Bags of granite used for wear testing

Bags of granite used for wear testing

Apparao's samples

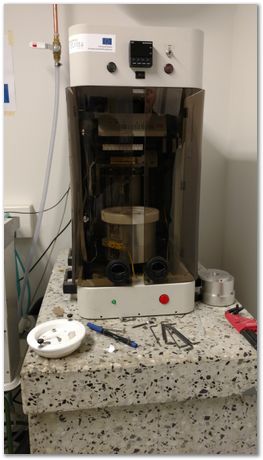

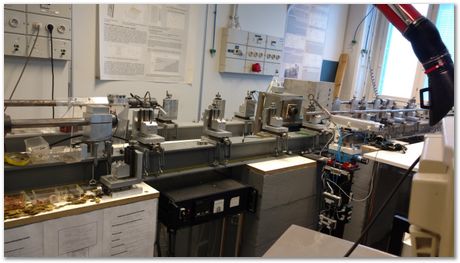

Dry pot wear tester

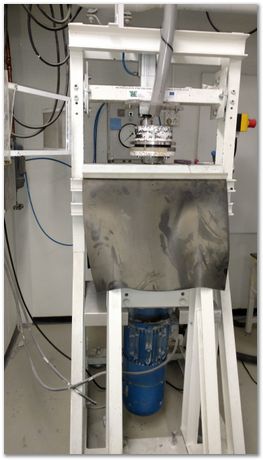

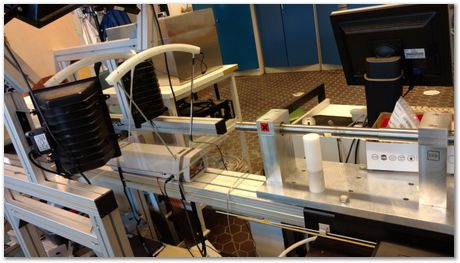

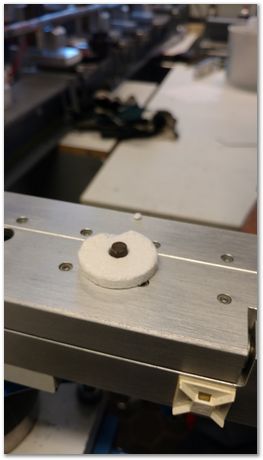

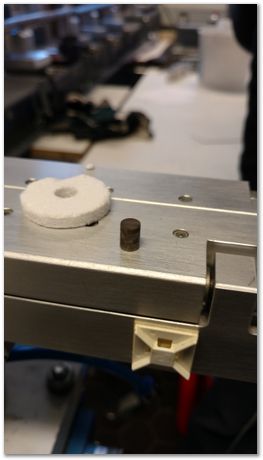

Pin-on-disc tester

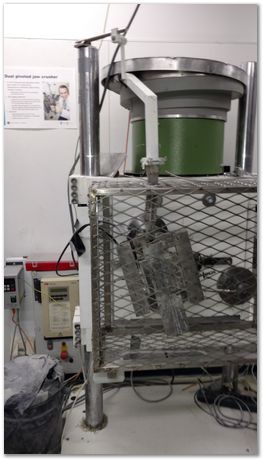

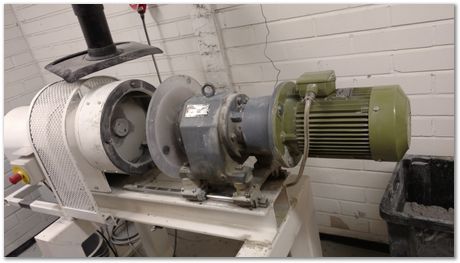

Jaw crusher

Jaw crusher

Pin-on-disc machine

Granite for impeller-tumbler test, before and after completing the test.

Iron balls for impact wear tests

Granite for impeller-tumbler test, before and after completing the test.

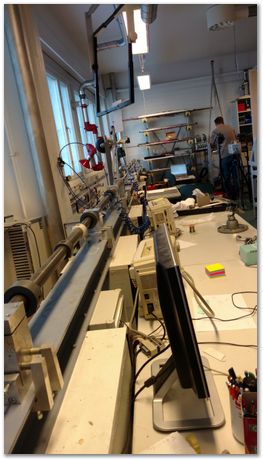

Tumbler of impeller-tumbler test machine

impeller-tumbler test machine

impeller-tumbler test machine

Dry pot test machine

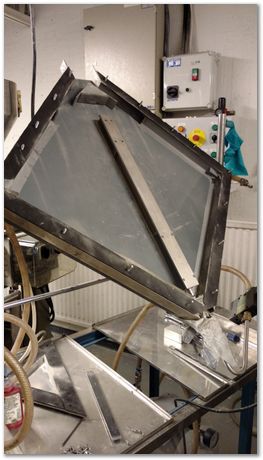

Dry sand, three-body abrasion test

Dry sand, three-body abrasion test

Dry sand, three-body abrasion test

Erosion tester

Hammer mill type impact wear testing device

Hammer mill type impact wear testing device

High velocity particle impactor

High velocity particle impactor

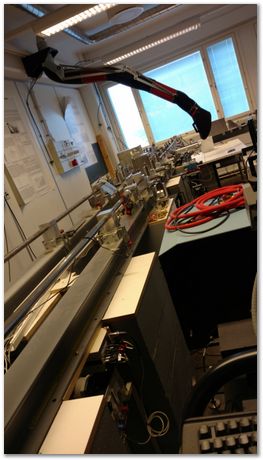

High strain-rate tensile tester

sample for high strain-rate tensile test

High strain-rate compression tester

Testing drop-resistance of mobile telephones

Professor Veli-Tapani Kuokkala

impeller-tumbler test with mounted samples from Apparao

Three dimensionally printed chocolates

Three dimensionally printed chocolates

Professor Veli-Tapani Kuokkala, Kati Valtonen and Apparao, at Lapland Hotel