A good literature survey covers the state-of-the-art, is a critical assessment and can define new work. It also helps avoid the repetition of research through ignorance.

As a part of your course, you are required to conduct such a survey on one of the topics listed below. The length should be about 3000 words, not including references. This survey must be completed during the Lent term, and your report submitted by Friday 17th March 2006 (the last day of term). Your report must be concise and well-written, with particular attention to referencing.

To help you, there is an example format of a survey which can be used as a guideline to the presentation style, although this should not restrict creativity. A list of common mistakes can also be studied. Examples of published surveys are available:

The survey will be assessed and can contribute 6% (report - 5%; presentation - 1%) towards your final mark for the whole course.

You may consult the originator of the topic to obtain two references to start the survey, and you can make reasonable use of that originator for advice throughout the exercise.

On the 17th of March 2006, 2.00 p.m., you are required to give a public presentation of your findings, to which all those involved in the Course will be invited. You may use a approximately six transparencies and will have 10 minutes including 2 minutes for questions. Guidelines on making presentations are also available.

It is likely that University Libraries, such as the Scientific Periodicals Library (SPL), will have to be used, in addition to the Department Library and it is your responsibility to ensure that you are registered with the main University Library, so that you can use other libraries around the University. A variety of on-line search facilities can be used; for information about accessing this, including usernames and passwords, see the Department Librarian).

You can also access the main University Library catalogue and the Web of Knowledge. You can get help on both of these from the Department Librarian.

Marks will be given in integers, out of 18, as follows:

Electrically conductive polymer matrix systems are gaining more importance in high-tech applications today, such as conductive textiles, Formula 1 racing cars and aerospace components. The recent discovery of novel carbon structures, such as carbon nanotubes (CNTs), is expected to introduce electrical conductivity to a polymer together with a desirable increase in mechanical performance, acting as tiny fibre reinforcements. Little is known about the percolation behaviour of atomic-scale filler particles with high aspect ratios (length to diameter ratios). Percolation describes the transition to a three-dimensional network of particles. The objective of this work is to develop an understanding of how the electrical properties of polymer-CNT composite are related to the geometry of the CNTs used, their orientation, and their packing fraction.

Supervisor: Dr James Elliott (jae1001@cam.ac.uk)

Demonstrator: Mr Sameer Rahatekar (sr347@cam.ac.uk)

|

|

| Fig. 1: CNT represented as a collection of fused spheres | Fig. 2: Mixture of fibres and spheres |

We use mesoscale modelling approach in which carbon nanotube is represented as collection of fused spheres as shown in Fig 1. The orientation of the assembly of the nanotube is then simulated using DL_POLY code. The conductivity of the CNT network is predicted by using in house Monte Carlo simulation code.

So far we have been able to predict the percolation network formation for randomly oriented nanotubes and partially oriented nanotubes using DL_POLY and Monte Carlo simulations. We would be interested in following possible directions

Knowledge of CERIUS, programming and DL_POLY would be useful but is not necessary. For further details please contact the supervisor Dr James Elliott (jae1001@cam.ac.uk) or Sameer (sr347@cam.ac.uk).

Supervisor: Dr Kevin Knowles, kmk10@cam.ac.uk

The purpose of this project is to predict the magnitude of the van der Waals interaction energy as a function of separation, L, between two slabs of bulk anistropic media such as rutile, TiO2, between which there is an isotropic medium. This interaction energy is usually expressed in terms of the so-called Hamaker constant, A. While equations exist in the literature for A for slabs for anisotropic materials in the non-retarded limit as L → 0, only one very specialised case has been solved in the technical literature for A for the more general case of finite L. This has been applied to graphite with various anisotropic media in between the two slabs of graphite. Thus, there is scope for first testing this very specialised case with rutile as the anisotropic medium before examining how the theory behind the equations can be extended to other geometries. The project will involve the writing of suitable code for either Fortran and/or Excel spreadsheets after examination of the relevant mathematics behind the equations. It will appeal to someone with a good mathematical background willing to apply this to a physical problem of interest in the colloid and interface science aspect of nanotechnology.Supervisor: Dr Paul Bristowe, pdb1000@cus.cam.ac.uk

Demonstrator: Johann von Pezold, jv255@cam.ac.uk

GaN is a wide band gap semiconductor used to make high frequency light emitting diodes, lasers and field-effect transistors. The device heterostructures contain metal contacts whose electrical resistance should be low. Suitable contacts have been designed for n-type GaN but problems have been encountered for p-type GaN. In this case the most commonly used contact is a Au/Ni/p-GaN structure which, when annealed in oxygen, has a reasonably low resistance. However, the reasons for this are not clear and if further progress is to be made a full theoretical understanding is required. One explanation is the formation of Ga vacancies in the p-type GaN which reduces the depletion region near the contact and hence lowers the resistance. The formation energy of these defects is thought to be high but could be reduced in the presence of Au or Ni atoms if these impurities diffuse into GaN at high temperatures. Atomic level modelling has a crucial role to play in understanding how the defect structure and chemistry of GaN influences its electrical properties. In an attempt to understand the mechanism underlying the low contact resistance of the Au/Ni/p-GaN structure, the formation energies and electronic properties of various point defect / impurity clusters in GaN will be studied using plane wave density functional theory, as implemented in the CASTEP code. The student will work in the Atomistic Simulation Group and the project will be linked to ongoing experimental investigations within the Cambridge GaN Research Centre.

Supervisor: Dr Paul Bristowe, pdb1000@cus.cam.ac.uk

Demonstrator: Helen Chappell, hc263@cam.ac.uk

Bone mineral is based on a form of calcium phosphate known as hydroxyapatite (HA) which has the chemical formula Ca10(PO4)6(OH)6. However, in its biological environment the HA reacts with surrounding fluids and adsorbs other chemical species such as CO32-, HPO42-, Na+M, Mg2+, K+, Cl- and F-. These species substitute for various ions in the lattice and can also induce the formation of vacancies such as missing hydroxyl groups. Bone mineral is therefore characterised as a non-stoichiometric, calcium deficient carbonate apatite. The substituted ions are important and play various roles including affecting the dissolution rate of the mineral. It is now possible synthesise HA in the laboratory and this opens up the possibility of using artificial bone mineral to replace real bone mineral which has become damaged or diseased. Preparing artificial HA, however, is not straightforward because of its complex chemistry and it is therefore important to know what effect each ionic substitution is having on the structure and energy of the lattice. Atomic level modelling can help in this regard by making predictions about new substitutions as well as explaining existing observations on material already synthesised. This project will focus on carbonate substitution which is known to replace the phosphate group. Formation energies will be calculated for different configurations and if time permits the substitution of a second species will be investigated. The student will work in the Atomistic Simulation Group and the project will be linked to ongoing experimental studies within the Cambridge Centre for Medical Materials. The calculations will be performed on the Cambridge High Performance Computing Facility using the density functional plane-wave code CASTEP.

Supervisor: Mark Blamire mb52@cam.ac.uk

Controlling the exchange interaction between ferromagnet (FM) and antiferromagnet (AF) layers is fundamental to the operation of devices based on spin electronics. In contrast to the polycrystalline AFs used in production devices, the exchange interaction in epitaxial AFs is dependent on the relative orientation of the applied field and the AF spins, and so provides a means understand at a fundamental level the directional dependences of exchange bias and enhanced coercivity seen in exchange biased systems. The aim of this project is to investigate the magnetic reversal process of an isotropic ferromagnet coupled to specific AF spin orientations and to compare the results with recent experimental results obtained in the Department.

Supervisors: Zoe Barber, zb10@cam.ac.uk and Mary Vickers, mev20@hermes.cam.ac.uk

X-ray mirrors are fabricated by thin film deposition of light element / heavy element multilayers: Bragg diffraction from such periodic coatings effectively leads to ‘reflection’ of radiation with wavelengths similar to the periodicity. At very short X-ray wavelengths (e.g. < about 4 nm; i.e. energies > about 0.3 keV) efficient normal incidence multilayers are not yet possible because of interface imperfections between the layers (roughness and/or interdiffusion), but periodic multilayers can still be used near grazing incidence to provide high reflectance. However, periodic multilayers provide high reflectance only over a narrow range of wavelength. In contrast, depth graded multilayers, in which the individual layer thicknesses vary with depth, can provide broadband X-ray reflectance. This technology is finding applications in hard X-ray/ soft gamma-ray telescopes and in X-ray diffraction techniques.

Colleagues at the MRC Laboratory of Molecular Biology are interested in the fabrication of a versatile collimator for X-rays from a microfocus X-ray tube. The design suggested uses an ellipsoidal mirror with an internal surface which is coated with a depth-graded multilayer. The depth grading in the multilayer must be calculated to give the appropriate function of reflectivity as a function of angle of incidence.

Various software models exist for calculating the reflectance as a function of wavelength for depth graded multilayers, and these can be used to predict the necessary multilayer spacings for this particular application. However, such models begin with the assumption of ‘perfect’ multilayers with sharp interfaces. In a previous (experimental) project W/Si multilayers have been fabricated by sputter deposition, and their X-ray reflectivity has been characterised and compared with predictions from the models.

This project will require application of existing models, and the further development of such models in order to bring them closer to predicting the characteristics of real multilayers. There is a need to understand the imperfections in such multilayers and their origins (dependent upon the deposition techniques used) in order to optimise the design and fabrication of this collimator.

Supervisor: Professor Harry Bhadeshia, hkdb@cus.cam.ac.uk and Richard Kemp rk237@hermes.cam.ac.uk

The equations for configurational entropy as used in the ideal and regular solution models depend only on the number of entities present in the system, whether these entities are particles of arbitrary size or atoms.

In this project we will introduce a physical dimension (i.e. 1 for lines, 2 for areas and 3 for volumes) to derive differences in the configurational entropy of ropes, sheets and volumes of materials.

This is important because there are many ill-conceived claims about the strength of materials which are based on perfection. For example, the space elevator project, which relies on perfection in tubes of carbon. It has recently been shown that this is impossible to achieve, even in principle. But a quantitative demonstration requires a consideration of material dimensions.

The thermodynamic approach we shall use deals with equilibrium. It is possible to argue that perfect materials can be created in a non-equilibrium state. One part of the project will deal with a model to predict the probability of reaching perfection as a function of size.

Finally, an attempt will be made to assess the safe use of strong materials in terms of the stored energy and the rate at which it is dissipated during fracture.

To create a model for entropy as a function of dimensions we shall consider higher order entities than atoms. The thermodynamics lectures of the M.Phil. course form a firm foundation for this project. Once the problem is solved, we shall apply it to engineering structures as well as the issues addressed above.

|

| Space elevator concept (Arthur C. Clark, 1979) |

Supervisor: Professor Harry Bhadeshia, hkdb@cus.cam.ac.uk and Dr Howard Stone, Howard.J.Stone@umist.ac.uk

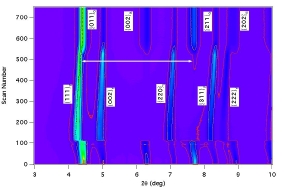

We have recently conducted some amazing experiments using the synchrotron at Grenoble. In this experiments, we placed a thermomechanical simulator inside a beam of high intensity X-ray. This enabled full X-ray diffraction patterns to be collected at millisecond intervals, thus revealing the progress of the bainite reaction in real time.

The purpose of this project is to convert the recorded intensities from the X-ray data into the mass fractions of the parent and product phases, and then to compare the kinetics of the reaction against a recent theory (Matsuda and Bhadeshia, Proceedings of the Royal Society of London - A 460 (2004) 1710-1722.). The theory contains explict nucleation and growth functions which have in the past been deduced indirectly. The synchrotron data will enable a rigorous test of the model.

The particular alloy to be studied is quite novel. It transforms at an incredibly low homologous temperature, thereby resulting in a microstructural scale which is of the order of 20 nm. Unlike other materials which claim similar microstructures, this alloy can achieve https://www.phase-trans.msm.cam.ac.uk/2004/chunks.html). The work is therefore of technological and scientific interest.

|

| Synchrotron data from novel bainite |

Supervisor: Dr Rafal Dunin-Borkowski, rafal.db@msm.cam.ac.uk

Magnetite (Fe3O4) is the most abundant magnetic mineral in nature. Nanocrystals of magnetite are responsible for the magnetic properties of naturally occurring minerals, as well as for the ability of many organisms to navigate in the earth's magnetic field. The crystals are usually faceted and have sizes of between 5 and 200 nm, and their orientations and spacings determine the bulk magnetic properties of the mineral or organism. During this project, commercial micromagnetic simulation software will be used to study the effect of the shapes, sizes, orientations and spacings of small magnetite crystals on their response to an external magnetic field. Both remanent states and magnetization reversal processes will be studied in detail, and the results will be compared with experimental magnetic induction measurements obtained from a variety of materials using electron holography.

Supervisors: Dr Hugh Shercliff (hrs@eng.cam.ac.uk) and Dr Paul Colegrove (Engineering Department)

Friction stir welding (FSW) is a solid-state joining process invented a decade ago at TWI, primarily for Al alloys. It rapidly reached commercial application in shipbuilding with medium strength alloys, and is now under investigation for aerospace application in the highest strength heat- treatable alloys. These alloys derive their strength from precipitation hardening, and the passage of the welding tool causes a variety of effects on microstructure and properties.

As in conventional arc welding, the thermal cycle causes precipitate dissolution or coarsening, followed by some strength recovery by natural ageing, where there is residual solute available. In friction stir there is the added complication of two deformation zones - the weld nugget, where intense deformation takes place during joining, and a surrounding thermomechanically affected zone, where the strain is lower, but the material is less hot. In both areas the post-weld precipitation may interact with the higher dislocation density - affecting strength, or (more seriously) fatigue, toughness and corrosion.

Work is in progress in collaboration with Airbus UK and the University of Manchester to develop detailed process and microstructure models for FSW of aerospace Al alloys. This project could pursue a number of different aspects of the problem: - running a computational fluid dynamics (CFD) package, to predict thermal and deformation histories in selected test welds - conducting isothermal softening and natural ageing experiments on 2000 or 7000 series Al alloys, as input data to property prediction models - developing simple hardness models calibrated to isothermal data, and coupling these to the weld thermal histories to predict the hardness profile (using both microstructurally-based models, and direct statistical analyses of the isothermal hardness data) - exploring the refinements needed to the Manchester weld precipitation model to capture problems such as post-weld natural ageing, precipitate-dislocation interactions, and microstructure-property relationships.

Page created by Harry Bhadeshia and Zoe Barber, Last updated September 2005

|

|