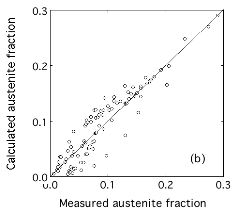

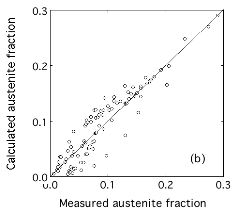

Fig. 1b, Sherif et al. 2004, eqn 3.

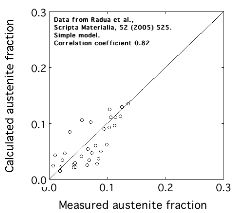

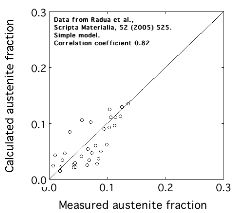

Analysis of Radu et al. (2005) data using equation 3 of Sherif et al.

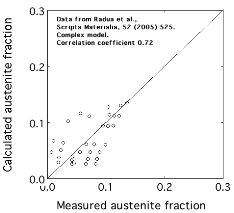

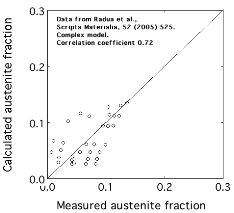

Analysis of Radu et al. (2005) data using equation 5 of Sherif et al.

A theory is developed for the quantitative representation of the strain--induced transformation of retained austenite in low-alloy, TRIP-assisted steels of the type developed for the automobile industry. It is possible therefore, to calculate the fraction of austenite as a function of the plastic strain, chemical composition, deformation temperature and the starting amount of austenite. The effect of composition and temperature is expressed through the free energy available for transformation. Good agreement has been obtained with published experimental data.The model can be used to investigate the stability of the austenite during plastic deformation.

Materials Science and Technology Vol. 20, 2004, 319-322

Download PDF file of paper, Download high-resolution figures.

Download complete textbook (free)

Radu et al. have recently published new data on the decomposition of retained austenite in TRIP-assisted steels as a function of the applied tensile strain in uniaxial experiments. M. Radu, J. Valya, A.F. Gourgues, F. Le Strat and A. Pineau: Scripta Materialia, 52 (2005) 525-530.

The carbon content in the retained austenite was not measured and hence has been calculated here assuming conservation of mass and a concentration of carbon in the ferrite of 0.03 wt%. The initial fraction of austenite was 0.136 and the average carbon concentration of the steel was 0.19 wt%.

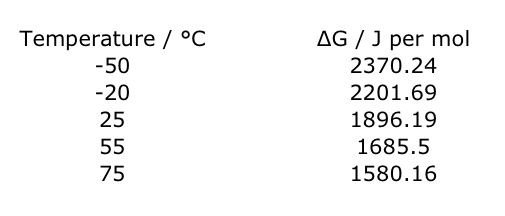

We have applied the Sherif et al. model to these new data; the results are illustrated below, alongside the original plot. The absolute values of the chemical driving force, calculated using MTDATA, are show in the table below; the change in free energy on the formation of martensite is of course negative.

Fig. 1b, Sherif et al. 2004, eqn 3. |

Analysis of Radu et al. (2005) data using equation 3 of Sherif et al. |

Analysis of Radu et al. (2005) data using equation 5 of Sherif et al. |

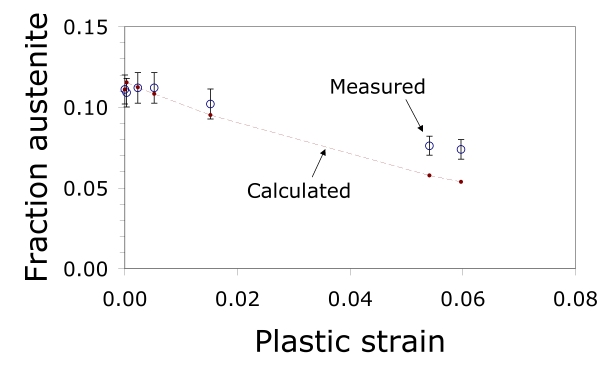

Zhao et al. have recently published new data on the decomposition of retained austenite in TRIP-assisted steels as a function of the applied tensile strain in uniaxial experiments. L. Zhao, N. M. van der Pers, J. Sietsma, S. van der Zwaag: Materials Science Forum, 500-501 (2005) 379--386. The chemical composition of the TRIP-assisted steel was Fe-0.17C-1.46Mn-0.26Si-0.01P-1.81Al wt%.

After transformation, the carbon concentration of the retained austenite was 0.93 wt%, the value used in the calculations below. This corresponds to ΔG of 2883 J mol-1 calculated using MTDATA.

In the figure below, the calculations use equation 3 of Sherif et al. and the data are from Zhao and co-workers.

|

| PT Group Home | Materials Algorithms |

|

|