Gigacycle fatigue testing

H. K. D. H. Bhadeshia

Gigacycle fatigue tests

Rotating-bending fatigue machines can achieve loading frequencies of about 50Hz and servohydraulic testers some 400-1000 Hz. In contrast, piezoelectric devices are used to test smooth samples using axial loading or torsion, at frequencies in the range 20-100 kHz in order to reasonably rapidly achieve fatigue data up to 1011 cycles.

Testing in tension-compression involves keeping a constant displacement amplitude during the test. For most of the fatigue life there is little difference in specimen loading between stress and strain controlled experiments until the fatigue crack becomes large. The specimen in ultrasonic fatigue vibrates in resonance with the stimulus and the sample is designed so that the point half way along its length is a displacement node where the stress is maximum. Hour-glass shaped samples are normally used. Parallel gauge lengths may be introduced in order to increase the volume at risk, although the distribution of stress within that length will not be uniform. On the other hand, samples can be designed so that the variation of stress within the straight section is small.

Conventional tests for 1011 cycles would take more than a decade to complete, whereas with a 100 kHz ultrasonic machine, the test would be completed in less than 300 h. The samples can be notched in order to introduce stress concentrations. There are important factors to bear in mind with high frequency tests:

- It is understood that the temperature of the sample may increase by some 50°C due to anelastic dissipations within the material during the course of the tests done at the highest of frequencies; this may be avoided by specimen design and by cooling with gas or air.

- The ability of the material to respond to high frequency changes in loading may not be the same as at conventional frequencies. The characteristic distances through which dislocations move must clearly depend on the strain rate. The time available for hydrogen to effuse and diffuse will be a function the test duration. It has been demonstrated that fatigue crack growth rates in hydrogen charged specimens are sensitive to frequency even over the range 0.5-15Hz with faster crack growth rates at lower frequencies. For the same reason, corrosive environments have their most pronounced influence in accelerating crack growth when the growth rate is slow. Environmental effects in general introduce a frequency dependence of fatigue strength.

- Fatigue crack growth rates may be frequency dependent if hydrogen diffusion to the crack tip is a controlling feature.

- Early work indicates that the endurance limit goes through a maximum as a function of frequency.

- It is known that defects such as dislocations are able to relax more readily under the influence of ultrasonic loading at the frequencies discussed here.

- It has been demonstrated for artificial defects (100 μm circular holes) that neither the stress concentration nor the stress intensity factors change significantly when the test frequency is changed from 10Hz to 20 kHz. But it remains to be demonstrated whether these results extrapolate to the sharp defects associated with normal damage evolution.

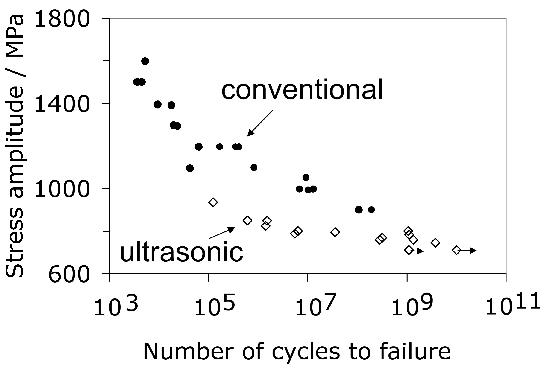

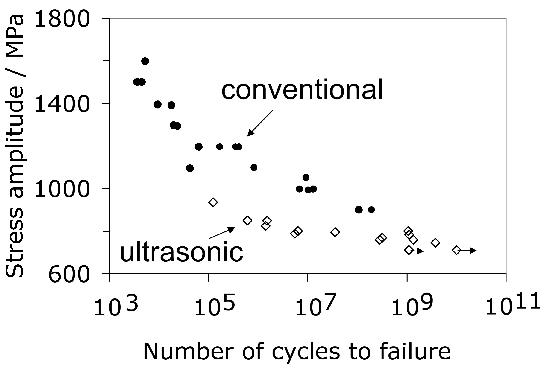

The plot below compares data obtained in a conventional test at 50 Hz and those measured using 20 kHz ultrasonic loading. The two sets deviate substantially at all stages of life where a comparison can be made.

More details are provided in a recent review. The images below shows the sort of samples used in gigacycle testing. The samples were prepared by Jae Yong Chae.

The sample before testing.

|

The sample before testing.

|

The sample before testing.

|

The sample following testing. Notice the heat mark in the highly stressed region.

|

The sample following testing. Notice the heat mark in the highly stressed region.

|

The sample following testing. Notice the heat mark in the highly stressed region.

|

The sample following testing. Notice the heat mark in the highly stressed region.

|