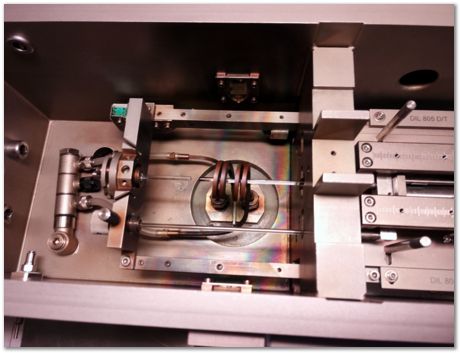

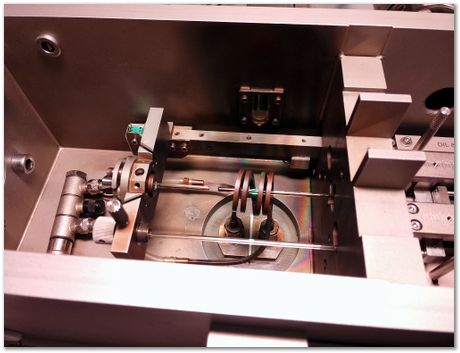

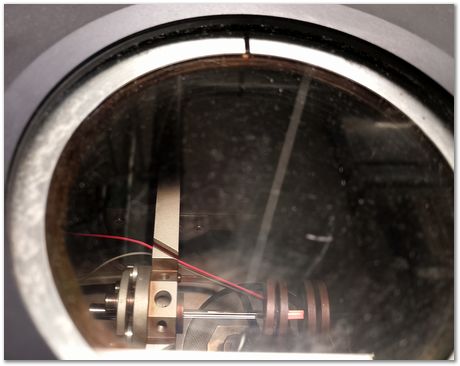

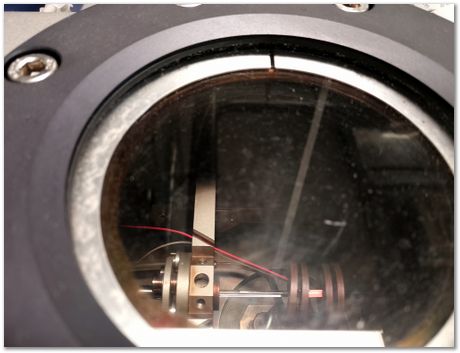

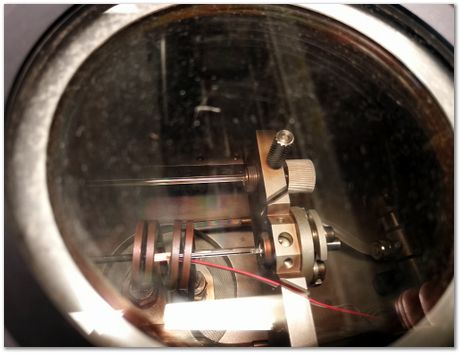

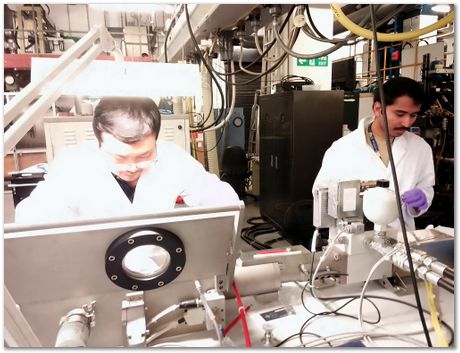

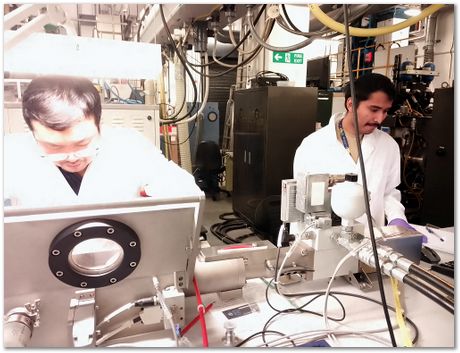

The chamber before loading the sample.

We were measuring length changes using a linear variable differential transformer, rather than a laser because the samples were only 3 mm in diameter.

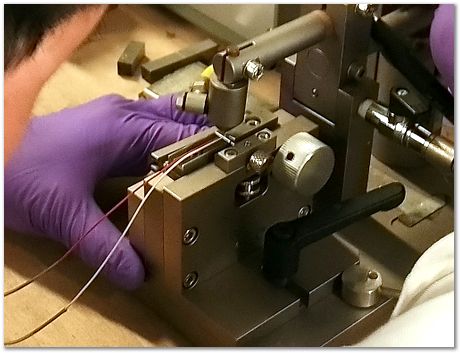

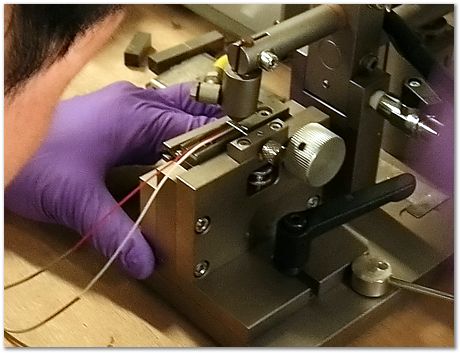

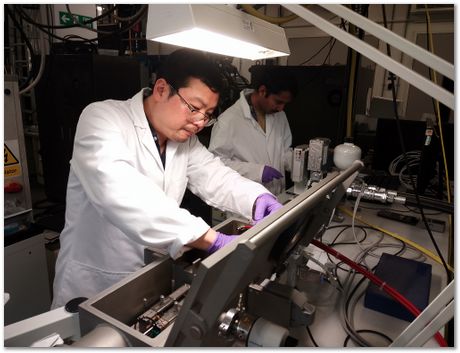

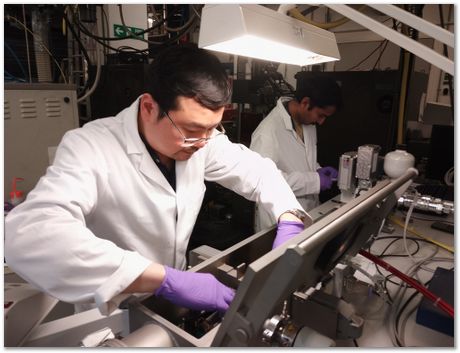

Equipment for the precise spot-welding of the thermocouple to the sample.

All the work was done by Steve.

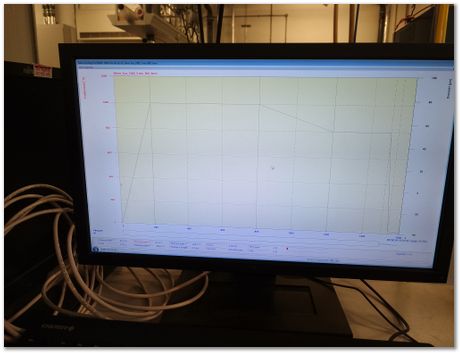

One of the programmed thermal cycles

Red-hot specimen inside the vacuum chamber.

Quenching was done using argon gas.

The samples have a high hardenability

Steve carefully placing the sample in position.

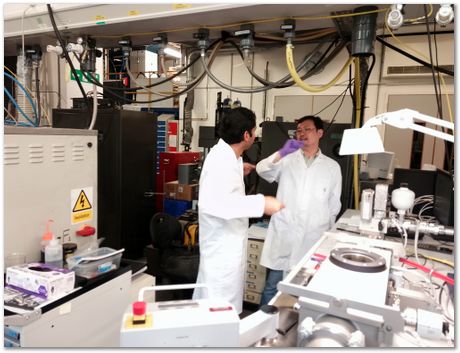

Rajdeep on the right.

Animated discussions.

III

III

III

![[Queen Mary University of London]](https://www.phase-trans.msm.cam.ac.uk/QMUL.png)