Iron-cobalt alloys are used as soft-magnetic materials in circumstances where a high magnetic saturation is important. There is confusion in the literature about the cause of an observed discontinuity in the variation of strength and coercivity as a function of the temperature at which cold-rolled Fe-Co alloys are annealed. It is shown here using calculations based on published data, that the variety of observations can be reconciled on the basis of grain growth rather than the extent of recrystallisation.

FeCo alloys have for some time been the materials of choice for applications where a high magnetic saturation is a prime design parameter, particularly in the aerospace industries where volume and mass need to be minimised.

There has been a resurgance of interest in these alloys, particularly with

the development of very strong variants [1,2]. The interest is driven

primarily by the need for a soft-magnetic material for the construction of

electric motors which can be embedded in hot regions of aircraft engines

[3,4,5]. In such applications, the alloys are required in a laminated

form in order to reduce eddy current losses. The production process therefore

involves cold-rolling, followed by annealing in dry H2 at temperatures in

the range 720 and 850 ![]() C.

C.

In the following, all compositions indicate weight percent added to an equiatomic FeCo alloy (or near equiatomic as most publications do not specify).

There is disagreement in the literature over the conditions required to

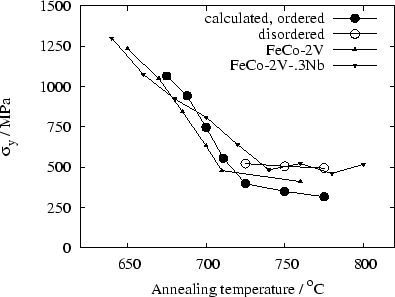

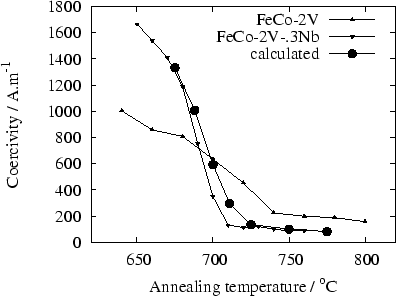

achieve full recrystallisation. Thornburg [1] studied a FeCo-2%V alloy

cold rolled to 90% reduction in thickness, then annealed 2 h at temperatures in

the range 640 to 760 ![]() C followed by air cooling to room temperature. It was

found that the strength and coercivity decreased sharply as the

annealing temperature was increased, until about 710

C followed by air cooling to room temperature. It was

found that the strength and coercivity decreased sharply as the

annealing temperature was increased, until about 710 ![]() C, beyond which the

properties changed little (see FeCo-2V in figure 1).

C, beyond which the

properties changed little (see FeCo-2V in figure 1).

Hailer [6] repeated the experiments on FeCo-2V-0.3Nb and obtained similar

results: both strength and coercivity decreased sharply until an annealing

temperature of about 730 ![]() C (figure 1).

In both cases, the authors attributed the observations

to incomplete recrystallisation below these temperatures. Unfortunately, neither

measured the grain size as a function of annealing temperature, as a matter of

fact, neither undertook detailed metallography of the material.

C (figure 1).

In both cases, the authors attributed the observations

to incomplete recrystallisation below these temperatures. Unfortunately, neither

measured the grain size as a function of annealing temperature, as a matter of

fact, neither undertook detailed metallography of the material.

Although seemingly reasonable, the interpretation in terms of the extent of

recrystallisation contradicts a number of independent results. For example,

Buckley [7] observed full recrystallisation of cold-rolled

FeCo-0.4Cr at low temperatures (250-475 ![]() C) and suggested that, in this

range of temperatures, recrystallisation was enhanced by the ordering reaction

typical in FeCo alloys.

Davies and Stoloff also reported recrystallisation of FeCo-2V after only 1 h at

675

C) and suggested that, in this

range of temperatures, recrystallisation was enhanced by the ordering reaction

typical in FeCo alloys.

Davies and Stoloff also reported recrystallisation of FeCo-2V after only 1 h at

675 ![]() C; more recently, Duckham et al. [2] obtained recrystallised

structures after 1 h at 650

C; more recently, Duckham et al. [2] obtained recrystallised

structures after 1 h at 650 ![]() C in FeCo-2V-0.3Nb. Unfortunately, none of

these authors reported the variations of strength or coercivity with annealing

temperature, at least not over a range of temperature large enough for

comparison with Thornburg [1] or Hailer [6].

C in FeCo-2V-0.3Nb. Unfortunately, none of

these authors reported the variations of strength or coercivity with annealing

temperature, at least not over a range of temperature large enough for

comparison with Thornburg [1] or Hailer [6].

In the present work, published data for grain growth, coercivity and strength are used to solve the apparent inconsistencies.

An exhaustive review of studies undertaken

on magnetic and mechanical properties of FeCo based alloys has recently been

completed [8]. By gathering a vast amount of published data, it was shown

that the coercivity of most existing FeCo based alloys (FeCo, FeCo-V, FeCo-V-Nb,

FeCo-Ta), in the annealed condition, is dictated essentially by the grain size,

and that a unique line can be used to approximate the dependence:

A number of studies have reported the influence of grain size

on strength (for example, [9,10,11,12]) and interpreted the results in

terms of a Hall-Petch relationship:

| (2) |

Although the parameters reported in these publications seem to differ significantly, it can be shown [8] that they are roughly equivalent over the range of grain sizes usually observed. These parameters are reported in .

|

In the analysis that follows, the parameters reported by Jordan and Stoloff

[12] are used, so that:

Few studies have looked at grain growth in FeCo based alloys. It appears that only Davies and Stoloff [14] provide the data required to understand the impact of heat-treatment on strength and coercivity. However, neither Thornburg nor Hailer seem to have been aware of this study.

Davies and Stoloff [14] studied the kinetics of grain growth at

temperatures ranging from 675 to 775 ![]() C and reported significantly different

behaviour above and below the critical temperature for ordering

C and reported significantly different

behaviour above and below the critical temperature for ordering

![]() . In particular, while grain growth was reasonably fast above Tc, it

was found to be much slower below this temperature. Table

2 lists the grain sizes after 1 h annealing.

. In particular, while grain growth was reasonably fast above Tc, it

was found to be much slower below this temperature. Table

2 lists the grain sizes after 1 h annealing.

For this reason, the strength of FeCo alloys was at first calculated using equation 3 for all annealing temperatures, and then, using equation 3 for annealing temperatures below Tc and equation 4 for annealing temperatures above Tc. The results are shown in figures 1 and 2.

|

|

The agreement between the calculated and measured values is surprisingly good, as it must be remembered that equations 2, 3 and 4 have been derived using different experimental data, obtained using annealing temperatures greater than Tc.

The important result is that all the observed variations can be explained quantitatively on the basis of grain size variations alone, rather than by postulating variations in the extent of recrystallisation.

The sharp change in strength and coercivity versus annealing temperature around

720 ![]() C has in the past been attributed to incomplete/complete

recrystallisation [1,6]. The present analysis shows that the changes

are fully understood in terms of the grain size of fully recrystallised

samples. The reason for the discontinuity in the property versus annealing

temperature curves is simply that rate of grain growth changes sharply around

critical ordering temperature Tc.

C has in the past been attributed to incomplete/complete

recrystallisation [1,6]. The present analysis shows that the changes

are fully understood in terms of the grain size of fully recrystallised

samples. The reason for the discontinuity in the property versus annealing

temperature curves is simply that rate of grain growth changes sharply around

critical ordering temperature Tc.

The author is grateful to Rolls-Royce, in particular S. W. Hill, for funding the project this work is part of, and to Pr. H. K. D. H. Bhadeshia for useful discussion.

This document was generated using the LaTeX2HTML translator Version 2002 (1.62)

Copyright © 1993, 1994, 1995, 1996,

Nikos Drakos,

Computer Based Learning Unit, University of Leeds.

Copyright © 1997, 1998, 1999,

Ross Moore,

Mathematics Department, Macquarie University, Sydney.

The command line arguments were:

latex2html -split 1 -title 'Evolution of strength and coercivity during annealing of FeCo based alloy' -white -noparbox_images -math_parsing -notop_navigation -nonavigation -noreuse -dir ./ index.tex

The translation was initiated by on 2004-05-17