations.

Although it is sometimes (but seldom) present in very small quantities in 321

[44],  phase is only a significant phase in type 316, when

the ageing temperature is high enough. For example,

it is reported by Minami et al. for times up to 25000 h and temperatures

between 700 and 850

phase is only a significant phase in type 316, when

the ageing temperature is high enough. For example,

it is reported by Minami et al. for times up to 25000 h and temperatures

between 700 and 850  C, and by Lai et al., as being the main phase with

C, and by Lai et al., as being the main phase with

between 715-850

between 715-850  C for times up to 5000 h, but not by Stoter

[55] after 28000 and 60000 h at 650

C for times up to 5000 h, but not by Stoter

[55] after 28000 and 60000 h at 650  C.

C.

G-Phase is a silicide forming in austenitic stainless steels stabilised with Ti or Nb.

It has been first reported by Beattie and Versnyder in 1956, in a A286 type

steel, that is a precipitation-hardening 26Ni-15Cr with variable

(0 to 2.3wt %) Ti and Al contents.

It has long been believed to form only under irradiation in

steels of the 300 series and in 20/25 steels.

However, Powell et al. showed, in 1985 [57] that it formed under

normal ageing in 20/25 Nb stabilised alloys, in the temperature range

500-850  C, and suggested that it had been identified as

M6C in earlier

studies of the same steel.

C, and suggested that it had been identified as

M6C in earlier

studies of the same steel.

G-Phase has a general formula

A16D6C7 where A and D are transition

elements, and C a group IV element [63]. A is usually nickel, D

niobium (ref [57],[62],[63]) or titanium

[46].

Ecob et al. [63] mentioned the possibility of substitution, in

small quantities, of D (ie Nb or Ti) by Fe or Cr, and Powell et al.

[57] measured the following composition:

Table:

Composition of G-Phase measured in [57]

| |

Ni |

Nb |

Si |

Fe |

Cr |

| Wt% |

51 |

29 |

14 |

4.5 |

1.5 |

|

Lai found a titanium containing G-phase in a type 321 steel, and gives

a composition sensibly richer in nickel (table 7).

Table:

Composition of G-Phase measured in [46]

| |

Ni |

Ti |

Si |

Fe |

Cr |

| Wt% |

63.3 |

20.9 |

12.2 |

3.47 |

0.13 |

|

Note that none of these compositions clearly shows substitution of D when

trying to match the stoichiometric formula.

G-Phase has a fcc structure with a lattice parameter of

11.2 Å, this

corresponds to a content of 116 atoms per unit cell. The space group for

this structure is Fm3m.

It is remarkable that the lattice parameter seems to be the same for

Ni16Nb6Si7

(see [57],[62]) and

Ni16Ti6Si7 (see

[46],[68]). In a earlier study, Sumerling et al.

[59], studying a 20/25 Nb stabilised steel, found a lattice

parameter of  Å for a phase they identified as

M6C .

Å for a phase they identified as

M6C .

As mentioned before, Powell et al. have suggested that G-Phase was

identified as

M6C in early works on 20/25 Nb steels, because of close

compositions and structures. A detailed investigation of the structure

is sufficient to solve the problem (Ecob et al.,[63]), but additional

evidence has been sought by the use of EELS (Electron Energy Loss

Spectroscopy) (as in [57]) or a wavelength-dispersive crystal

spectrometer in SEM (as in [46]), both techniques making possible

quantitative measurements of light elements (C,N). These studies have confirmed

the absence of interstitial elements in G-Phase.

The general features of G-Phase formation are:

- It forms very predominantly on grain-boundaries (from where its name)

- It is now clear that it forms in 20/25 Nb stabilised steels and to an

extent which depends on the Si content.

- It has also been reported in a type 321 steel, but other results are

contradictory.

In one of the first studies on G-Phase

(Beattie and Hagel,[68])

the Ti rich G-phase is reported in a A286 type steel. It is not clear in what

conditions of temperature and time it forms, as it was often found to resist

the solution-treatment. However, G-Phase was not found in the alloy

containing only 0.01Si wt%, but formed at higher contents, and the volume

increased with the Si content. Adding 2 wt% of Al suppressed the formation

of G-Phase. This work also included a

steel in which the Ti content is more similar to that used in the 300 series, and

no G-phase was found.

The only report found of Ti rich G-phase in type 321

has been quoted above (Lai, [46]). Three out of seven type 321 steels

show G-phase after 16000h and 50000h at 600  C. The common factors between

the three type 321 steels which are found to form Ti rich G-phase in this study

are their small grain sizes and an excess of Ti with regard to the amount of

carbon present. However, in similar conditions, other studies (Minami et al.,

[41]; Bentley et al. [45]) do not report G-phase.

C. The common factors between

the three type 321 steels which are found to form Ti rich G-phase in this study

are their small grain sizes and an excess of Ti with regard to the amount of

carbon present. However, in similar conditions, other studies (Minami et al.,

[41]; Bentley et al. [45]) do not report G-phase.

In 20/25-Nb-C stabilised steels, it is now clear that G-Phase can

form (see [57], [63], [62]) and, following the

suggestion of Powell et al., the works of Sumerling et al. and Dewey et al.

may be regarded as other evidences for G-Phase formation if one accepts

that

M6C must be read as G-Phase. In [59], in particular, the

authors measured a lattice parameter of  Å which

is much closer to the G-Phase parameter.

Å which

is much closer to the G-Phase parameter.

Figure:

TTP diagram from Powell et al. [57]

|

Powell et al. summarised their work in a TTP (Time Temperature

Precipitation) diagram shown in fig 8.

In their alloy (0.68Nb, 0.037C, 0.61Si wt%), G-Phase forms between

500 and 850  C, first on residual grain boundary particles of NbC, and

only after very long ageing on NbC particles in the matrix. The authors

propose that this is due to the easier diffusion of required elements in

the grain boundaries.

C, first on residual grain boundary particles of NbC, and

only after very long ageing on NbC particles in the matrix. The authors

propose that this is due to the easier diffusion of required elements in

the grain boundaries.

Ecob et al. [63], comparing the occurrence of G-Phase

in similar 20/25-Nb stabilised steels, noticed that alloys apparently similar

in composition exhibited different relative stabilities of NbC with regard to

G-Phase. They found that

an increase in the oxygen content led to a greater instability of NbC with

regard to G-Phase, and proposed that oxygen and silicon are involved in

a co-segregation process, a greater amount of oxygen segregating around NbC

leading to a greater segregation of Si in the same way. The silicon rich

region is more favorable to G-Phase formation.

In 20/25-Nb-N steels however, as it has been discussed in the section

regarding

M6C, it seems that

Cr3Ni2SiN forms preferentially to G-phase. No

results could be found that support this hypothesis.

In common 18/12-Nb steels, G-phase seems to be found only under

irradiation (Titchmarsh and Williams [51], Williams [50]).

Increasing the Si content to 6 wt% resulted in the formation during

furnace ageing of Nb G-phase, although provided that carbon was not available

to form

Cr3Ni2SiC. However, no study has been found which report niobium

G-phase in ordinary 18/12 steels.

Precipitates such as

Ni3Ti,

Ni3(Ti,Al), are only found in a particular class of

austenitic stainless steels: the precipitation hardening ones. A typical steel in

this category is A286, a 15Cr-25Ni-Al-Ti steel. They contain titanium and

aluminium in quantities substantially larger than the 300 series and related

compositions, to form

or other Ni, Ti, Al precipitates, as summarised in figure

9.

or other Ni, Ti, Al precipitates, as summarised in figure

9.

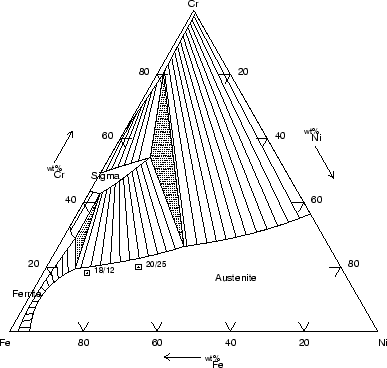

Figure:

Effect of aluminium and titanium on the equilibrium

phases present at 800  C in 15Cr-25Ni austenitic steels, from [69]

C in 15Cr-25Ni austenitic steels, from [69]

|

However, there are very few studies in which the creep properties of these steels

are given attention, and long term informations are not available (see for

example [70]). For this reason and because the precipitation in these

steels has been reviewed in [71], [69], it has been decided not