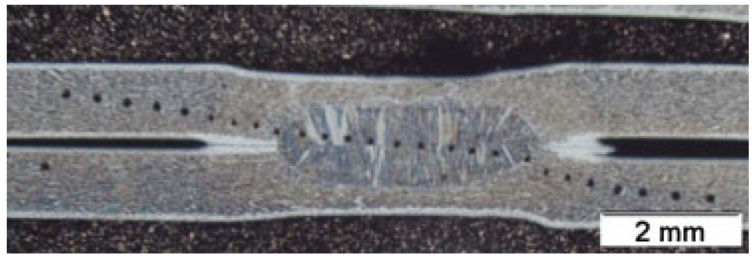

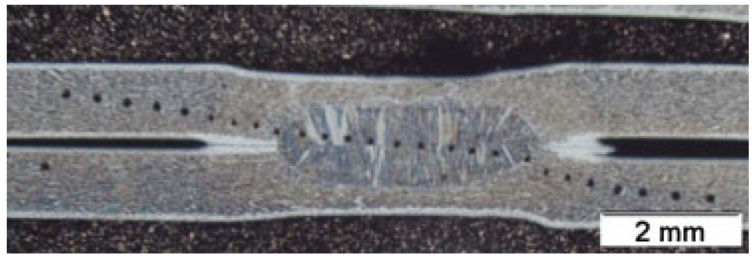

We examine here the spot welding characteristics of TRIP-assisted steels which contain δ-ferrite as a consequence of their aluminium concentrations of 3.5 or 5.6 wt%, and which also have high carbon contents of 0.3 or 0.4 wt% when compared with conventional automotive steels. The resistance spot welds are tested both in shear and cross tensile tests in order to determine the so-called ductility ratio which is a parameter associated with the fitness of such welds for automotive applications. With an increase of the δ-ferrite fraction from 0.19 to 0.5, the hardness variation across the weld and heat-affected zone is decreased approximately from 400 to 150 HV. It seems that the presence of stable δ-ferrite is helpful in reducing hardness variations, and in achieving a significant ductility ratio of 0.39.

Science and Technology of Welding and Joining, 17 (2012) 92-98.

| Envelope | Coefficients | Filling welds | Hot | Delta |

| Satoh | Fields | Piping | European welds | Poles |

| Mixed | Creep | Extraordinary ductility | Problems | Mechanical stabilisation |

| CML Home | Materials Algorithms |