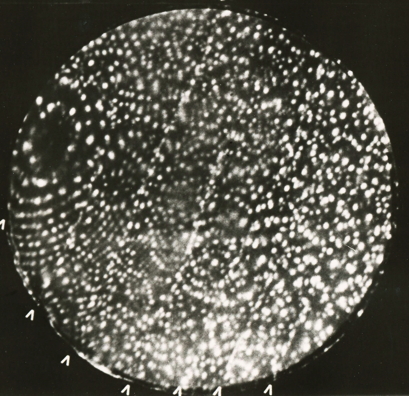

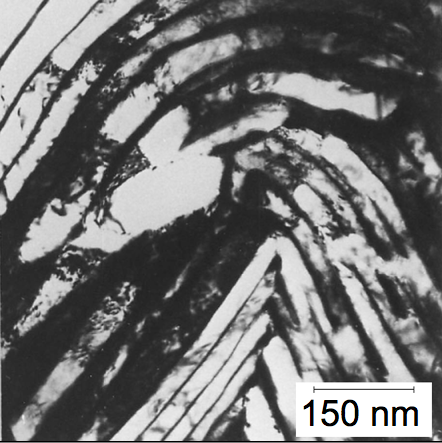

Transmission electron micrograph showing severely deformed structure.

See Paetke for more detail.

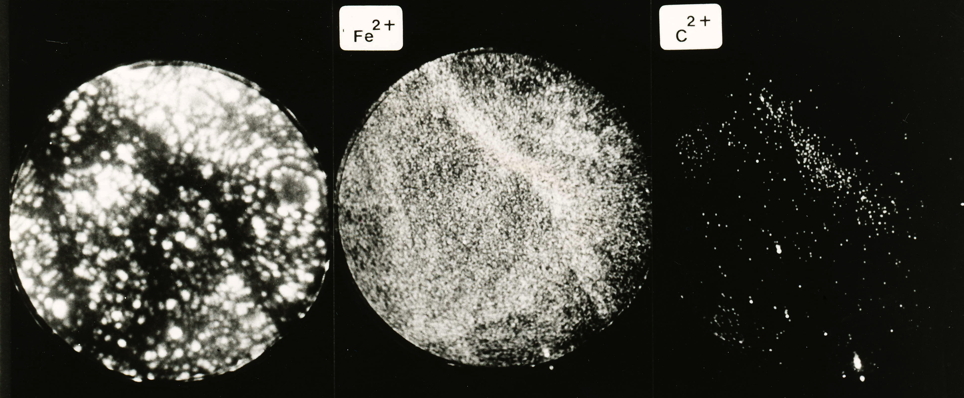

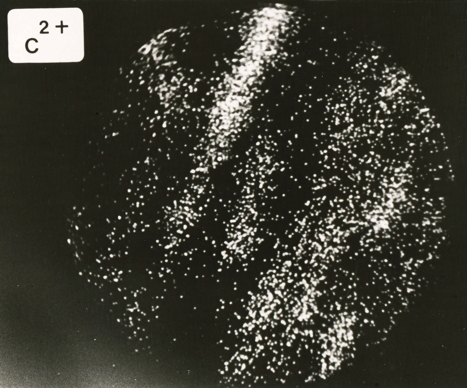

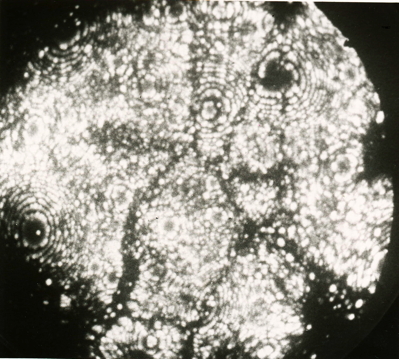

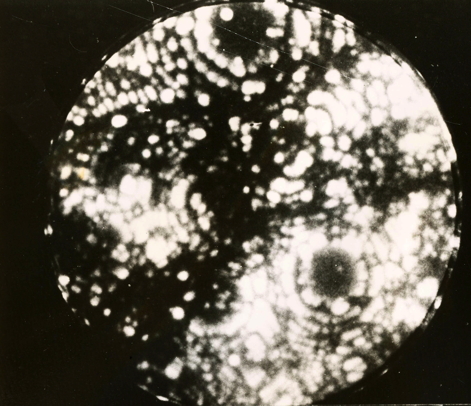

Field ion image of severely deformed structure.

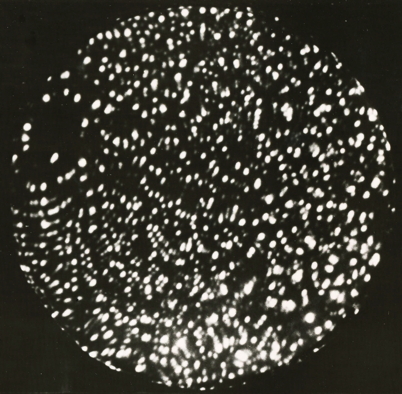

Field-ion image of the as-drawn wire.

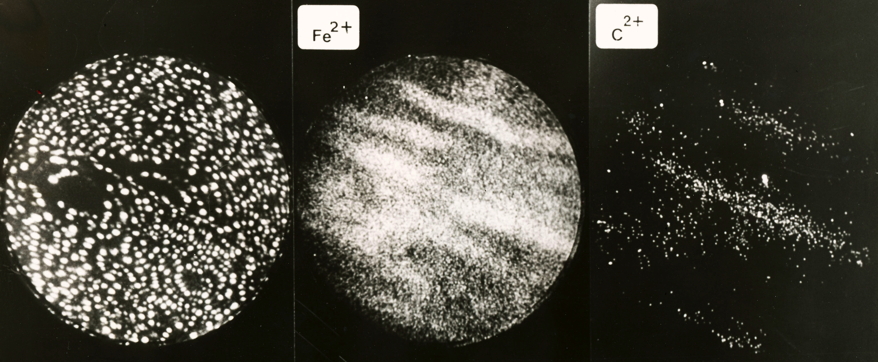

.

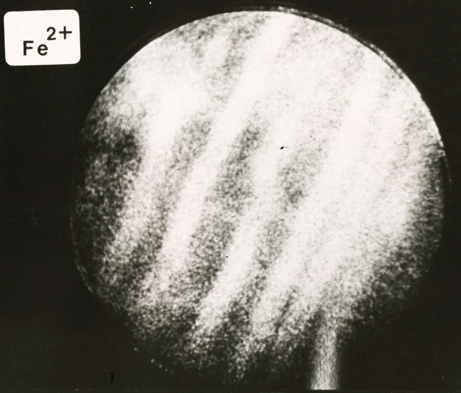

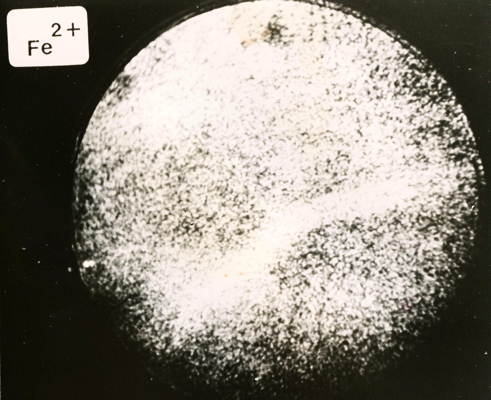

Corresponding Fe2+ image.

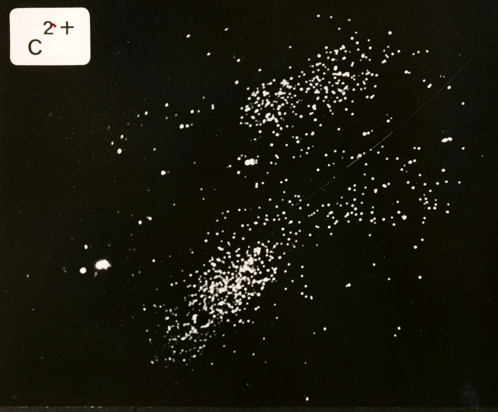

Corresponding C2+ image. The concentration of carbon is either close to

25 at.% (cementite) or 1-2 at.% in the ferrite.

The as-drawn wire has a 0.2% proof strength of about 1400 MPa. Plastic deformation of cementite can sometimes cause its dissolution, with carbon being introduced into the ferrite. This is because the carbon prefers to be at dislocations in ferrite than in the cementite lattice. Furthermore, if the cementite particle size is reduced to less than that of a critical nucleus, it will dissolve.