![[MAP Logo]](https://www.phase-trans.msm.cam.ac.uk/map/maplogo1.gif)

C. N. Hulme-Smith

Phase Transformations Group,

Department of Materials Science and Metallurgy,

University of Cambridge,

27 Charles Babbage Road,

Cambridge, CB3 0FS, U.K.

E-mail: C. N. Hulme-Smith

Added to MAP: July 2018.

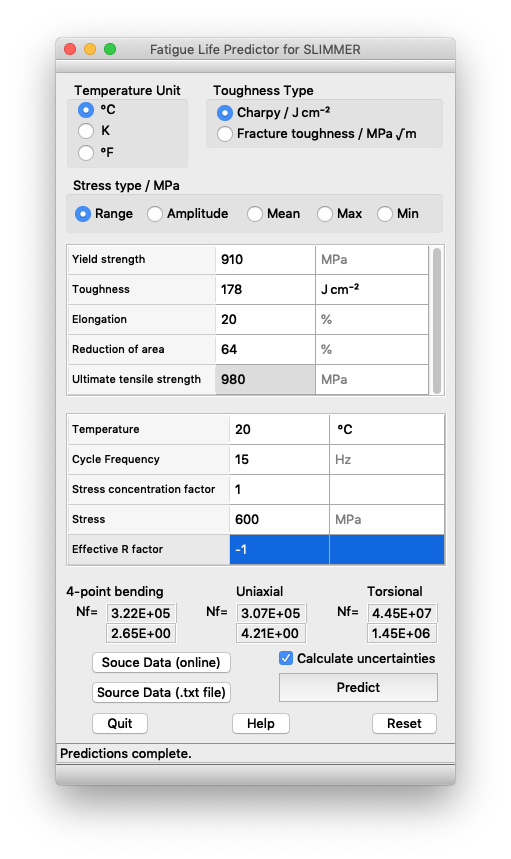

This program - the Fatigue Life Predictor for Steels (FLiPS) - uses an artificial neural network to predice the fatigue life for steels, based on their mechanical properties and test conditions. FLiPS uses a large database obtained from the Japanese National Research Institute for Metals (NRIM) fatigue data sheets, which are available fre-of-charge online. The data were used as an input to an artificial neural network, via Neuromat Model Manager software by Thomas Sourmail. The artificial neural network itself is built using the code Bigback5 by David MacKay.

FLiPS was originally written for the InnovateUK project Series production of Lightweight parts by Isostatic pressing of Metal powders to give Material and Energy Reduction (SLIMMER).

| Language: | Qt5 |

| Product form: | Graphical User Interface and QT project file |

| Platform: | Mac - tested on MacOS 10.13 (High Sierra) and MacOS 10.14 (Mojave); Windows - tested on Windows 10 only. The executables and accompanying files do not call external libraries and so they may well be compatible with earlier versions, but this has not been tested and is not guaranteed. |

Complete program.

FLiPS is a graphical interface for artificial neural networks that can simulate the fatigue life of steels in uniaxial, torsion or four-point bending loading. The input date were taken from fatigue data sheets published on the Japanese National Research Institute for Metals website. Neuromat Model Manager was used as a graphical interface to train the network, which was built using David MacKay's Bigback5 program.

The coefficients and matrices for the neural network were extracted after training and are hard-coded into FLiPS, which allows the user to calculate the expected fatigue life by simply entering simple mechanical properties and testing conditions into the graphical window. Uncertainties may also be calculated, if desired, which are calculated from coefficients that are derived using Bayesian statistics during the training of the model. These coefficients account for both uncertainty due to a lack of input data at the given value of each input parameter and the sensitivity of the network to variations about each specified input.

Dimitriu & Bhadeshia showed that fatigue crack growth rates can be predicted using an artificial neural network from mechanical properties and test conditions. FLiPS uses a similar approach to estimate fatigue life. Since artificial neural networksa are very flexible, they can capture complex physical relationships between input parameters and output, even if the analytical dependence is not known. In some cases, this leads to overfitting of data. However, Bigback5 penalises large dependencies, so they are only accepted if they lead to significant improvements in the predictions. A subset of the input data is also removed from the network training and is then used to test the fit. Both of these safeguard reduce the likelihood of overfitting the input data and lead to more robust neural networks. More information is provided in the documentation of Neuromat Model manager and in the technical note in reference 4.

For each of Mac and Windows, an executable is provided, along with supporting files. To run the model, simply double-click the executable, fill in the information required and press "Predict". These files must be kept in the same directory as the executable for the program to function correctly. A PDF user guide is also provided and may be copied to wherever the user wishes, but a copy must be kept in the same directory as the executable to ensure correct functionality of the "Help" button.

Files:

| FLiPS.exe (Windows), FLiPS.app (Mac) | Executable. |

| FLiPS_source_data.dat | Input data used to train the artificial neural network, in tab-delimited text format. |

| User manual | User manual for the graphical interface. |

| FLiPS.pro | Qt project file for FLiPS. This may be opened in Qt creator to develop the program. |

| FLiPS.pro.user | Ancillary Qt project file for FLiPS. This must be in the same directory as FLiPS.pro |

| main.cpp | C++ file that contains the instructions for calling the main program (mainwindow.cpp). |

| mainwindow.cpp | C++ file tcontianing all commands to perform calculations. The files …_lu_parameters.txt are hard-coded inside this file, which is why it is over 20 MB in size. |

| mainwindow.h | File containing commands to create all buttons in the graphical user interface. |

| mainwindow.ui | File containing the geometry and design of the window for the graphical user interface. |

| bending_lu_paramters.txt | Matrix of the lower-upper (LU) decomposition for the weights associated with the four-point bending fatigue neural network. |

| torsion_lu_paramters.txt | Matrix of the lower-upper (LU) decomposition for the weights associated with the torsional fatigue neural network. |

| uniaxial_lu_paramters.txt | Matrix of the lower-upper (LU) decomposition for the weights associated with the uniaxial fatigue neural network. |

| FLiPS_logo.icns | Icon file to give the graphical interface a dedicated icon in the Mac dock and the title bar of the graphical window. No icon files have been created for use in Windows. |

Follow the steps listed below to use the program:

Should a number result in a negative logarithm during the calculation, "NAN" will be displayed in the appropriate field after a prediction. Errors encountered by the user during the building of any future Qt project are specified in the Qt documentation.

An uncertainty estimation is provided, which is a factor by which the fatigue life may vary, within the confidence of the model, as explained in the Output section.

None.

None.

fatigue life, artificial neural network, Bayesian statistics, graphical user interface.

Windows executable and associated files.

Mac executable and associated files.

MAP originated from a joint project of the National Physical Laboratory and the University of Cambridge.