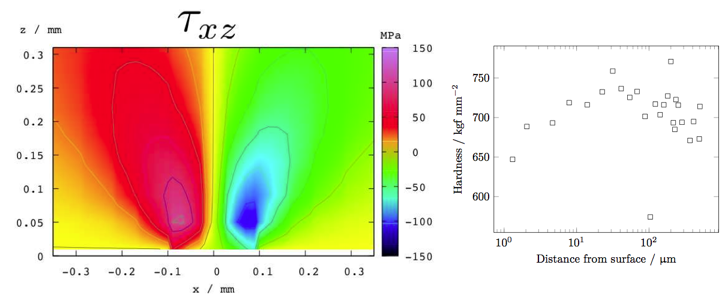

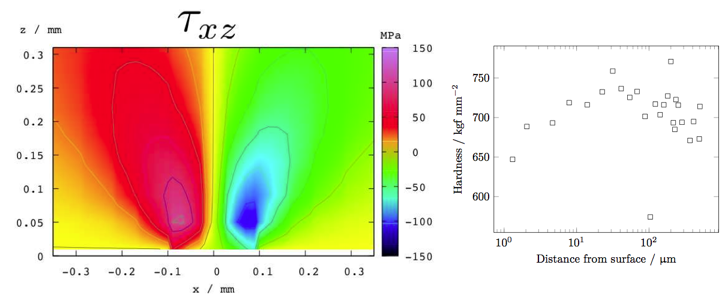

Simulation of rolling contact together with sliding, in this case leading to stresses that are a maximum below the contact surface, and cause maximum hardening also below the surface.

The abrasive wear of carbide-free bainitic steel under dry rolling/sliding conditions has been studied. It is demonstrated that this nanostructure, generated by isothermal transformation at 200°C, has a resistance to wear that supersedes that of other carbide-free bainitic steels transformed at higher temperatures. The experimental results, in combination with a theoretical analysis of rolling/sliding indicates that under the conditions studied, the role of sliding is minimal, so that the maximum shear stresses during contact are generated below the contact surface. Thus, the hardness following testing is found to reach a maximum below the contact surface. The fine scale and associated strength of the structure combats wear during the running-in period, but the volume fraction, stability and morphology of retained austenite plays a significant role during wear, by work-hardening the surface through phase transformation into very hard martensite.

Wear 316 (2014) 70-78.

Download paper on abrasive wear

Simulation of rolling contact together with sliding, in this case leading to stresses that are a maximum below the contact surface, and cause maximum hardening also below the surface.

| PT Group Home | Materials Algorithms |