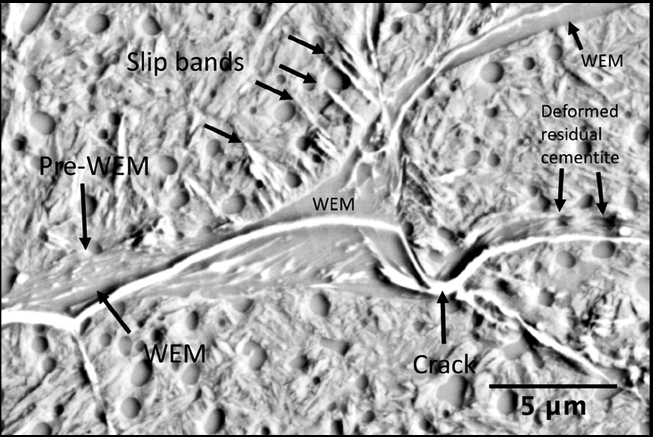

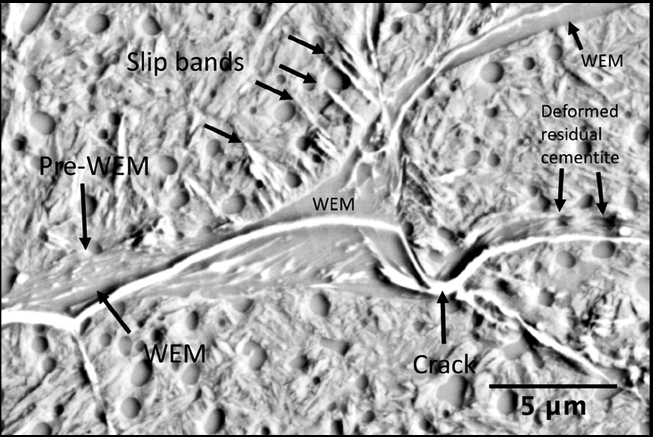

The effect of hydrogen and contact pressure on the sequence of microstructural changes during bearing operation has been investigated. The continuation of bearing testing in the presence of microcracks stimulates the formation of (1) white-etching matter (WEM) on the crack surfaces that endure severe surface rubbing, (2) slip bands in the region that experience a higher stress levels due to microcrack formation, and (3) engineering bands within the WEM. Engineering bands are a new observation whereby ferrite crystals cross a multitude of fine grains (WEM). The presence of hydrogen and high contact pressure during the bearing tests promoted early bearing failure, but with the formation of large crack networks, that coexist with slip bands, precursors to WEM, and conventional WEM.

Materials Science and Technology, 33 (2017) DOI: 10.1080/02670836.2017.1310431

| PT Group Home | Materials Algorithms |