Typical coatings for high-temperature applications involve an oxidation

resistant coating and a thermal barrier coating (TBC). The oxidation resistant

coating is also called bond coat because it provides a layer on which the

ceramic TBC can adhere.

In many papers, TBC is used to refer to the ensemble bond-coat+TBC, in the

following, I will use TBC only to refer to the ceramic thermal barrier.

|

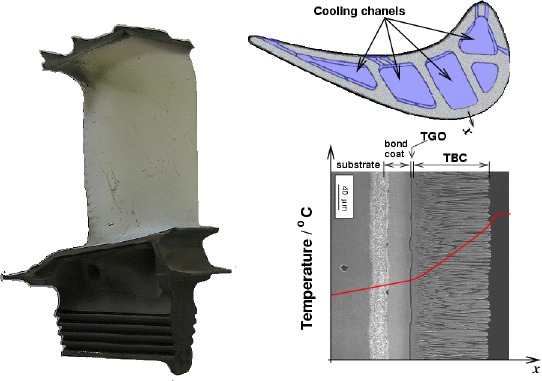

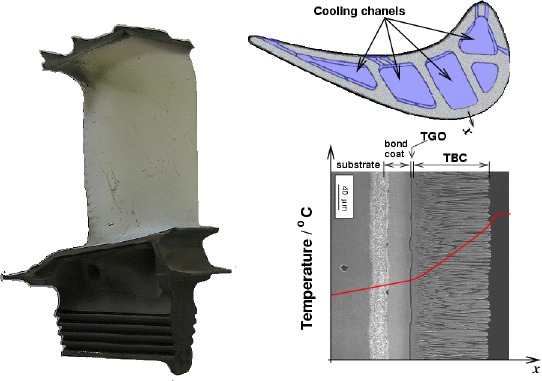

Illustration of a typical coating system in a high-pressure

turbine blade. Clockwise, a TBC coated high-pressure turbine blade, view

from top showing the cooling systems (image courtesy Michael Cervenka,

Rolls-Royce Plc), schematic profile temperature, note the drop of temperature

close to the blade surface due to the presence of a thin cooling air

film. |

As noted in the introduction, the TBC is oxygen transparent and therefore

does not provide any oxydation resistance.

Note: the following will make extensive use of these abbreviations:

- TGO:thermally grown oxide

- TBC:thermal barrier coating

- APS:air plasma spray

- LPPS:low pressure plasma spray

- EBPVD:electron beam physical vapour deposition

Bibliography

- Padture et al., Science, 296:2002, 280-284, 'Themal barrier coatings

for gas-turbine engine applications'.