Spheroidisation of Pearlite

H. K. D. H. Bhadeshia

Spheroidisation is a heat treatment carried out on steels containing pearlite in order to induce the cementite lamallae to change into spherical shapes. The heat treatment is carried out at a temperature which is below that required to generate austenite, i.e., just below the Ae1 temperature. The higher the spheroidisation temperature, the faster is the process.

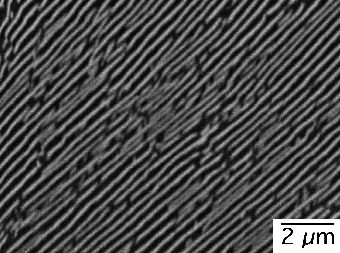

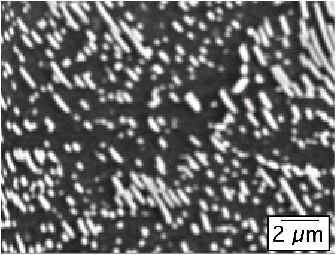

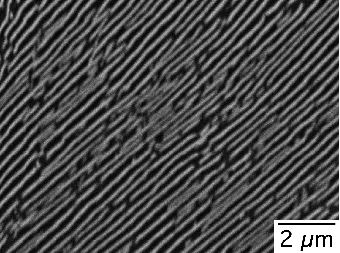

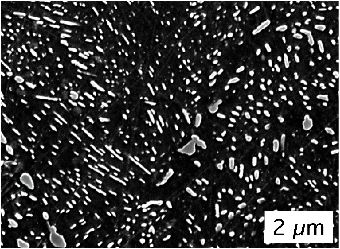

The spheroidisation of cementite is driven by the minimisation of ferrite/cementite interfacial area per unit volume. It follows that the rate of spheroidisation is greater when the initial microstructure is finer (greater interfacial area per unit volume). The micrographs below illustrate this. Further details can be found in the associated paper and slide presentation which follow the images.

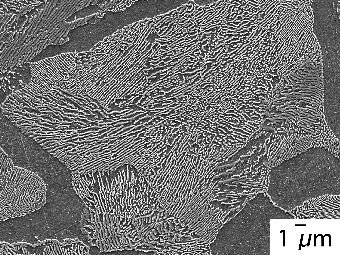

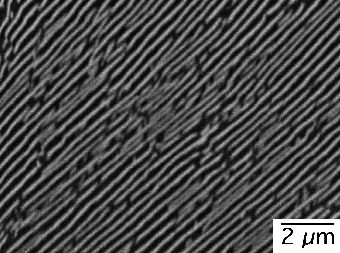

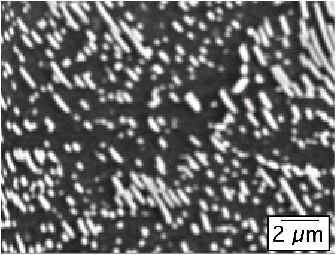

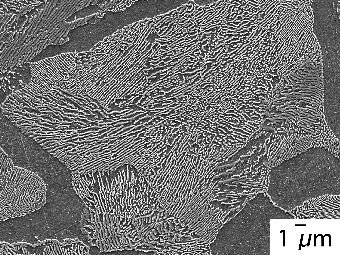

Pearlite with 0.24 micrometers interlamellar spacing |

After spheroidisation for 1.5 h at 750 centigrade |

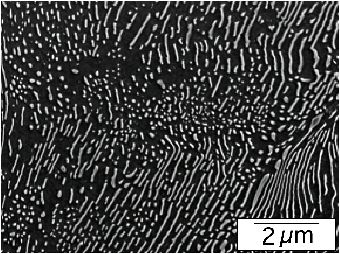

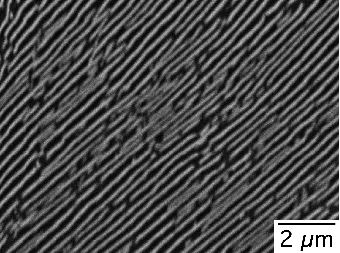

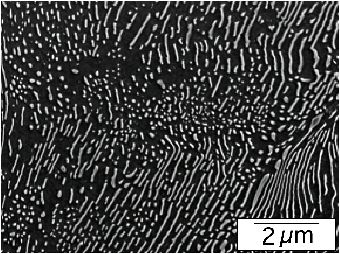

Pearlite with 0.17 micrometers interlamellar spacing |

After spheroidisation for 1.5 h at 750 centigrade |

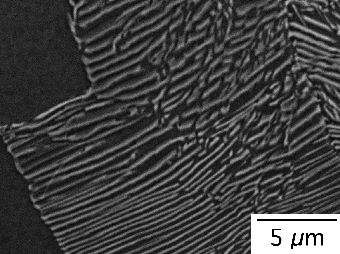

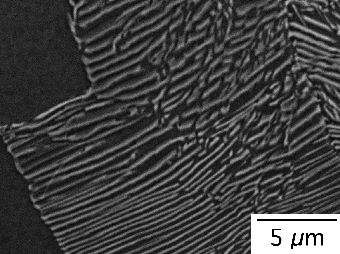

Pearlite with 0.23 micrometers interlamellar spacing |

After spheroidisation for 1.5 h at 750 centigrade |

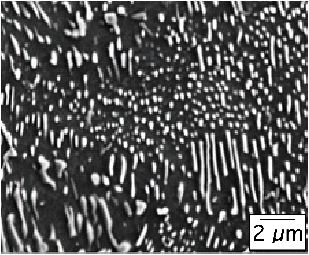

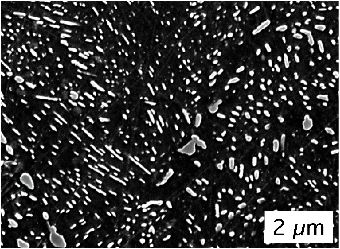

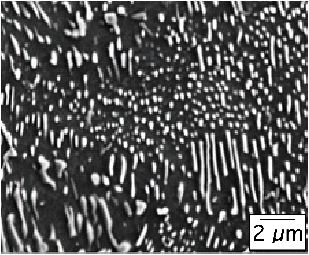

Pearlite with 0.13 micrometers interlamellar spacing |

After spheroidisation for 1.5 h at 750 centigrade |

Paper and Presentation

Acknowledgment

The micrographs have been kindly been provided by Dr Carlos Capdevila from a presentation by J.P. Ferrer, C. Capdevila, F.G. Caballero and C. García de Andres, of CENIM/CSIC, Madrid, Spain.