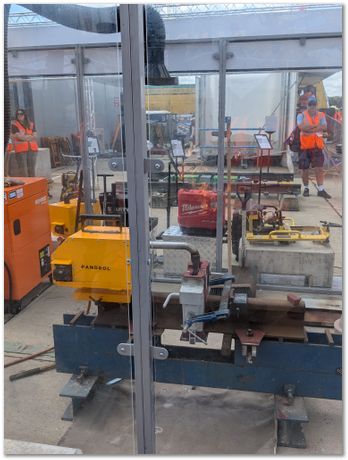

Setting up for the demonstration of aluminothermit welding of rails

The yellow "Pandrol" is a preheater powered by propane. This avoids the need for an oxygen cylinder as in oxy-acetylene burners.

When preheating is completed, the "Pandrol" is withdrawn.

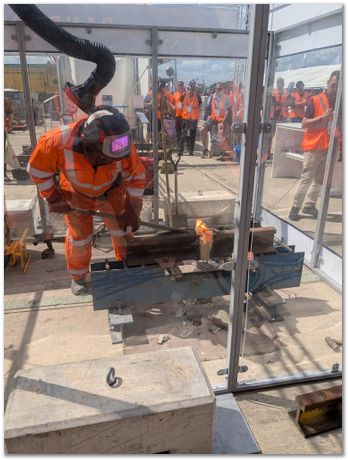

Here the object on top represents where the burning of aluminium produces molten iron which would then fill the gap between the rails.

After ignition

The brick-like objects enclose the molten metal around the original rail junction.

III

III

The completed joint which would then need to be ground down to the shape of the rail.

III

III

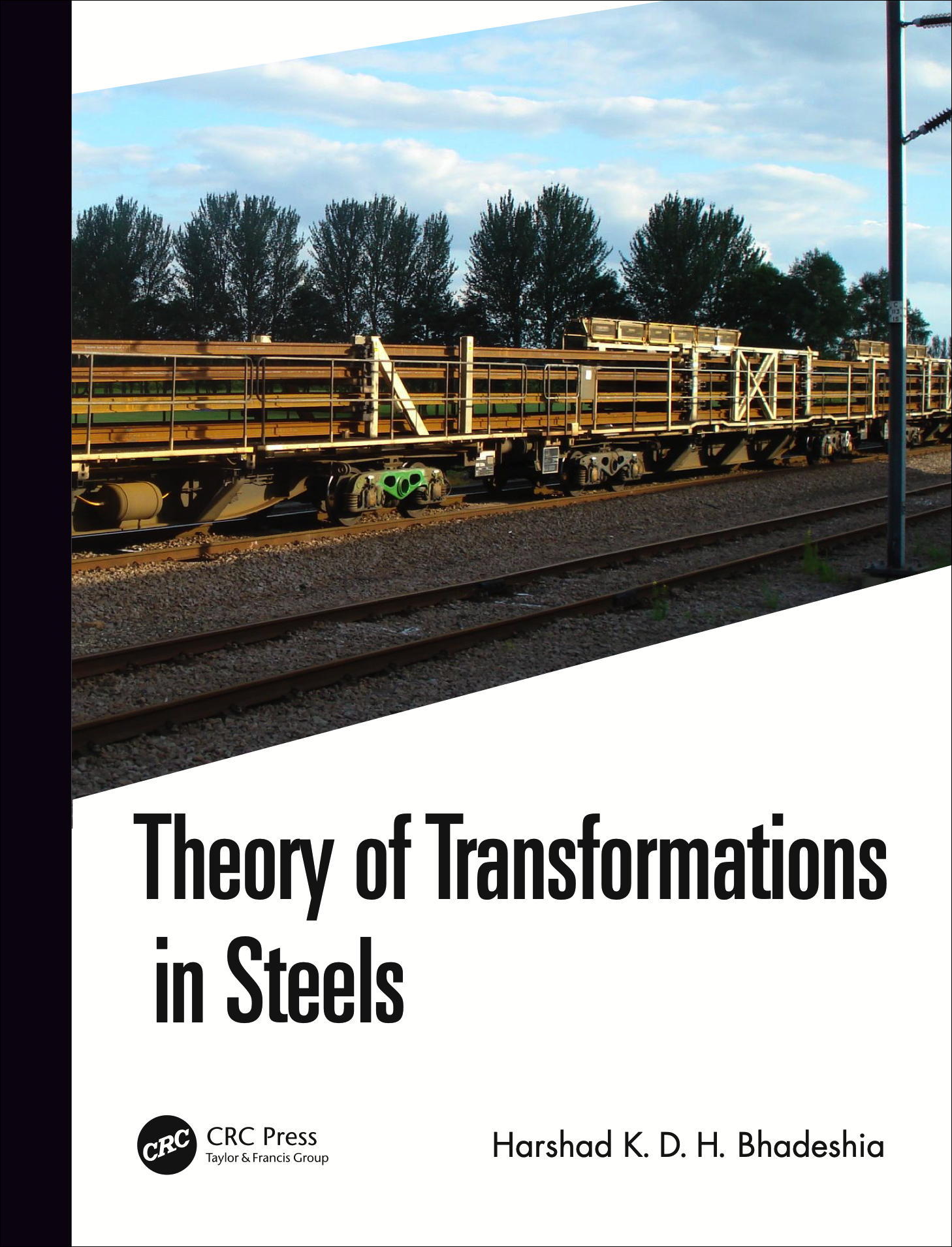

Rails are periodically ground on the surface to remove any fatigue cracks before they become an issue. However, this image illustrates a new procedure, "rail milling" which also removes fatigue cracks but is able to preserve the original geometry of the rail head.

III

The milling operation is conducted by a train that travels over the rails.

A typical rail crossing where a train can switch tracks.