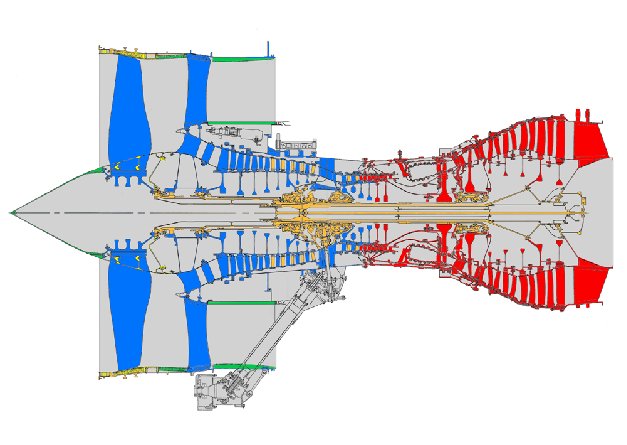

The different materials used in a Rolls-Royce jet engine. In

blue, titanium is ideal for its strength and density, but not at high

temperatures, where it is replaced by nickel-based superalloys (red). In orange:

steel used for the static parts of the compressor.

Image courtesy Michael Cervenka, Rolls-Royce