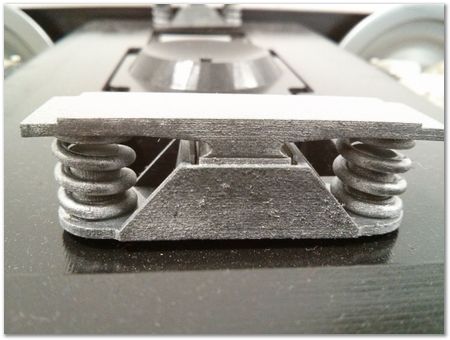

A amazing device made using laser powder bed fusion.

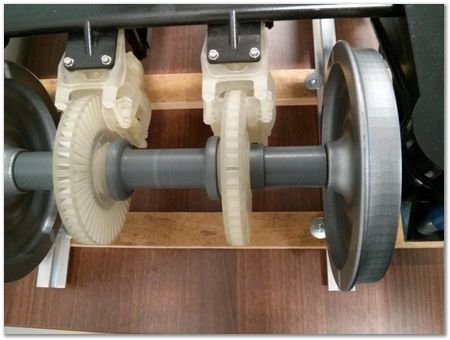

3D-printed Rail Bogey, Huddersfield University. A "bogey" is a module with wheels, that is then attached to a carraige. Everything on this bogey other than a few small screws, has been printed. The scale model is to show a new prototype of a bogey intended for freight traffic. Reproduced with the permission of Dr Adam Bevan or Huddersfield University.

The bearing illustrated below is made of plastic which has been built up by three-dimensional printing. This includes the balls, which have not been assembled after fabrication of rings, but rather, in situ. The bearing belongs to Tony Glendhill.

|

|

|

|

|

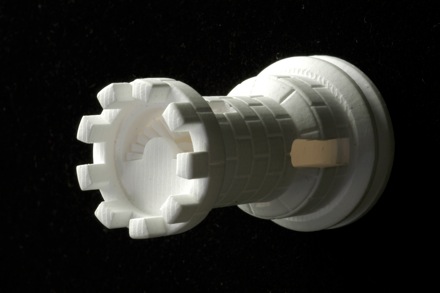

This chess piece has been made by sequentially depositing two-dimensional layers. It contains an internal staircase and other features which cannot be made by casting or moulding a three dimensional object.

|

|

|

|

|

|

|

|

|

|

|

|

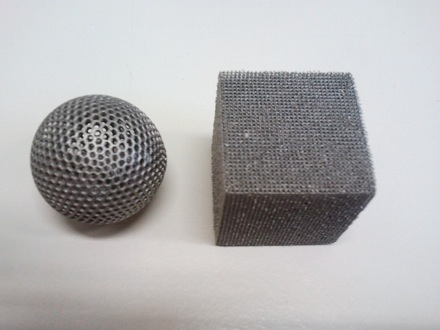

They are made by printing, i.e., building up three-dimensional forms layer-by-layer |

|

|

|

|

|

This is a device for allowing bone growth |

Mobius component made using three-dimensional printing. |

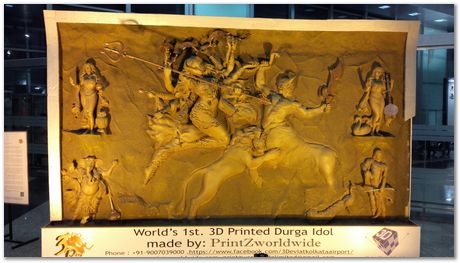

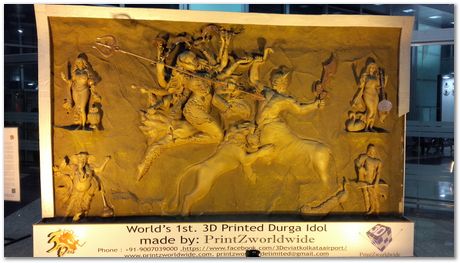

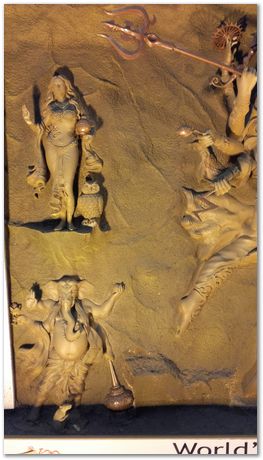

An amazing three-dimensional print of a scene from the epic scriptures, made of paper. |

|

On display at the airport in Kolkatta |

Involved the assembly of 13 million polygons |

|

|

| PT Group Home | Materials Algorithms |