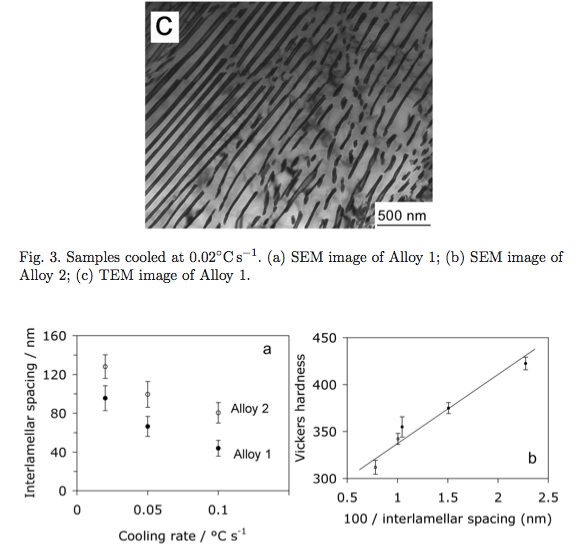

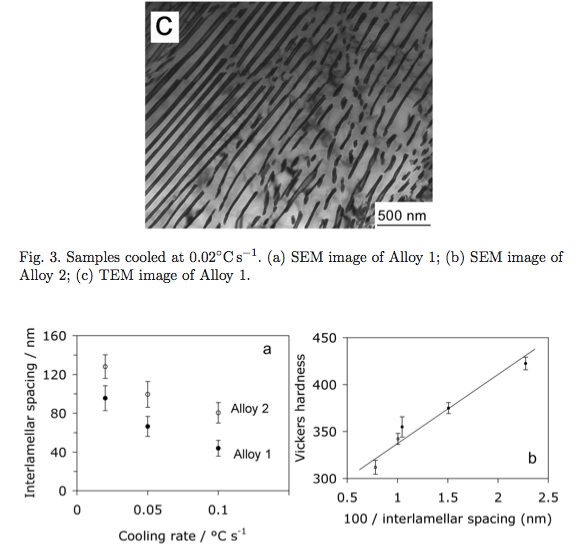

An extremely fine, fully pearlitic structure with an interlamellar spacing of 30-50 nm has been obtained during continuous cooling transformation at a rate as low as 0.1 °C s−1, of the steel that is normally used to produce nanostructured bainite. The solutes cobalt and aluminium have been added to accelerate the rate of reaction and reduce the interlamellar spacing by increasing the free energy of transformation. The range of cooling rates over which the fully pearlitic state can be achieved is characterized.

Scripta Materialia 67 (2012) 53-56

| Envelope | Coefficients | Filling welds | Hot | Delta |

| Satoh | Fields | Piping | European welds | Poles |

| Mixed | Creep | Extraordinary ductility | Problems | Mechanical stabilisation |

| PT Group Home | Materials Algorithms |