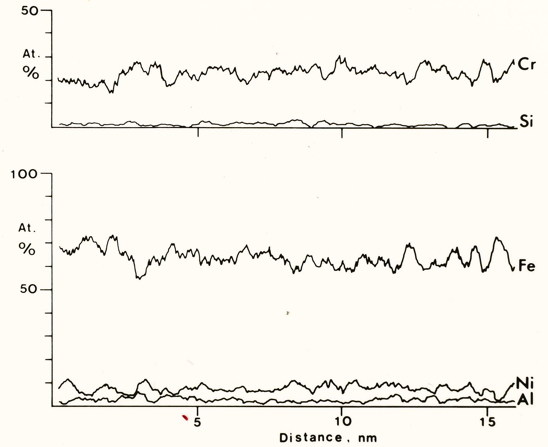

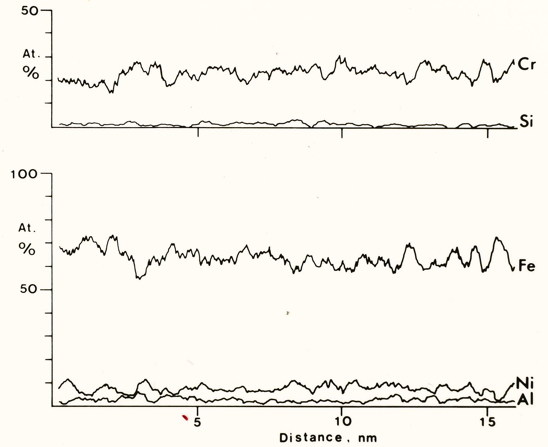

17-7 PH strainless steel, as drawn in the softened condition. Chemical composition profile as a function of depth, determined using the atom probe.

17-7 PH is a stainless steel that in its soft condition is mostly austenitic with some delta-ferrite. The chemical composition of the steel studied here is Fe-16.9Cr-7.02Ni-1.17Al-0.54Si-0.66Mn-0.074C wt%. It can then be heated to a temperature (750°C) where some of the chromium and carbon precipitates as M23C6, thus causing a substantial amount of the original austenite to transform into martensite. Subsequent tempering at 475°C leads to the formation of ordered NiAl with the resulting strengthening making the material suitable for corrosion resistance springs after cold drawing.

There are some more details available in the proceedings of Solid-solid phase transformations, 1981, p. 769.

Photographs courtesy of Dr Sally Waugh.

17-7 PH strainless steel, as drawn in the softened condition. Chemical composition profile as a function of depth, determined using the atom probe.

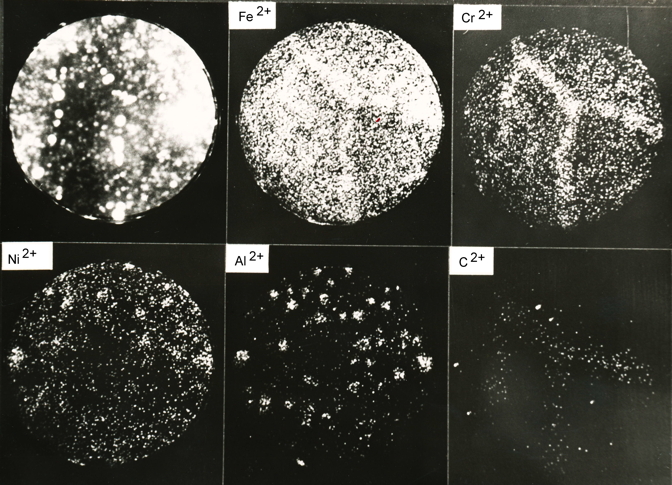

Atom probe field-ion micrographs after ageing the steel for 75 min at 475°C. There are early signs of NiAl precipitation together with M23C6. (additional images)

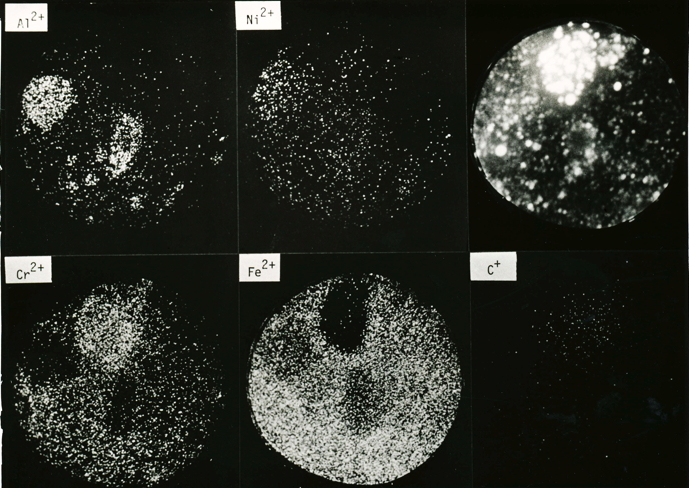

Atom probe field-ion micrographs after ageing the steel for 750 min at 475°C. The precipitates are larger and there There are early signs of NiAl precipitation together with a large M23C6 particle. (additional images)

Some random images from the stainless steel.

4th edition, 2017 |

Free download |

Free download |

| PT Group Home | Materials Algorithms |