Ausforming of medium carbon steel

S. W. Seo, G. S. Jung, J. S. Lee, C. M. Bae, H. K. D. H. Bhadeshia and D. W. Suh

Abstract

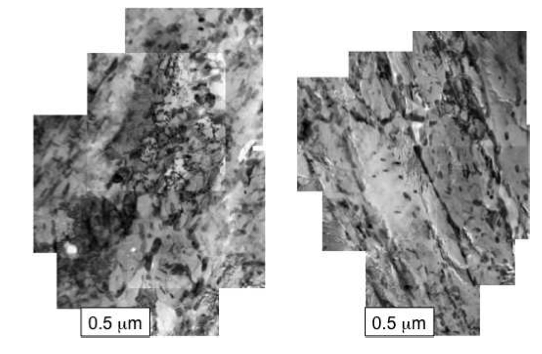

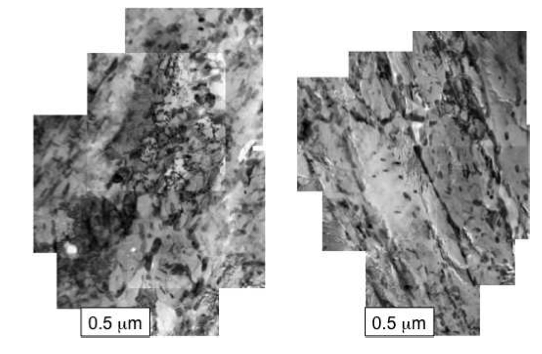

The prospect of enhancing the hardness of low-alloy steel for the manufacture of fasteners is examined using ausforming, in which the austenite is deformed rapidly at a low temperature to increase its dislocation density prior to quenching in order to obtain the harder martensite. Surprisingly small deformations accomplish large gains in hardness and the dislocation density of martensite, with diminishing returns at larger deformations. The main contribution to the hardness has been identified as the extra dislocations inherited by the martensite from the deformed austenite, rather than the refinement of microstructure by the ausforming process. Clear evidence is reported for the mechanical stabilisation of the austenite due to ausforming. Tempering heat-treatments tend to diminish the advantages of ausforming.

Materials Science and Technology 31 (2015) 436-442.

Download paper

Download data archive (0.3 Gb)

Related papers

- "Mechanical Stabilization of Bainite"

Materials Science and Technology, Vol. 11, 1995, 1116-1128.

P. Shipway and H. K. D. H. Bhadeshia

- "Quantitative Evidence for the Mechanical Stabilisation of Bainite"

Materials Science and Technology, Vol. 12, 1996, pp. 610-612.

S. B. Singh and H. K. D. H. Bhadeshia

- "The Mechanical Stabilisation of Wimanstatten Ferrite"

Materials Science and Engineering A, Vol. 223, 1997, pp. 179-185.

P. Shipway and H. K. D. H. Bhadeshia

- "Mechanical Stabilisation of Bainite"

Advances in Materials and Materials Processing

Proceedings of the International Conference, 1-4 February 2002, Kharagpur, India. Edited by U. Chaterjee and N. Chakraborti, published by Tata/McGraw-Hill, Dehli, (2002).

S. B. Singh and H. K. D. H. Bhadeshia

- "Mechanical Stabilisation of Austenite"

Materials Science and Technology, Vol. 22 (2006) 641-644.

S. Chatterjee, H.-S. Wang, J. R. Yang and H. K. D. H. Bhadeshia

- Mechanical Stabilisation of Eutectoid Steel"

Materials Science and Technology, Vol. 23, 2007, pp. 610-612.

M. Maalekian, E. Kozeschnik, S. Chatterjee and H. K. D. H. Bhadeshia

- "Mechanical Stabilisation of Retained Austenite in δ-TRIP Steel"

Materials Science and Engineering A 528 (2011) 5900-5903.

H. L. Yi, K. Y. Lee and H. K. D. H. Bhadeshia

- "Austenite stability and heterogeneous deformation in fine-grained TRIP-assisted steel"

Scripta Materialia 69 (2013) 933-936.

J. H. Ryu and J. I. Kim and H. S. Kim and C.-S. Oh and H. K. D. H. Bhadeshia and D. W. Suh