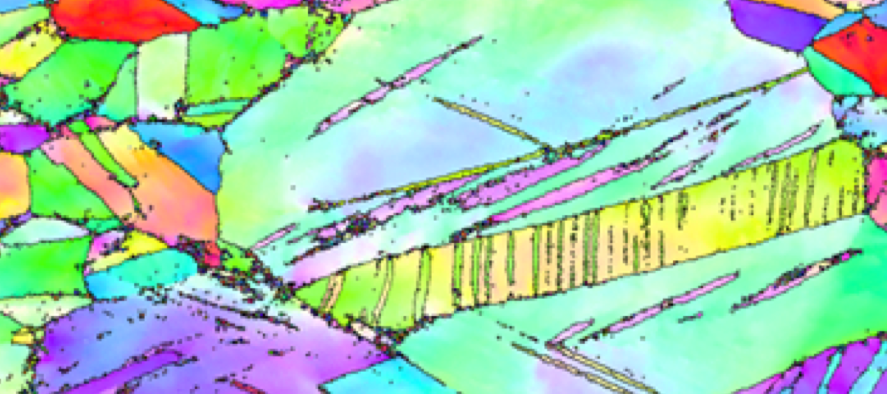

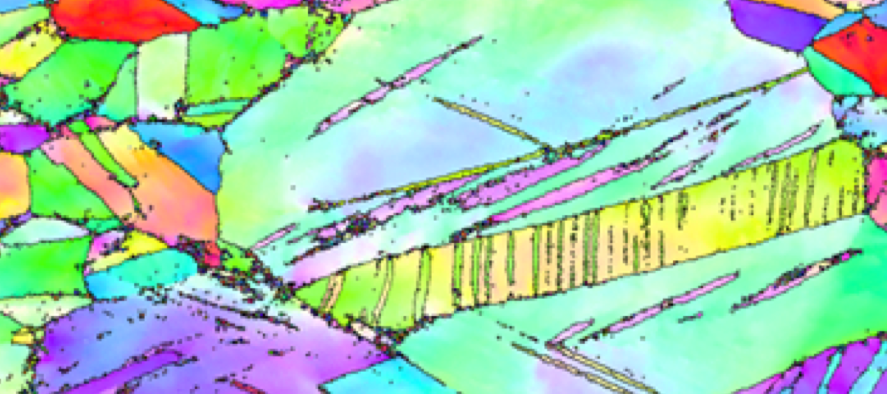

It is known empirically that the addition of aluminium as a solute in high-Mn austenitic steels dramatically improves their resistance to hydrogen-induced embrittlement. A variety of experimental techniques including the characterisation of trapping sites and high-resolution observation of fracture facets, have been used to reveal the mechanism by which aluminium induces this effect. It is found that transgranular fracture is promoted by the segregation of hydrogen to mechanical twin interfaces and to any ε-martensite that is induced during deformation. Since aluminium increases the stacking fault energy of austenite, the tendency for mechanical twinning is reduced, and the formation of deformation-induced martensite eliminated. These two effects contribute to the resistance of the aluminium-alloyed steel to hydrogen embrittlement.

Proceedings of the Royal Society A, 469 (2013), 20120458.

| Envelope | Coefficients | low density steel | Hot | Oxidation |

| Satoh | FSW maps | Powder metallurgy | Solidification | X80 pipes |

| Mixed | Mn-TRIP | Nuclear growth | Maraging | Tetragonal ferrite |

| PT Group Home | Materials Algorithms |