![[MAP Logo]](../../maplogo1.gif)

![[MAP Logo]](../../maplogo1.gif)

Mathew Peet

and

H.K.D.H. Bhadeshia,

Phase Transformations and Complex Properties Group,

Department of Materials Science and Metallurgy,

University of Cambridge,

Cambridge, U.K.

Based on mucg46, and mucg73.

A powerful suite of software for modelling of the thermodynamics and kinetics of solid-state transformations in steels. Calculates Widmanstatten, Bainite and Martensite start temperatures. This program corrects an inconsistency in MUCG73, where a modified free energy function for pure iron was substituted into MUCG46, without making adjustments to other algorithms. Here the program reverts to the free energy function of MUCG46 to restore consistency.

| Language: | FORTRAN 77 |

| Product form: | Source code and documentation in zipped tape archive file (.tar.gz). or zip file (.zip). |

See mucg83.f and included documentation files inside the file mucg83.tar.gz or .zip.

MAP_STEEL_MUCG83 is a modified version of MUCG73 and MUCG46.

The program asks for compositions (in wt.%) of eleven constituents to be supplied. There are maximum and minimum limits imposed on each constituent as shown :-

| Input Order |

Element | Max. (wt.%) | Min. (wt.%) |

|---|---|---|---|

| 1 | Carbon | 2.0 | 0.001 |

| 2 | Silicon | 2.5 | 0.0 |

| 3 | Manganese | 3.5 | 0.0 |

| 4 | Nickel | 3.5 | 0.0 |

| 5 | Molybdenum | 1.5 | 0.0 |

| 6 | Chromium | 3.5 | 0.0 |

| 7 | Vanadium | 1.5 | 0.0 |

| 8 | Cobalt | 4.0 | 0.0 |

| 9 | Copper | 4.0 | 0.0 |

| 10 | Aluminium | 2.0 | 0.0 |

| 11 | Tungsten | 4.0 | 0.0 |

The program will return an error message if these limits are exceeded.

The maximum number of different alloys which can be analysed in a single run is set by the variable J1 (currently 20).

These instructions have been compiled by Dr Sangeeta Khare.

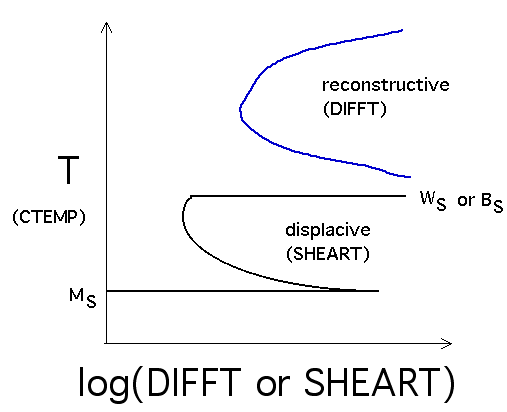

The data required to do this include the WS, BS, and MS temperatures, the temperature (CTEMP), the time required to initiate reconstructive transformations (DIFFT) and the time required to initiate displacive transformations (SHEART).

Plotting CTEMP versus SHEART gives the lower C-curve which has an upper cut-off at WS or BS, whichever is greater. Its lower limit is defined by the MS temperature.

The upper C-curve is obtained by plotting CTEMP versus DIFFT

The time axis is usually plotted on a logarithmic scale.

Allowable composition ranges limited - see Description.

No information supplied.

None.

N/A - complete program

1 1.0 0 0 0 0 0 0 0 0 0 0

******* NUMBER 1 *********

C= 1.0000 Si= 0.0000 Mn= 0.0000 Ni= 0.0000 Mo= 0.0000 Cr= 0.0000

V= 0.0000 Co= 0.0000 Cu= 0.0000 Al= 0.0000 W= 0.0000

C= 0.0449 Si= 0.0000 Mn= 0.0000 Ni= 0.0000 Mo= 0.0000 Cr= 0.0000

V= 0.0000 Co= 0.0000 Cu= 0.0000 Al= 0.0000 W= 0.0000

CARBON CONTENT= 0.04485 T10= 0.000000 T20= 0.000000 WGAMMA= 8054.

-------------------------------------------------------------------------------------------------------------------------------

FPRO FPROA GMAX CTEMP X NUCLEUS FSON XEQ XEQ50 FTO XTO VOLF X44 XTO400 SHEART DIFFT

-2021. -2586. -3105. 200. 0.87E-07 -3073. 0.2018 0.1920 -1171. 0.0903 0.7800 0.603E-01 0.0697 8 0.18E+05 0.25E+24

-1991. -2552. -3065. 205. 0.11E-06 -3038. 0.2005 0.1906 -1146. 0.0914 0.7786 0.605E-01 0.0696 2 0.13E+05 0.65E+23

-1959. -2516. -3025. 210. 0.13E-06 -3001. 0.1991 0.1891 -1121. 0.0915 0.7771 0.601E-01 0.0687 4 0.88E+04 0.18E+23

-1928. -2480. -2987. 215. 0.16E-06 -2964. 0.1978 0.1877 -1096. 0.0906 0.7755 0.596E-01 0.0679 4 0.62E+04 0.49E+22

-1896. -2445. -2959. 220. 0.20E-06 -2927. 0.1965 0.1862 -1071. 0.0893 0.7740 0.590E-01 0.0671 4 0.44E+04 0.14E+22

-1865. -2409. -2913. 225. 0.24E-06 -2890. 0.1951 0.1848 -1046. 0.0880 0.7724 0.585E-01 0.0663 4 0.32E+04 0.41E+21

.

.

.

-14. -73. -146. 645. 0.14E-02 -134. 0.0555 0.0204 0. 0.0189 0.1955 0.000E+00 0.0060 3 0.44E+04 0.15E+03

-9. -56. -118. 650. 0.14E-02 -105. 0.0533 0.0174 0. 0.0183 0.1612 0.000E+00 0.0050 4 0.12E+05 0.26E+03

-5. -40. -89. 655. 0.15E-02 -76. 0.0510 0.0143 0. 0.0175 0.1234 0.000E+00 0.0041 4 0.46E+05 0.58E+03

***** FTO VERSUS TEMPERATURE ****

WIDMANSTATTEN FERRITE START TEMPERATURE = 345. C

GROWTH LIMITED BAINITE START TEMPERATURE = 356. C

NUCLEATION LIMITED BAINITE START TEMP = 345. C

MARTENSITE START TEMPERATURE = 129. C

-------------------------------------------------------------------------------------------------------------------------------

MAP_STEEL_GMAAX

MAP_STEEL_HETRO

MAP_STEEL_OMEGA2

MAP_STEEL_AFEG

MAP_STEEL_CG

MAP_STEEL_DAFEG

MAP_STEEL_DCG

MAP_STEEL_ENERGY

MAP_STEEL_FTO1

MAP_STEEL_G91

MAP_STEEL_XALPH

Widmanstatten, bainite, martensite, start temperature

Download tar arhive containing source code.

Download zip file containing source code.

Download compiled executable for Windows

MAP originated from a joint project of the National Physical Laboratory and the University of Cambridge.