1st, 2nd and 3rd Generation Single-Crystal Nickel Based Superalloys

H. K. D. H. Bhadeshia

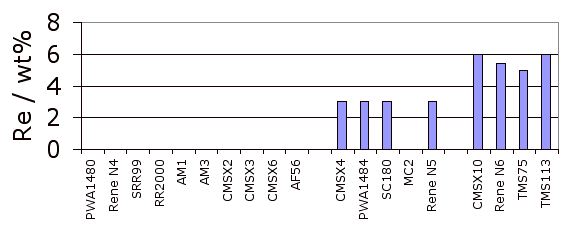

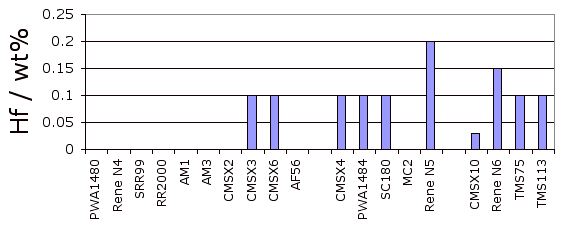

The single-crystal superalloys are often classified into first, second and third generation alloys. The second and third generations contain about 3 wt% and 6wt% of rhenium respectively. Rhenium is a very expensive addition but leads to an improvement in the creep strength and fatigue resistance. It is argued that some of the enhanced resistance to creep comes from the promotion of rafting by rhenium, which partitions into the γ and makes the lattice misfit more negative. Atomic resolution experiments have shown that the Re occurs as clusters in the γ phase. It is also claimed that rhenium reduces the overall diffusion rate in nickel based superalloys.

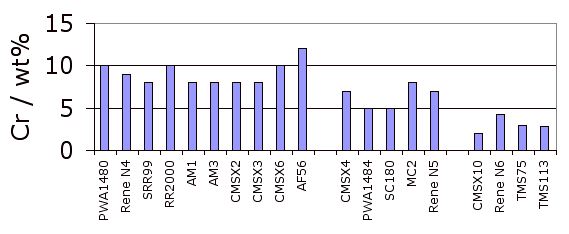

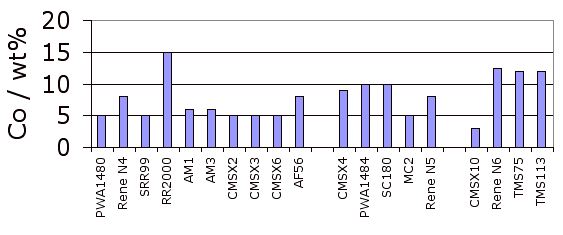

The properties of superalloys deteriorate if certain phases known as the topologically close-packed (TCP) phases precipitate. In these phases, some of the atoms are arranged as in nickel, where the close-packed planes are stacked in the sequence ...ABCABC.. However, although this sequence is maintained in the TCP phases, the atoms are not close-packed, hence the adjective 'topologically'. TCP phases include σ μ. Such phases are not only intrinsically brittle but their precipitation also depletes the matrix from valuable elements which are added for different purposes. The addition of rhenium promotes TCP formation, so alloys containing these solutes must have their Cr, Co, W or Mo. concentrations reduced to compensate. It is generally not practical to remove all these elements, but the chromium concentration in the new generation superalloys is much reduced. Chromium does protect against oxidation, but oxidation can also be prevented by coating the blades.

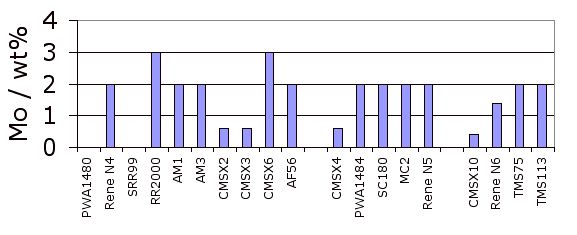

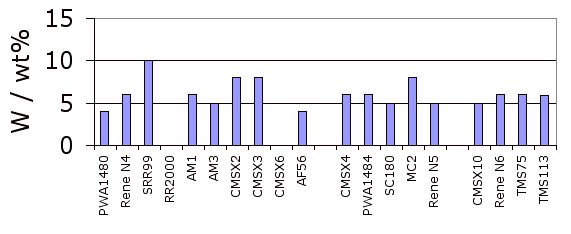

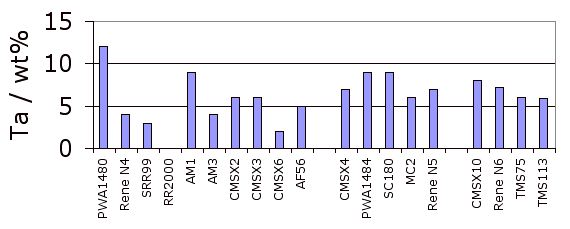

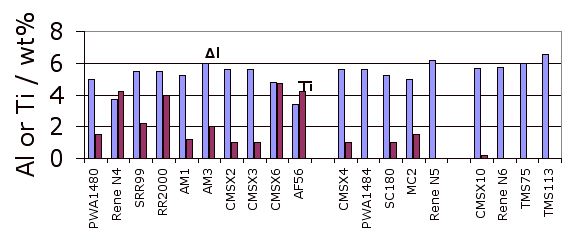

Single-Crystal Superalloys, nominal compositions (wt%). Adapted from Erikson, 1996.

|

The bars charts below show the essential compositional differences between the first, second and third generation single-crystal superalloys. The generations are separated by gaps in the horizontal axes.

References

- G. L. Erikson, Superalloys 1996, eds Kissinger et al., TMS-AIME, p. 35.