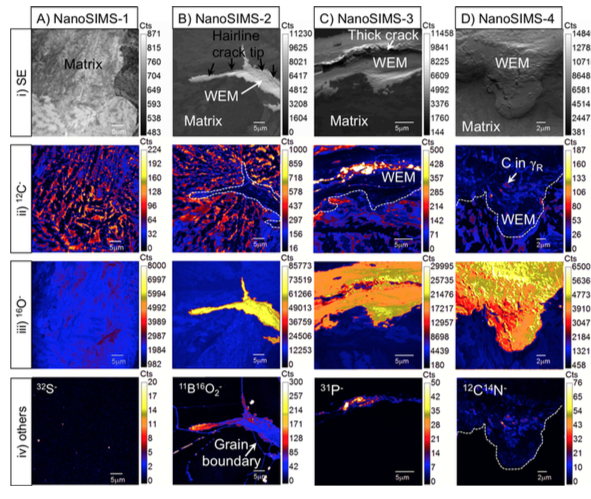

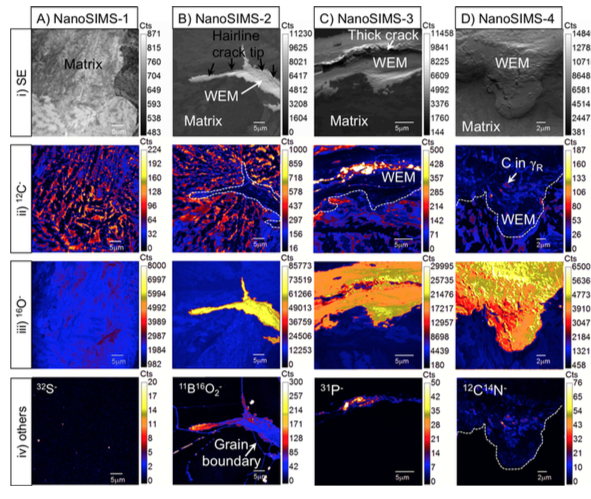

There has been a great deal of work on the formation of hard white-etching regions in conventional bearing steels such as 1C-1.5Cr wt% when subjected repeatedly to rolling contact stresses. The regions are a consequence of localised mechanical attrition across microcrack faces and mixing, which refine the local structure and force cementite to dissolve. This white-etching matter is often associated with brittle phenomena because the hardness can exceed 1100 HV. In contrast, carbide-free mixtures of bainitic ferrite and retained austenite when subjected to the same loading have been unexpectedly found not to develop the characteristic patches of hard material and to show instead signs of ductility in the attrited regions. The work presented here shows that the white-etching areas that develop in carbide-free bainite are softer than their surroundings, whether they are in hard nanostructured bainite destined for bearing applications or when the steel is designed for the manufacture of rails. Advanced characterisation tools were used for the first time to understand carbon redistribution during its formation. The deep interest about soft white-etching matter originates from the idea that it could lead to the reduction in premature failure of wind turbine gearbox bearings and white-etching layer grinding of rails.

Acta Materialia, 121 (2016) 215–226

| PT Group Home | Materials Algorithms |