Worked Examples 1-4

Worked Examples 5-13

Worked Examples 14-20

Worked Examples 30-33

Explain separately the meanings of the left and right hand sides of this equation, and hence the origin of the equation.

How would similar conditions be derived for a ternary Fe-Mn-C alloy?

Hence describe two ways in which ferrite can grow in a ternary Fe-Mn-C alloy whilst maintaining local equilibrium at the interface, even though the diffusivities of Mn and C are different by many orders of magnitude.

Explain what is meant by the term paraequilibrium. Illustrate schematically an isothermal section of the paraequilibrium phase diagram for an Fe-Mn-C alloy where austenite and ferrite can coexist. The sketch should include a few tie-lines.

The boundary condition defined by the equation relates the interface velocity to the concentration gradient at the interface. The rate at which solute is partitioned as the interface moves ( i.e. left hand side) must equal that at which it is carried away by diffusion ( i.e. right hand side) if the compositions at the moving interface are to remain constant.

For a ternary alloy it would be necessary to satisfy two such equations

simultaneously, for each of the solutes:

Because

![]() these equations cannot in

general be simultaneously satisfied for the tie-line passing

through the alloy composition

these equations cannot in

general be simultaneously satisfied for the tie-line passing

through the alloy composition

![]() It is, however, possible to

choose other tie-lines which satisfy equation . If the tie-line

is such that

It is, however, possible to

choose other tie-lines which satisfy equation . If the tie-line

is such that

![]() (line

cd for alloy A of Figure 1a), then

(line

cd for alloy A of Figure 1a), then ![]() will become

very small, the driving force for carbon diffusion in effect

being reduced, so that the flux of carbon atoms is forced to

slow down to a rate consistent with the diffusion of manganese.

Ferrite forming by this mechanism is said to grow by a `

Partitioning, Local Equilibrium' (or PLE) mechanism, in

recognition of the fact that

will become

very small, the driving force for carbon diffusion in effect

being reduced, so that the flux of carbon atoms is forced to

slow down to a rate consistent with the diffusion of manganese.

Ferrite forming by this mechanism is said to grow by a `

Partitioning, Local Equilibrium' (or PLE) mechanism, in

recognition of the fact that

![]() can

differ significantly from

can

differ significantly from

![]() , giving

considerable partitioning and long-range diffusion of manganese into the

austenite (Coates, 1973c).

, giving

considerable partitioning and long-range diffusion of manganese into the

austenite (Coates, 1973c).

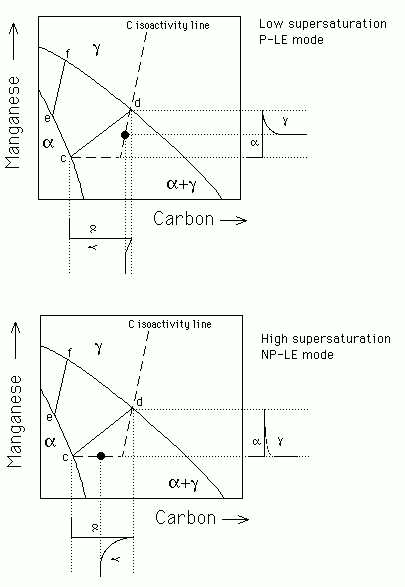

Figure 1: Schematic

isothermal sections of the Fe-Mn-C system, illustrating ferrite growth

occurring with local equilibrium at the

![]() interface.

(a) Growth at low supersaturations (P-LE) with bulk redistribution of

manganese, (b) growth at high supersaturations (NP-LE) with negligible

partitioning of manganese during transformation. The bulk alloy

compositions are designated by the symbol

interface.

(a) Growth at low supersaturations (P-LE) with bulk redistribution of

manganese, (b) growth at high supersaturations (NP-LE) with negligible

partitioning of manganese during transformation. The bulk alloy

compositions are designated by the symbol ![]() in each case.

in each case.

An alternative choice of tie-line could allow

![]() (line cd for alloy B

of Figure 1b), so that

(line cd for alloy B

of Figure 1b), so that ![]() is drastically increased

since only very small amounts of Mn are partitioned into the

austenite. The flux of manganese atoms at the interface correspondingly

increases and manganese diffusion can then keep pace with that of

carbon, satisfying the mass conservation conditions of

equation . The growth of ferrite in this manner is said to occur

by a `Negligible Partitioning, Local Equilibrium' (or NPLE) mechanism,

in recognition of the fact that the manganese content of the ferrite

approximately equals

is drastically increased

since only very small amounts of Mn are partitioned into the

austenite. The flux of manganese atoms at the interface correspondingly

increases and manganese diffusion can then keep pace with that of

carbon, satisfying the mass conservation conditions of

equation . The growth of ferrite in this manner is said to occur

by a `Negligible Partitioning, Local Equilibrium' (or NPLE) mechanism,

in recognition of the fact that the manganese content of the ferrite

approximately equals

![]() , so that little if any

manganese partitions into austenite.

, so that little if any

manganese partitions into austenite.

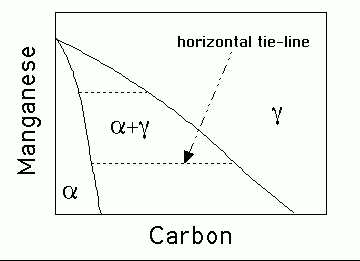

Paraequilbrium is a constrained equilibrium (Figure 2). It occurs at temperatures where the diffusion of substitutional solutes is not possible within the time scale of the experiment. Nevertheless, intersitials may remain highly mobile. Thus, in a steel, manganese does not partition between the ferrite and austenite, but subject to that constraint, the carbon redistributes until it has the same chemical potential in both phases.

Therefore, the tie-lines in the phase diagram are all virtually parallel to the carbon axis, since Mn does not partition between ferrite and austenite.

Figure 2: Paraequilibrium

phase diagram.

(ii) Sketch the three main kinds of phase diagrams found for

titanium alloys given that some solutes stabilise ![]() , some

stabilise

, some

stabilise ![]() and others are neutral. On the diagram for

and others are neutral. On the diagram for ![]() stabilising elements, construct and justify a curve defining the locus of

the martensite-start temperature as a function of the solute

concentration.

stabilising elements, construct and justify a curve defining the locus of

the martensite-start temperature as a function of the solute

concentration.

(iii) Why is the eutectoid reaction found in some titanium alloys so sluggish compared with the formation of pearlite in steels?

(iv) Giving reasons, state typical applications for Ti-Pd and Ti-V-Al alloys.

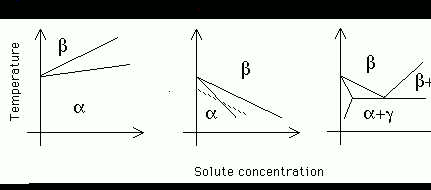

The three types of phase diagrams are illustrated below, for ![]() ,

,

![]() and neutral elements which lead to a eutectoid phase diagram.

The locus of

and neutral elements which lead to a eutectoid phase diagram.

The locus of ![]() temperatures is indicated as a dashed line, with

sufficient undercooling to account for strain energy and solute

supersaturation.

temperatures is indicated as a dashed line, with

sufficient undercooling to account for strain energy and solute

supersaturation.

Figure 3: Phase

diagrams for titanium.

The eutectoid reaction, for example in the Ti-Cu alloys, involves the solid-state diffusion of substitutional solutes which diffuse at a far smaller rate than intersitial carbon in iron. Consequently, it is frequently possible to avoid the eutectoid reaction by cooling rapidly.

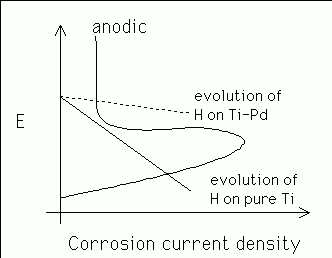

The addition of a small amount (![]() wt%) of paladium to titanium

makes it much more corrosion resistant in acid. This is because the

hydrogen evolution reaction is less polarised (hydrogen evolution is

easier), causing the cathodic reaction curve to intersect the cathodic

reaction curve in the passive region, leading to a smaller corrosion

current (Figure 3).

wt%) of paladium to titanium

makes it much more corrosion resistant in acid. This is because the

hydrogen evolution reaction is less polarised (hydrogen evolution is

easier), causing the cathodic reaction curve to intersect the cathodic

reaction curve in the passive region, leading to a smaller corrosion

current (Figure 3).

Ti-6Al-4V is a classic ![]() alloy with high strength

combined with a low density. The

alloy with high strength

combined with a low density. The ![]() phase is harder and enhances

the overall strength, the aluminium helping to stabilise

phase is harder and enhances

the overall strength, the aluminium helping to stabilise ![]() and

lower the density. However, 6Al needs to be balanced by the 4V which is

an

and

lower the density. However, 6Al needs to be balanced by the 4V which is

an ![]() stabiliser. The alloy is widely used in sheet and forgings

for the aerospace industries.

stabiliser. The alloy is widely used in sheet and forgings

for the aerospace industries.

(a) martensite, Widmanstätten ferrite and bainite all occur in the form of thin plates;

(b) Widmanstätten ferrite grows at a rate which is much smaller than the speed of sound in the metal;

(c) an Fe-30Ni wt% martensite is weak compared with martensite in Fe-0.2C wt% alloy;

(d) alloying elements have a much greater effect on the kinetics of a reconstructive transformation when compared with the corresponding effect on displacive transformations..

Widmanstätten ferrite occurs at temperatures where diffusionless transformation is thermodynamically impossible. Thus, although the change in crystal structure is accomplished by a deformation, the displacements occur at a rate controlled by the diffusion of carbon in the austenite ahead of the interface.

Carbon causes a much greater degree of hardening than any substitutional solute. This is because it leads to a tetragonal distortion of the b.c.c. structure; a tetragonal strain can interact with all components of the stress field of a dislocation. Substitutional solutes cause isotropic strains which can only interact with the small hydrostatic component of stress associated with edge dislocations.

The effect on displacive transformations is thermodynamic alone. On reconstructive transformations the solute may partition between the parent and product phases by a process involving diffusion. This will have a further kinetic effect on reconstructive transformations.

Given that the Bain strain, which changes the face-centered cubic austenite lattice into that of body-centered cubic martensite is an invariant-line strain, explain why the observed shape deformation accompanying martensitic transformation is an invariant-plane strain.

Why is the lattice-invariant deformation unnecessary when austenite transforms by a martensitic mechanism to a hexagonal close-packed lattice?

Why is martensite hard in steels but not so in iron or in non-ferrous metals and alloys?

Note that it is not correct to state that the transformation must occur at high speeds or at low temperatures, that it requires rapid quenching or that martensite is hard.

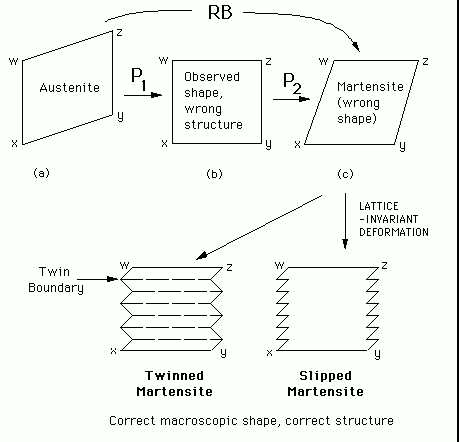

The phenomenological theory of

martensite crystallography solves this problem (Figure 4). The

Bain strain converts the structure of the parent phase into that of the

product phase. When combined with an appropriate rigid body rotation,

the net homogeneous lattice deformation ![]() is an

invariant-line strain (step

is an

invariant-line strain (step ![]() to

to ![]() in Figure 4). However, the

observed shape deformation is an invariant-plane strain

in Figure 4). However, the

observed shape deformation is an invariant-plane strain ![]() (step

(step ![]() to

to ![]() in Figure 4), but this gives the wrong crystal structure.

If a second homogeneous shear

in Figure 4), but this gives the wrong crystal structure.

If a second homogeneous shear ![]() is combined with

is combined with

![]() (step

(step ![]() to

to

![]() ), then the correct structure is obtained but the wrong shape since

), then the correct structure is obtained but the wrong shape since

The theory explains all the observed features of the martensite crystallography. The orientation relationship is predicted by deducing the rotation needed to change the Bain strain into an invariant-line strain. The habit plane does not have rational indices because the amount of lattice-invariant deformation needed to recover the correct the macroscopic shape is not usually rational. The theory predicts a substructure in plates of martensite (either twins or slip steps) as is observed experimentally. The transformation goes to all the trouble of ensuring that the shape deformation is macroscopically an invariant-plane strain because this reduces the strain energy when compared with the case where the shape deformation might be an invariant-line strain.

Figure 4: The

phenomenological theory of martensite crystallography.

Notice that in the case of the fcc-hcp transformation, the lattice

deformation (Bain Strain) itself is an invariant-palne strain, i.e. the

motion of Shockley partials on the alternate close-packed planes.

B![]() so a lattice invariant deformation is not needed. There

are no transformation twins or slip steps to be found.

so a lattice invariant deformation is not needed. There

are no transformation twins or slip steps to be found.

The carbon atom in a b.c.c. lattice causes a tetragonal strain because it resides in an irregular octahedral hole, whose axes are given by the cell edge and two orthogonal face diagonals. A tetragonal strain can interact with both shear and hydrostatic components of stress. Thus, there is a strong interaction with both screw and edge dislocations. By contrast, substitutional solutes (and carbon in austenite) only cause isotropic volume changes which can only interact with the hydrostatic component of stress from edge dislocations, i.e. a weak interaction.

(ii) Explain the cause of precipitate-free zones and how they might be avoided.

(iii) Why are aluminium-silicon alloys good as casting alloys? How might their microstructures be improved?

It is possible, at large driving forces, for precipitates to nucleate homogeneously. However, it is more common for nucleation to occur heterogeneously because there is a gain in energy as the defect on which the particle forms is partly or wholly eliminated.

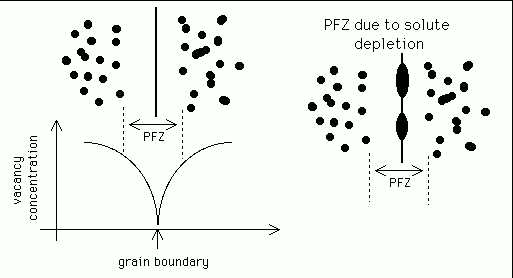

Vacancies are a prominent nucleation site for many precipitates, particularly in aluminium alloys where the concentration of vacancies tends to be high. However, there is a vacancy denuded zone next to a grain boundary (which is a sink for vacancies), Figure 5. There will, therefore, be a precipitate-free zone (PFZ) adjacent to a grain boundary.

Figure 5:

Precipitate-free zones.

An alternative reason for PFZ formation is that nucleation happens first on grain boundaries which are themselves potent nucleation sites. These precipitates drain the adjacent matrix from solute and hence a solute depleted PFZ arises, with coarse particles at the boundaries.

Precipitate-free zones can be eliminated by a two-stage heat treatment

where nucleation is induced homogeneously at a low temperature, and the

precipitates are then allowed to grow at a higher temperature (Figure 6).

Thus, for Al-6Zn-3Mg age-hardening alloy, GP zones are used as nuclei

for the ![]() (

(![]() phase.

phase.

twostage22294400Figure 6: Two-stage heat treatment

Aluminium casting alloys closely resemble cast irons.

Aluminium-12 wt% silicon eutectic compositions are frequently used

because this gives the minimum melting temperature. The silicon which

has a density of just 2.34

![]() , precipitates virtually as

pure silicon. The resulting expansion compensates for freezing

contractions to give castings with minimal porosity.

, precipitates virtually as

pure silicon. The resulting expansion compensates for freezing

contractions to give castings with minimal porosity.

The silicon is coarse and brittle. The addition of a minute quantity of sodium (0.02 wt%) greatly refines the Si particles giving a higher toughness. It does so by removing P; AlP is a good nucleant for Si so its removal allows solidification to occur at a higher undercooling, where the nucleation rate can be larger.

(b) Explain why the most popular titanium alloy contains both aluminium and vanadium as alloying additions.

(c) Giving one example, explain what is meant by solute trapping.

(d) Distinguish between martensite, lower bainite, upper bainite and Widmanstätten ferrite.

Figure 6: Corrosion of

Ti and Ti-Pd.

Aluminium reduces the density of Ti and stabilizes and strengthens the

![]() phase while vanadium provides a greater amount of more ductile

phase while vanadium provides a greater amount of more ductile

![]() phase during hot-working.

phase during hot-working.

Solute is said to be trapped when its chemical potential increases on

transfer across the moving interface. It occurs when the interface

velocity becomes comparable to the diffusion velocity ![]() wheere

wheere ![]() is the interatomic jump distance. Examples: rapid

solidification, martensitic transformation (C in Fe), paraequilibrium (Mn

in ferrite).

is the interatomic jump distance. Examples: rapid

solidification, martensitic transformation (C in Fe), paraequilibrium (Mn

in ferrite).

Martensitic transformation is diffusionless. Bainite grows without diffusion but because it forms at relatively high temperatures, the carbon can rapidly (a second or so) escape into the residual austenite. It may then precipitate as cementite, giving an upper bainite microstructure. If the bainite transformation temperature is reduced then the carbon escapes less rapidly so that it is possible for some of it to precipitate inside the ferrite plates, giving a lower bainite microstructure (Fig. 6.12, Honeycombe & Bhadeshia). Widmanstätten ferrite grows by a displacive paraequilibrium mechanism involving the diffusion of carbon. It thus grows at a rate which is controlled by the diffusion of carbon in the austenite ahead of the interface. Furthermore, there is little driving force available at the temperatures at which Widmanstätten ferrite grows so two plates have to grow together in a self-accommodating manner in order to reduce the overall strain energy. This is why it optically appears to be in the form of a thin wedge, since the component plates have slightly different habit planes.

Worked Examples 1-4

Worked Examples 5-13

Worked Examples 14-20

H.K.D.H. Bhadeshia