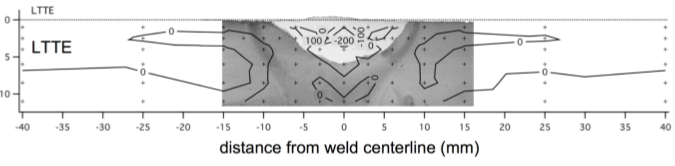

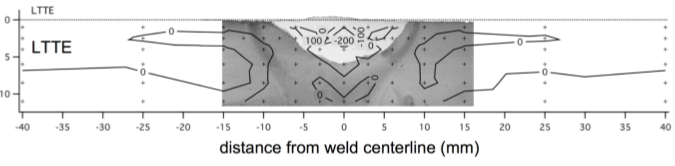

Residual stress in the vicinity of a weld can have a large influence on structural integrity. Here the extent to which the martensite-start temperature of the weld filler metal can be adjusted to engineer the residual stress distribution in a bainitic-martensitic steel weld has been investigated. Three single-pass groove welds were deposited by manual-metal-arc welding on 12mm thick steel plates using filler metals designed to have different martensite-start temperatures. Their longitudinal, transverse and normal residual stress distributions were then characterised across the weld cross-section by neutron diffraction. It was found that tensile stresses along the welding direction can be reduced or even replaced with compressive stresses if the transformation temperature is lowered sufficiently. The results are interpreted in the context of designing better welding consumables.

Journal of Pressure Vessel Technology, Vol. 131, 2009, 041401

| CML Home | Materials Algorithms |