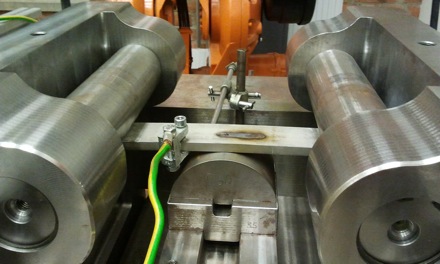

This is the largest Varestraint machine in the world, designed and built by Joel Andersson

Joel Andersson. The machine assesses the susceptibility of a weld to hot cracking.

The following movie and some of the photographs have kindly been provided by Dr Joel Andersson who built and installed the equipment at the University of the West in Sweden.

Metals often crack while cooling from the solidification temperature in circumstances where stresses develop as a result of constraint or heterogeneous cooling.

In the Varestraint test, a selected strain is applied to the sample during the course of welding. In this case, the strain is applied by bending at the point that the welding torch passes the point of contact between the sample and the mandrel. Welding continues while the bending is implemented. Note that the strain is parallel to the welding direction. The extent of cracking observed is an indication of the sensitivity to hot-cracking.

This is the largest Varestraint machine in the world, designed and built by Joel Andersson |

Joel Andersson. The machine assesses the susceptibility of a weld to hot cracking. |

A tiny crack is visible in the sample whcih has been through the Varestraint machine |

|

|

|

| PT Group Home | Materials Algorithms |