![[Queen Mary University of London]](https://www.phase-trans.msm.cam.ac.uk/QMUL.png)

Continuously cooled hypoeutectoid steel

H. K. D. H. Bhadeshia

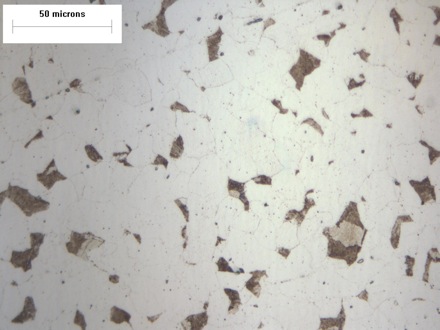

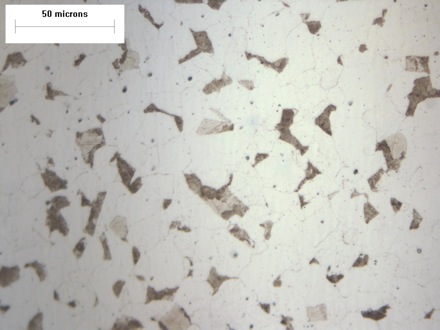

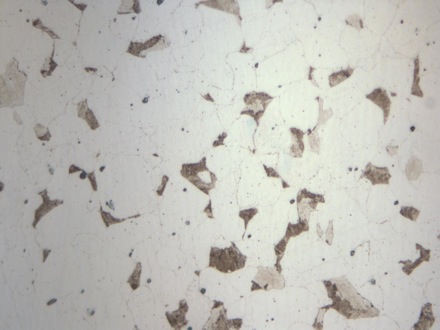

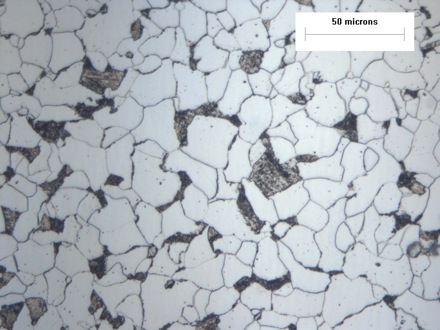

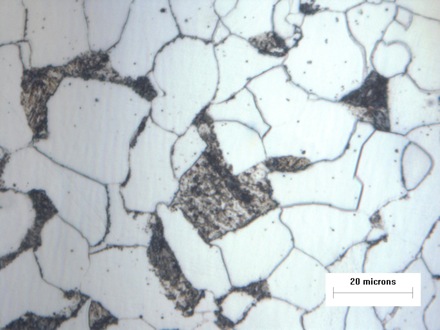

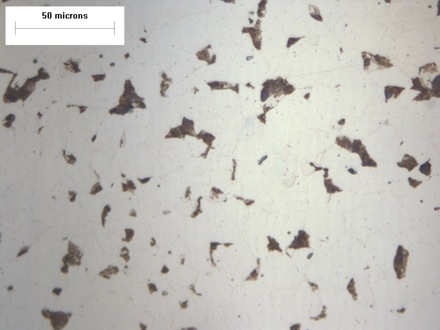

The vast majority of the 1.3 billion tonnes of steel proudced annually have a microstructure which is a mixture of allotriomorphic ferrite and pearlite. The pearlite is the last phase to form during transformation of the austenite remaining after the formation of allotriomorphic ferrite. By adjusting the hardneability or increasing the cooling rate, this residual austenite can transform into a mixture of phases including fine pearlite, bainite and martensite. This can be deduced using optical microscopy as described below, and confirmed using scanning electron microscopy.

The micrographs were taken by Stephen Davidson.

Note that micron should be taken to mean micrometres.

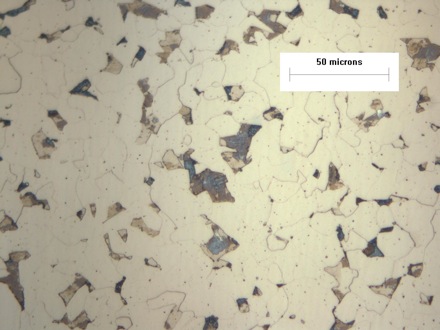

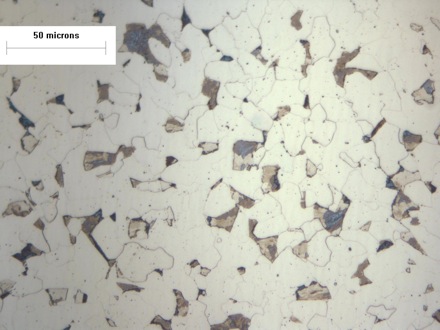

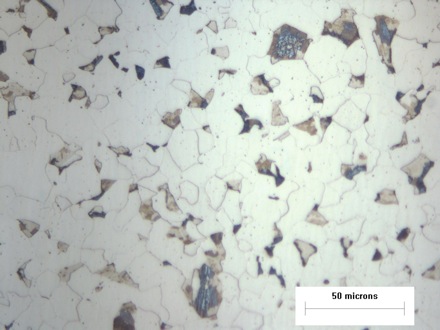

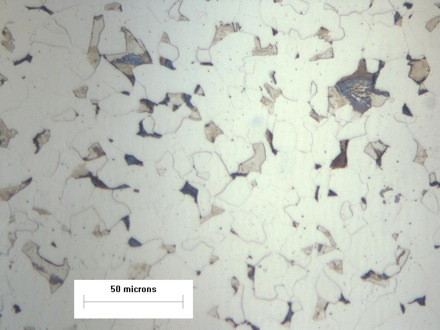

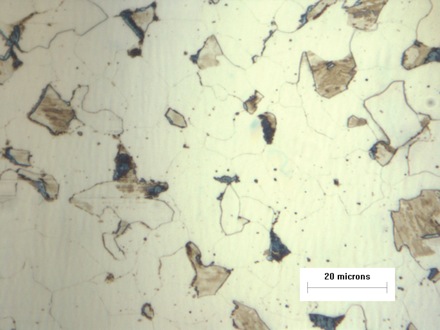

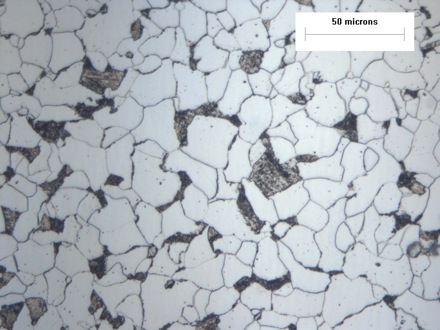

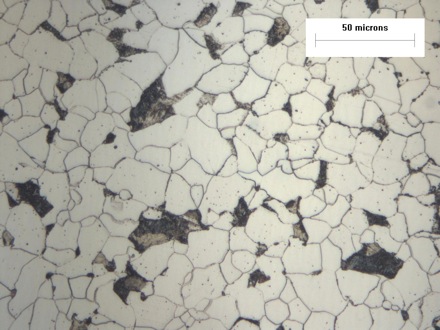

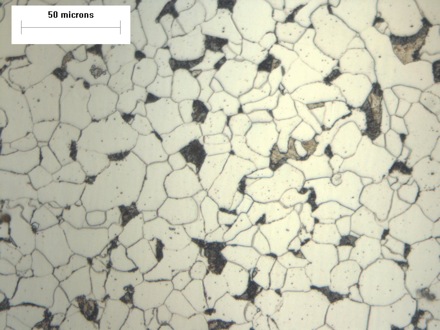

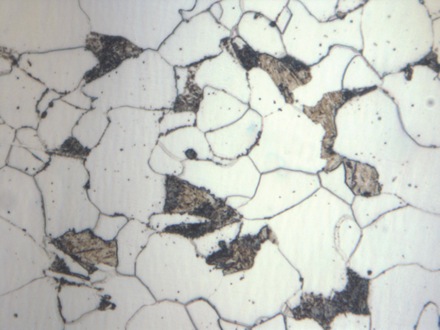

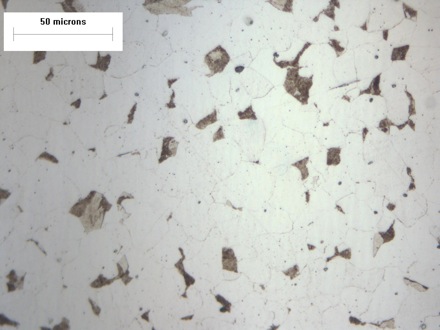

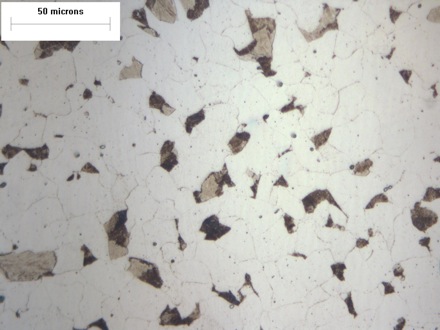

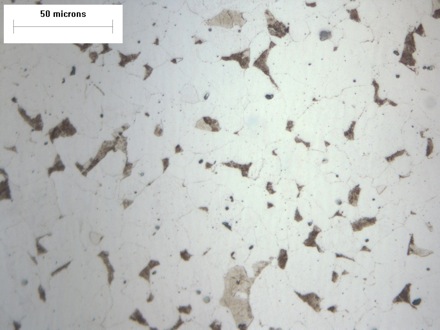

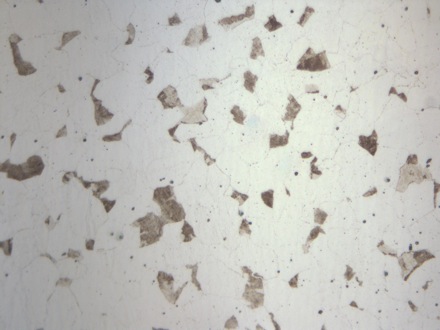

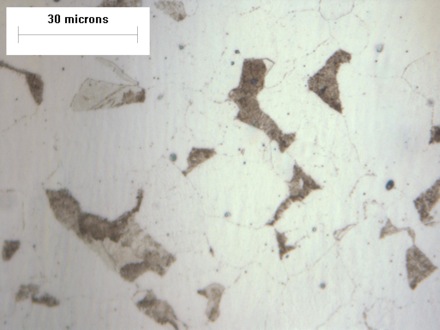

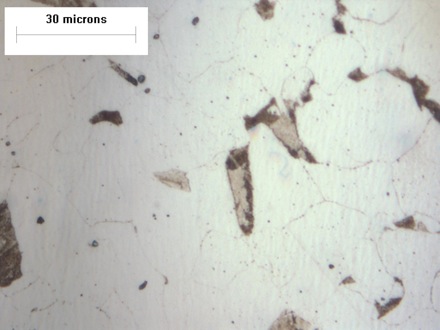

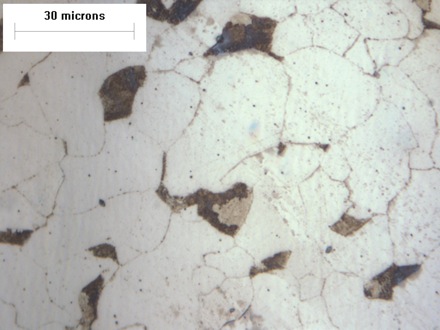

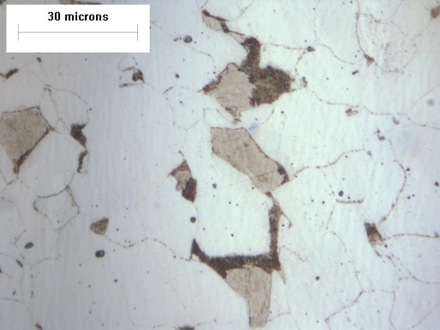

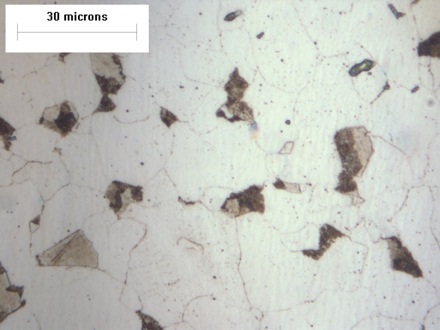

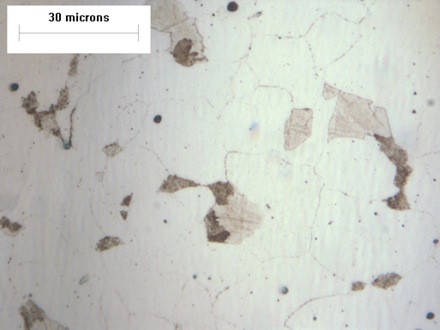

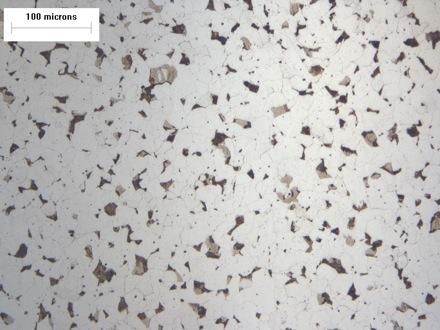

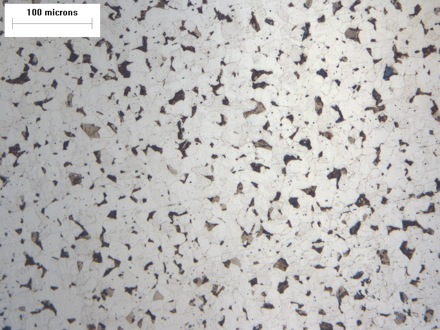

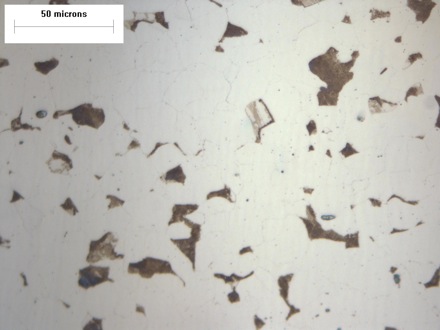

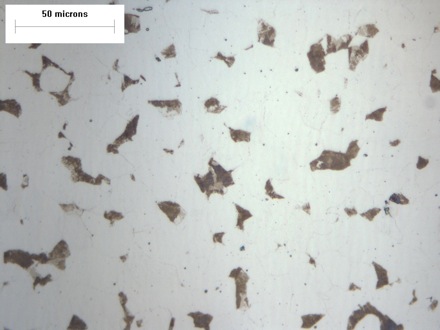

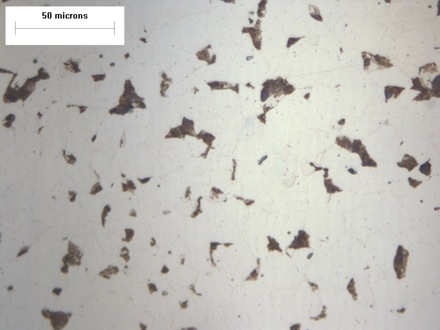

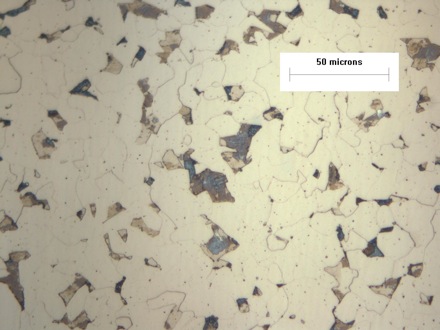

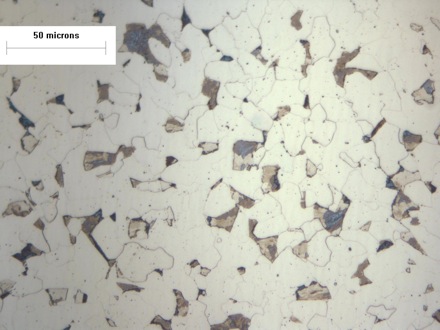

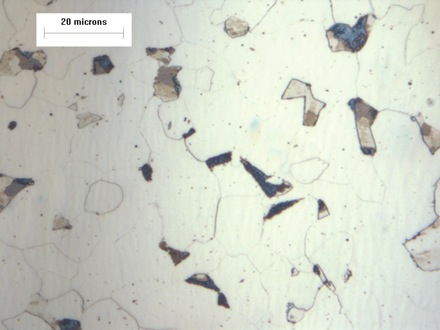

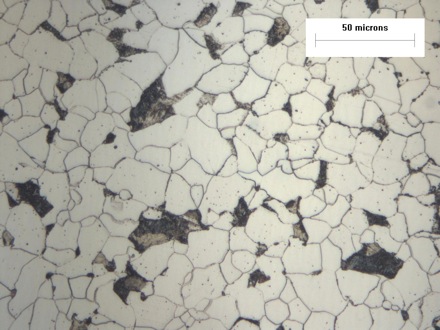

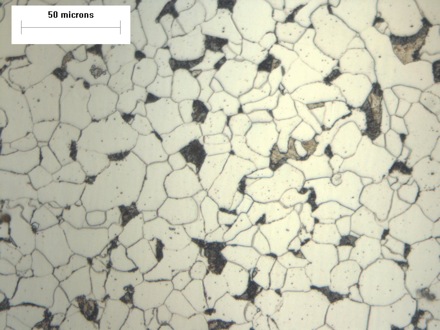

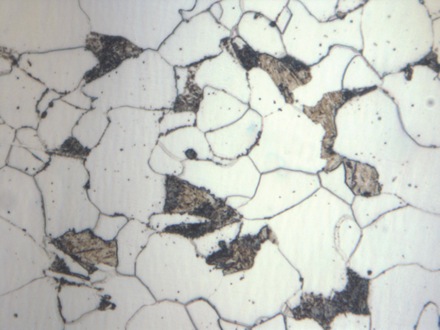

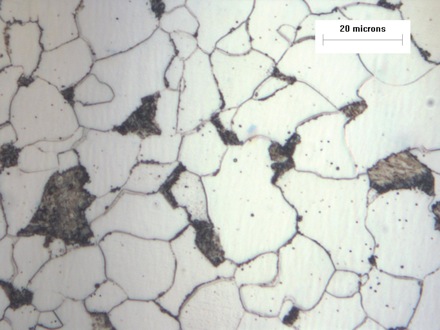

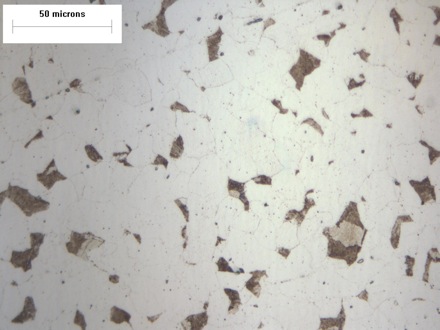

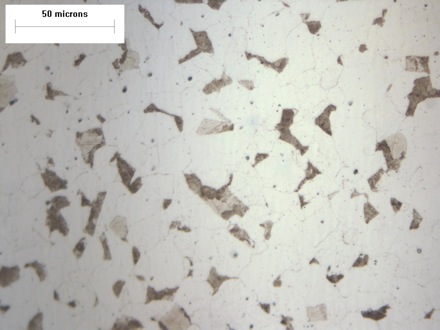

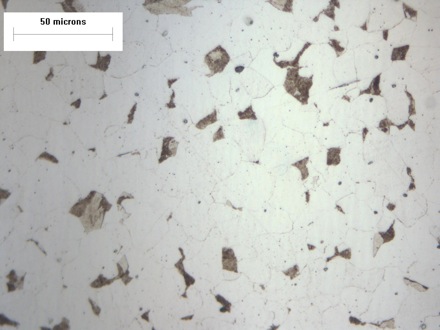

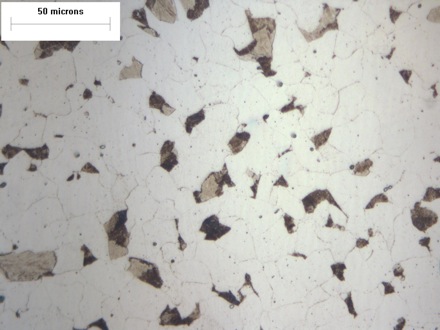

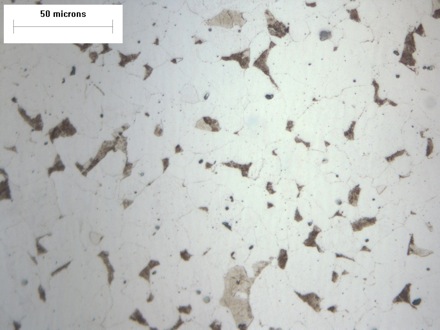

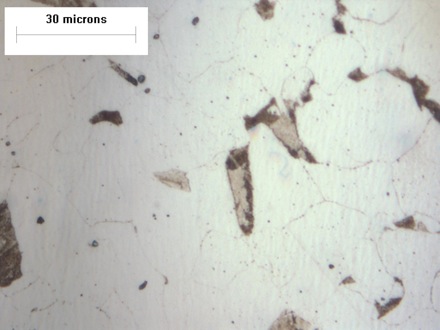

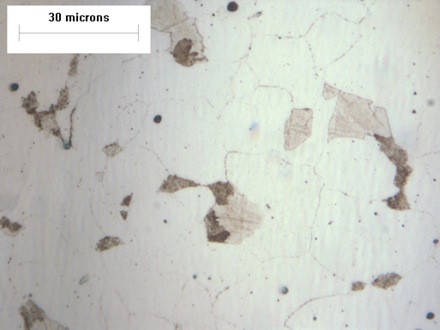

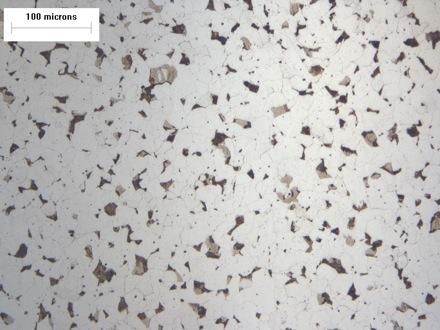

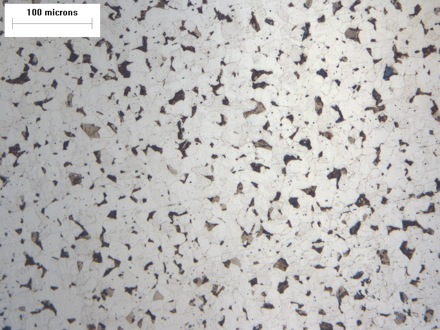

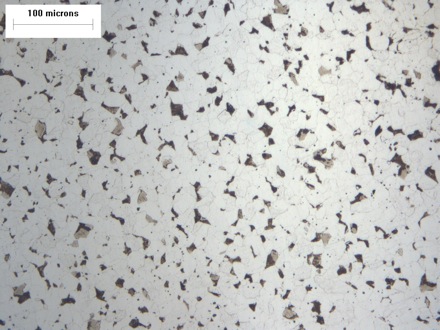

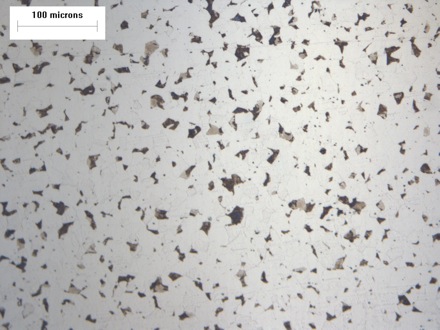

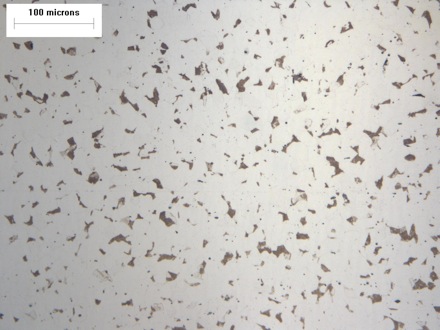

Much of the microstructure contsists of allotriomorphic ferrite. The remainder, darker etching, is more complex. |

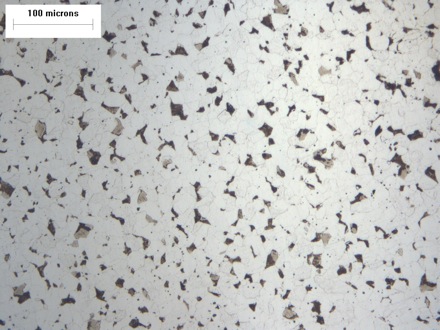

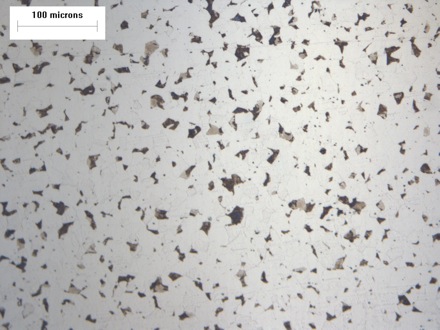

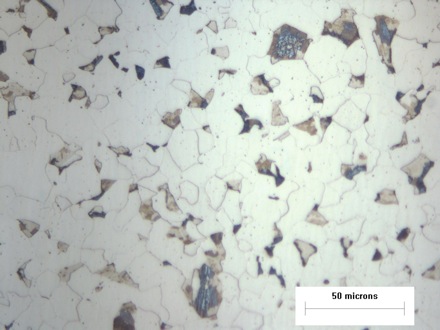

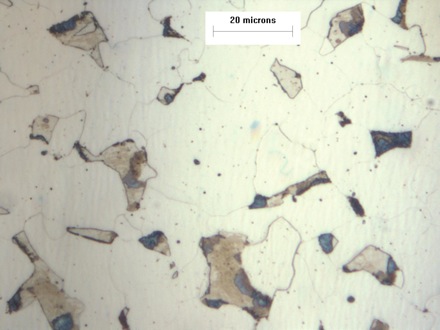

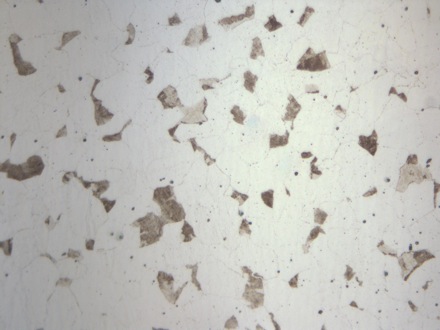

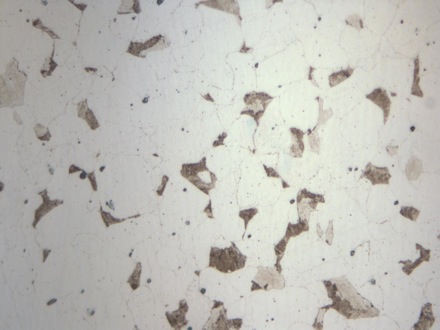

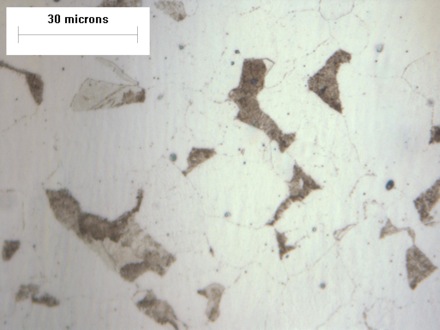

There are shades within the darker etching regions. |

|

|

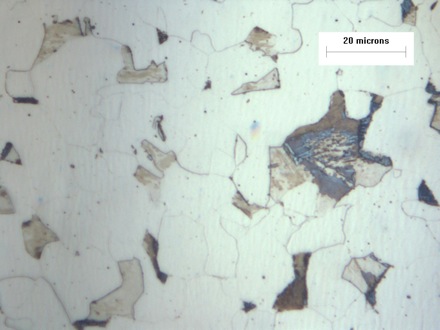

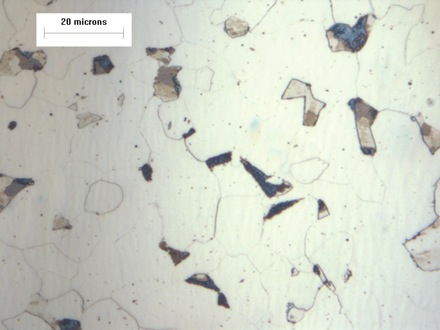

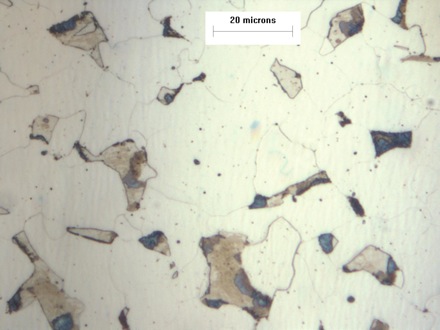

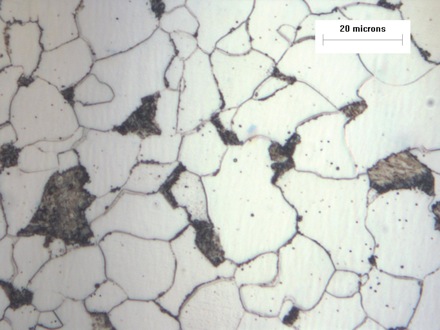

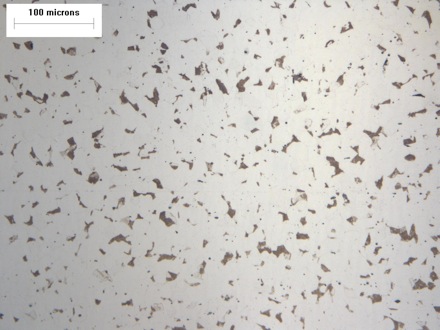

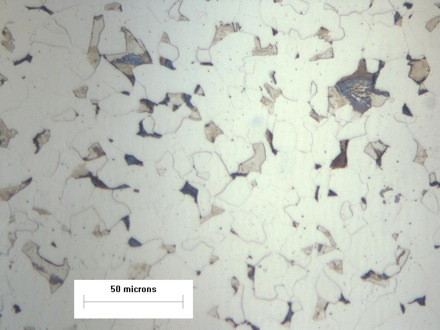

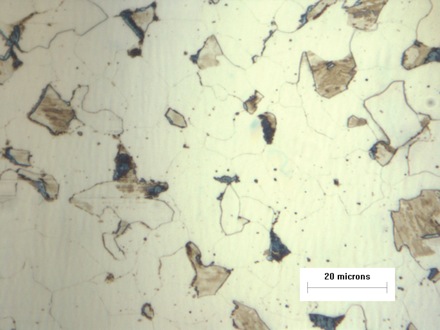

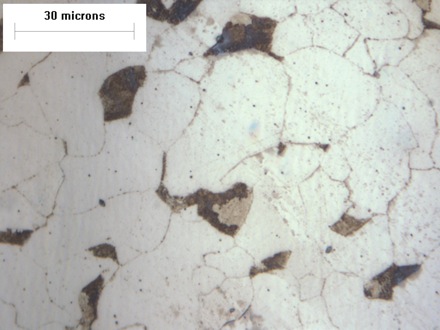

The darker regions were the last bits of austenite to transform. Withing these regions, the darkest contrast is from pearlite or bainite, and light-etching regions are untempered martensite. |

|

|

|

|

|

|

|

|

|

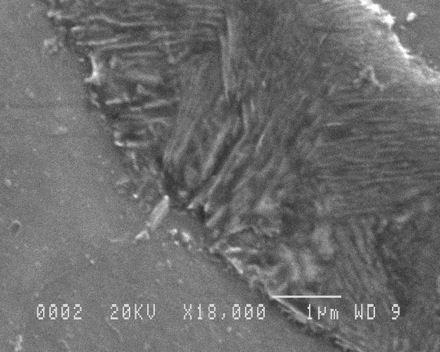

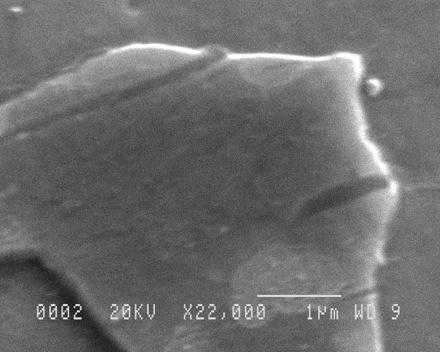

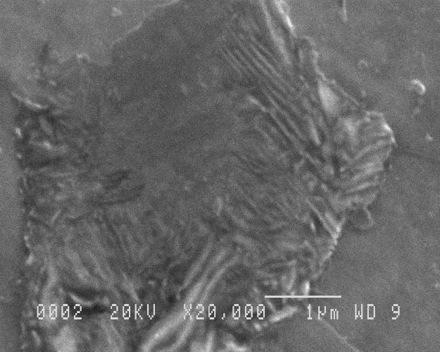

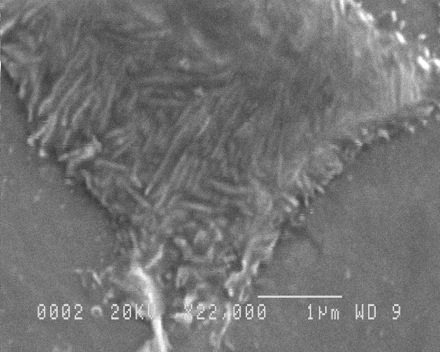

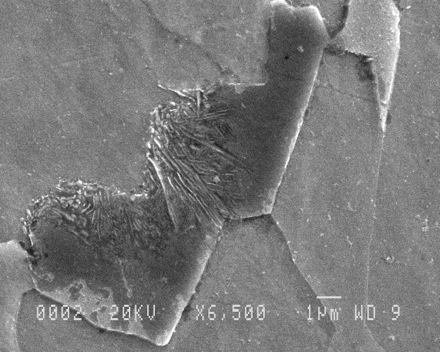

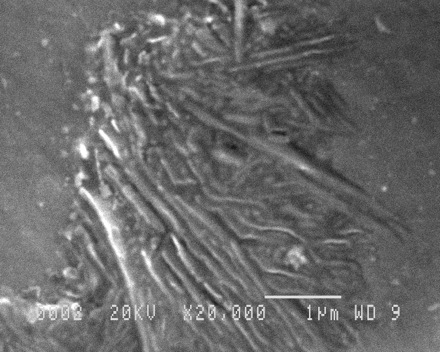

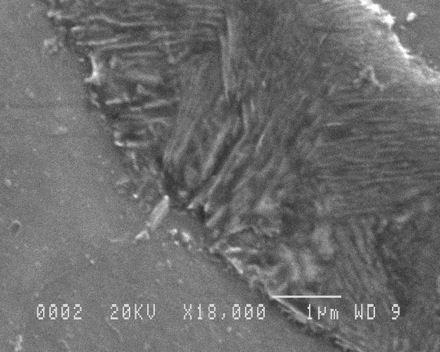

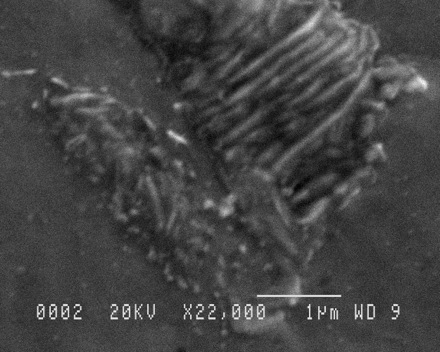

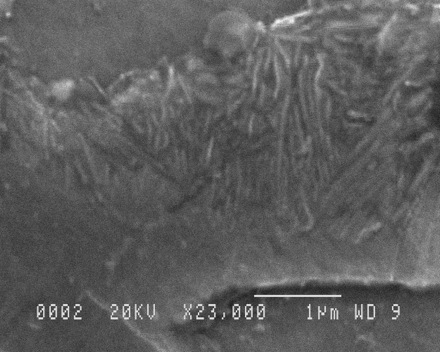

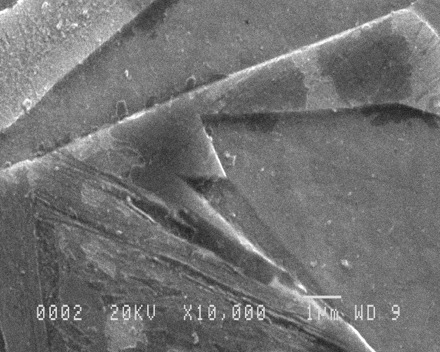

Scanning electron micrograph showing fine pearlite |

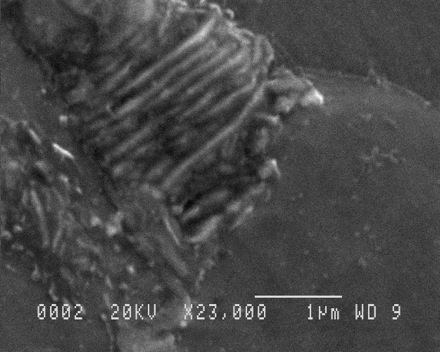

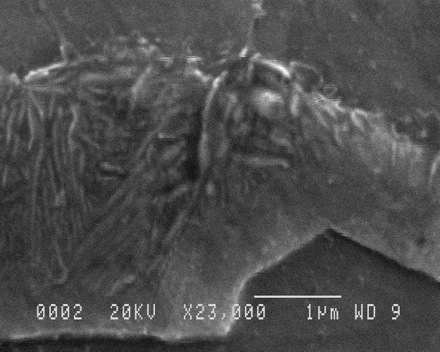

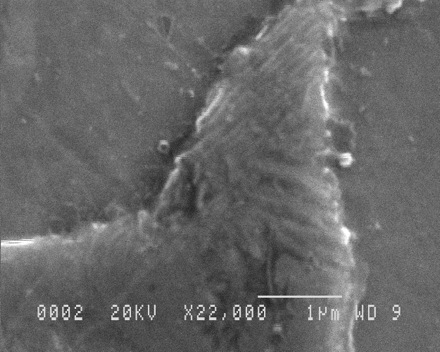

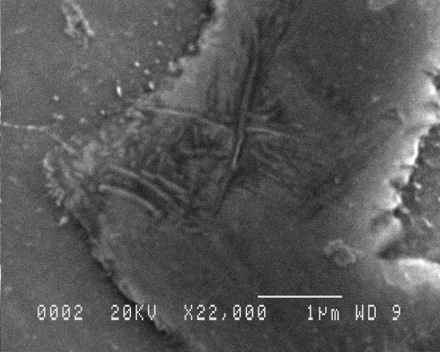

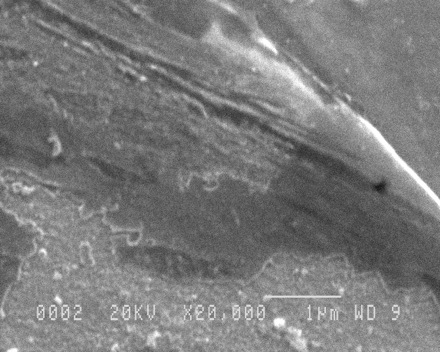

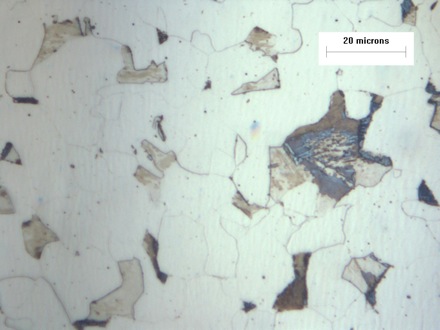

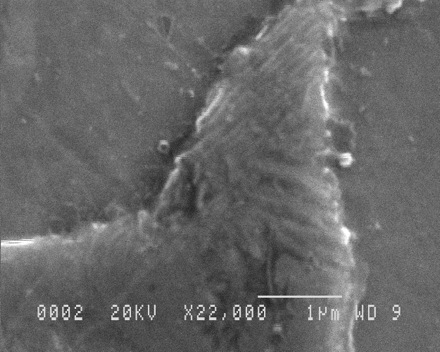

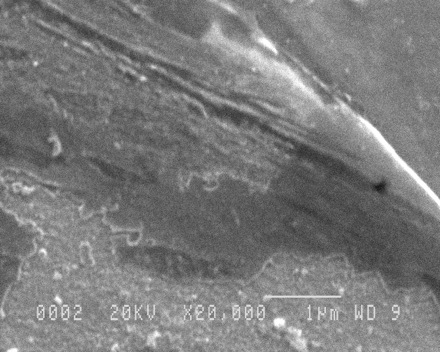

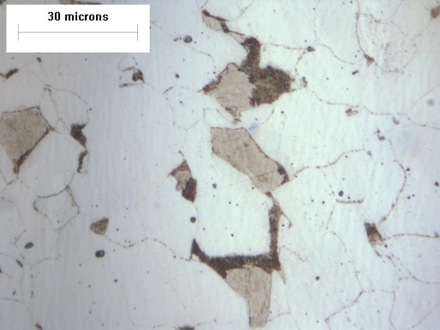

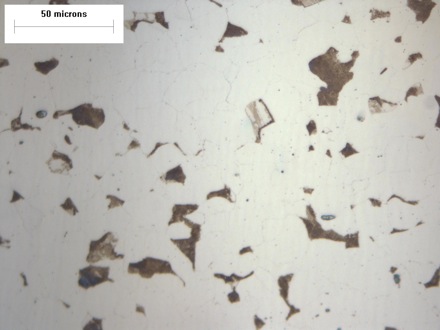

Here there are two plates of bainite within the dark-etching region |

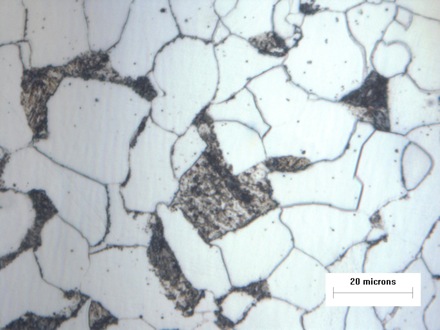

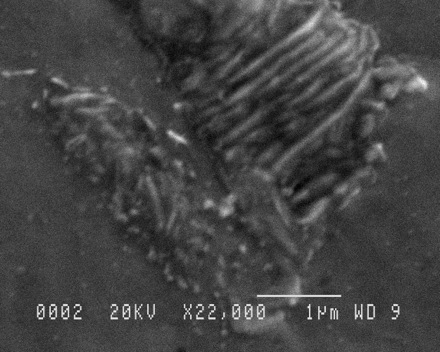

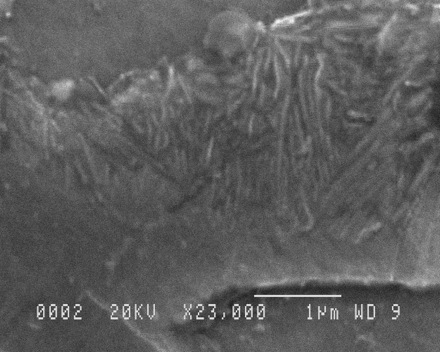

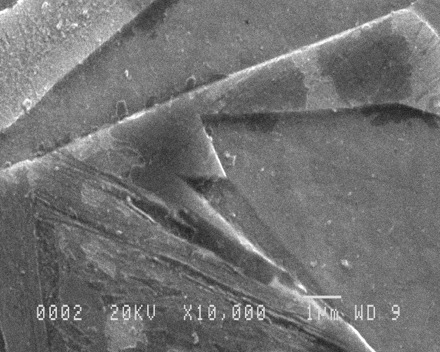

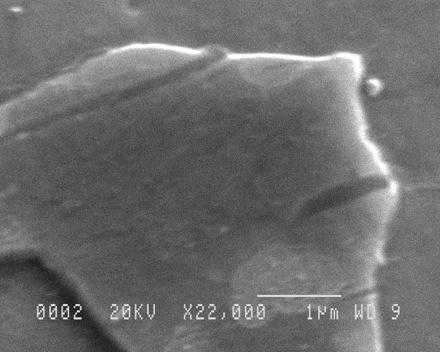

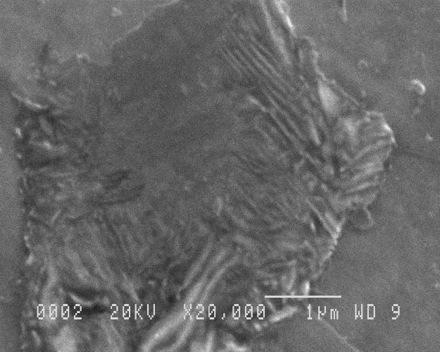

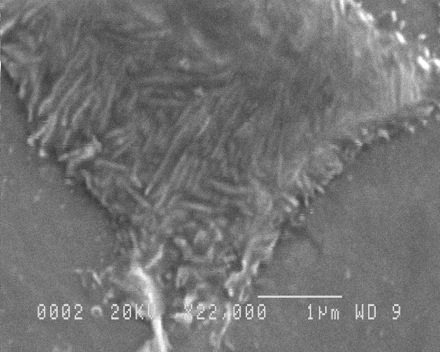

Partial transformation to pearlite |

|

|

|

|

|

|

|

|

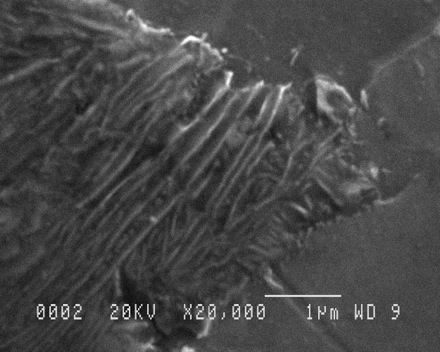

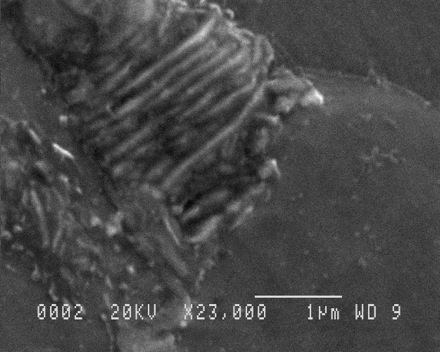

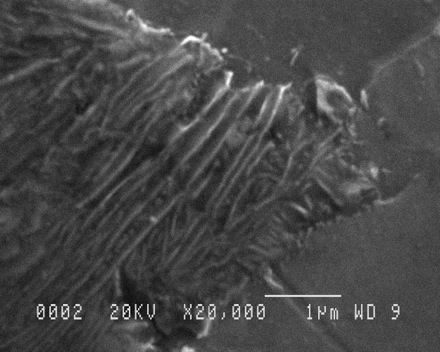

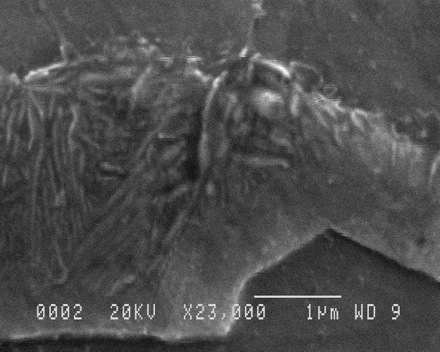

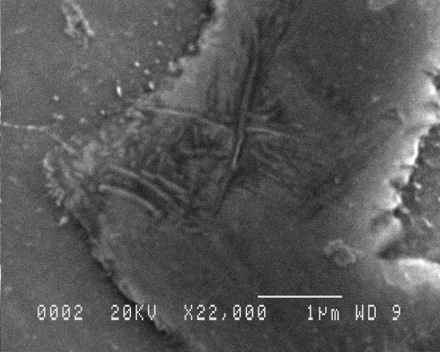

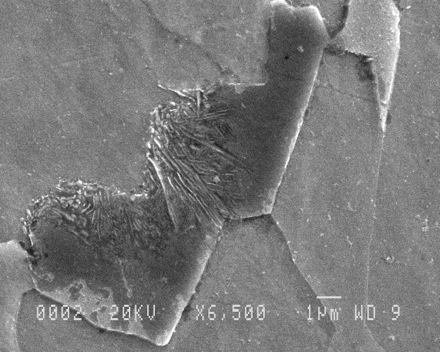

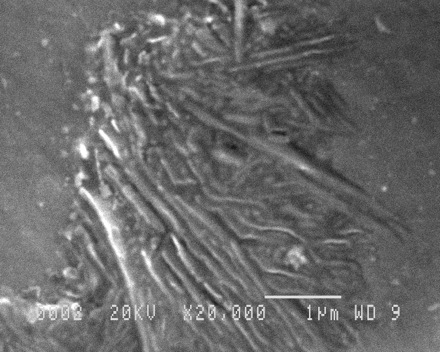

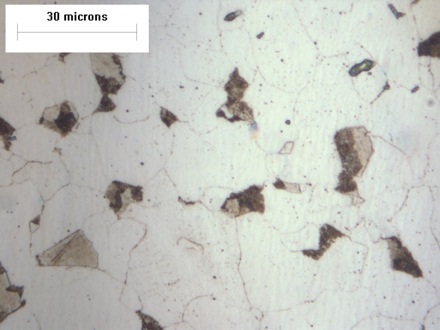

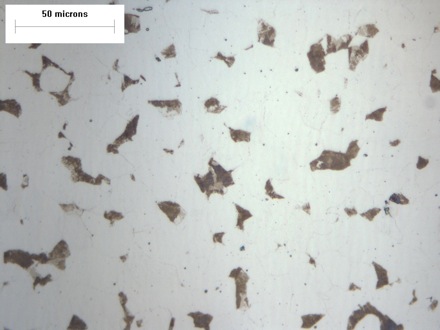

Bainite |

bainite plates |

Partial transformation to pearlite |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![[Queen Mary University of London]](https://www.phase-trans.msm.cam.ac.uk/QMUL.png)