Coalesced martensite in pressure vessel steels

Hector Pous-Romero and H. K. D. H. Bhadeshia

Abstract

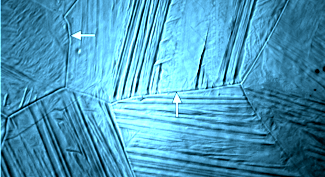

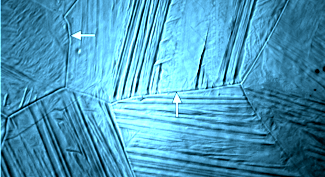

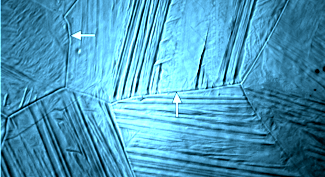

An alloy commonly used for large pressure vessels, known as SA508 Gr. 3, has a microstructure after heat treatment consisting of a mixture of tempered bainite and martensite at fast cooled regions near surfaces subject to water quenching. These two phases are conventionally recognised to consist of fine platelets, each of which is approximately 0.2 μm in thickness; enhancing strength and leading to good toughness properties.

We have discovered in our experimental work that there are circumstances where the adjacent platelets of a similar orientation can coalesce as the austenite transforms, to produce much coarser structures which are believed to be detrimental to toughness. An examination of published micrographs reveals that such coalesced regions existed but were not noticed in previous studies. The mechanism of coalescence is described and methods to ameliorate the coarsening are discussed.

Journal of Pressure Vessel Technology 136 (2014) 031402.

Download paper

Related papers

-

"Understanding Mechanical Properties of Novel High Strength Steel Weld Metals Through High-Resolution Microstructural Investigations"

Trends in Welding Research, ASM International, eds S. A. David, T. DebRoy, J. C. Lippold, H. B. Smart and J. M. Vitek, 2005, pp. 969-974.

E. Keehan, L. Karlsson, H. O. Andrén and H. K. D. H. Bhadeshia

-

"Coalesced Bainite"

Transactions of the Indian Institute of Metals, Vol. 59, 2006, pp. 689--694.

H. K. D. H. Bhadeshia, E. Keehan, L. Karlsson and H.-O. Andrén

-

"Microstructure of Lower Bainite formed at Large

Undercoolings Below the Bainite-Start Temperature"

Materials Science and Technology, Vol. 12, 1996, 233-236.

L. C. Chang and H. K. D. H. Bhadeshia

- "Three-dimensional analysis of coalesced bainite using focused

ion beam tomography"

Materials Characterisation, Vol. 59, 2008, 877-882.

E. Keehan, L. Karlsson, H. K. D. H. Bhadeshia and M. Thuvander

-

"EBSD of coalesced bainite in strong steel weld metals"

Materials Science and Technology, Vol. 24 (2008) 1183-1188.

E. Keehan, L. Karlsson, H. K. D. H. Bhadeshia and M. Thuvander

- "Promoting Coalesced Bainite"

Scripta Materialia 66 (2012) 951-953.

J. H. Pak, D. W. Suh and H. K. D. H. Bhadeshia

- "Three-dimensional analysis of coalesced bainite using focused

ion beam tomography"

Materials Characterisation, Vol. 59, 2008, 877-882.

E. Keehan, L. Karlsson, H. K. D. H. Bhadeshia and M. Thuvander

- "Mechanism of misorientation development within coalesced martensite"

Materials Science and Technology, 28 (2012) 918-923

J. H. Pak, H. K. D. H. Bhadeshia and L. Karlsson

-

"Coalesced Bainite"

Transactions of the Indian Institute of Metals, Vol. 59, 2006, pp. 689--694.

H. K. D. H. Bhadeshia, E. Keehan, L. Karlsson and H.-O. Andrén