Professor Dr. Bruno Buchmayer in his office at the University of Leoben

Special samples for formability tests

The latest Gleeble machine

The city of Leoben is quite spacious and beautiful. The University itself is about 3000 strong and the city has a population of just 25,000

The mushroom building

The mushroom building

Nice buildings

This particular building was made in the 17th century

A theatre

Metallurgy rules

This used to be a monastery, followed by a prison, and now a restaurant and shopping centre.

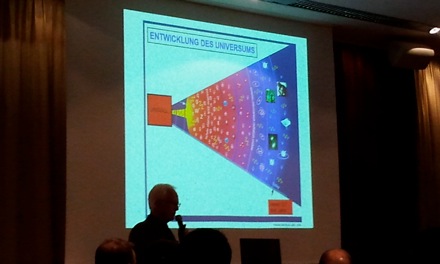

A meeting of the Austrian Society for Metallurgy

Award presentation cermonies and a nice dinner

The after-dinner speech was on the Big Bang, and how metals came about

The dark age of the Universe was 3000 years after the Big Bang, when there was only hydrogen and helium in abundance, so no stars to light the Universe. The heavier elements beyond lithium formed in the stars. The hot earth when it formed had most of its metals in the core, but heavy bombardment by meteors brought some of these to the surface.

Harry's hotel

The view from the hotel

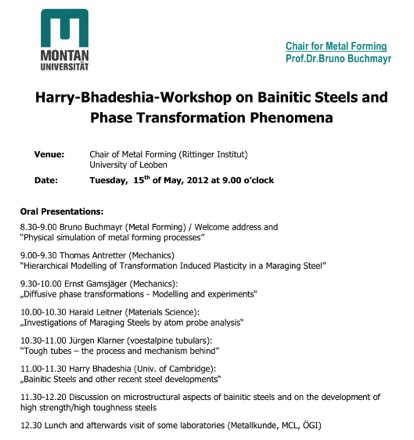

The workshop begins

A beautiful, sunny day

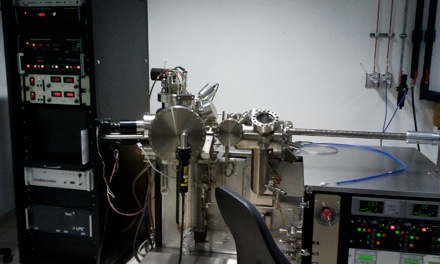

Harald Leitner and the LEAP atom probe

An Oxford Instruments atom probe

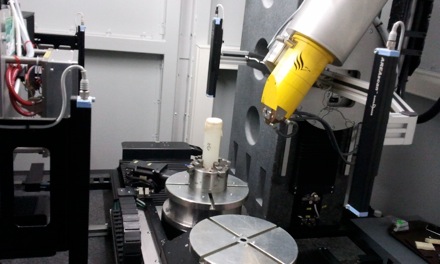

A high-temperature pin-on-disc abrasive wear machine

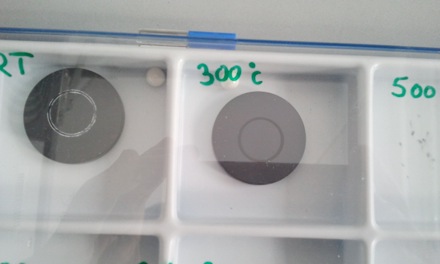

Wear tracks apparent on these samples

Peter Schumacher and his wonderful casting facilities. Peter Did his Ph.D. in Cambridge Unviersity with Lindsay Greer

X-ray tomography

A rotating-bending fatigue testing machine

A rotating-bending fatigue testing machine

The Rittinger Institute where Professor Buchmayer organised the workshop

An old iron-making furnace

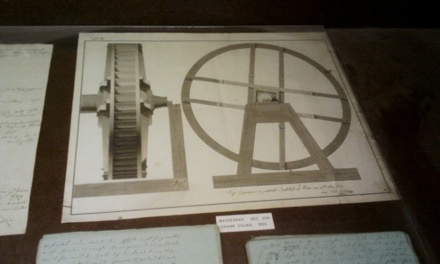

Water wheel used to drive a forge

Leoben and its surroundsing are breathtakingly beautiful

The turbulence created by placing logs in the lake introduces oxygen for the fish

A quiet, serene place for utter relaxation

The iron mountain, where ore has been mined for centuries and still continues to be productive

The iron mountain, where ore has been mined for centuries and still continues to be productive

The iron mountain

The iron mountain

This is where steel was made, starting about 1810. This is one of the locomotives which brought the ore from the iron mountain to this location

This is where the ore was preheated

We are now inside the blast furnace

This is the stretcher which was used to carry injured workers

This is the balcony designed to allow the workers to grab some fresh air

Water wheel

The water wheel which drives the bellows

These are bellows driven by the water wheel, to feed the tuyeres

Here the furnce was tapped

.. to form a layer of iron on the ground, which was then broken into bits and sent for forging

Another set of bellows

An anvil

A modern, Voest Alpine blast furnace

Blast furnace