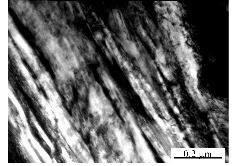

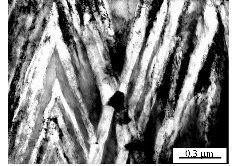

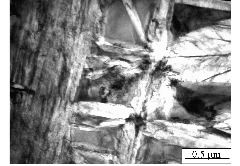

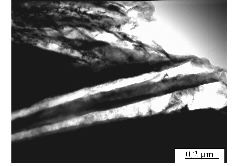

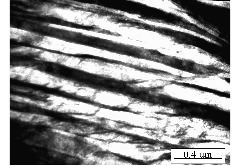

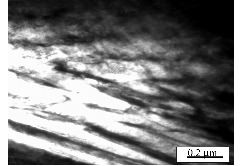

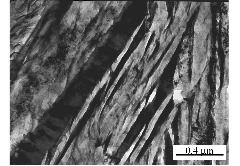

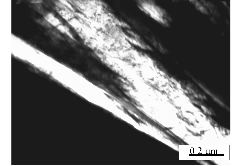

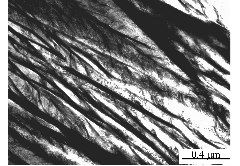

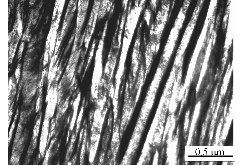

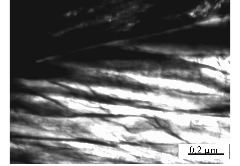

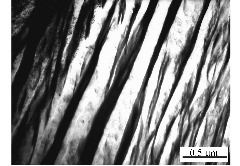

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 170°C for 18 days.

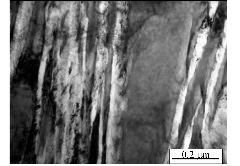

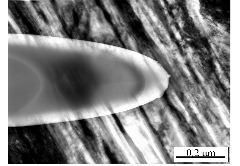

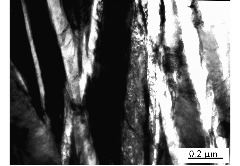

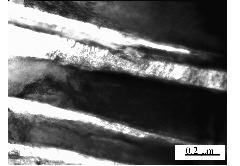

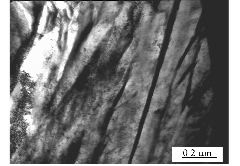

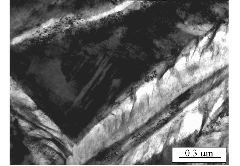

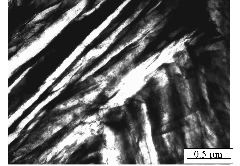

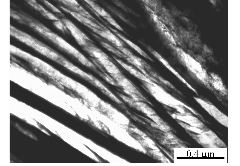

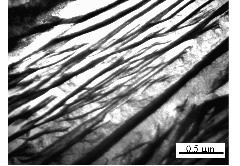

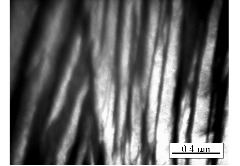

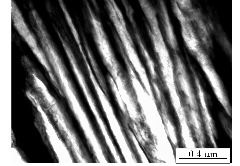

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days.

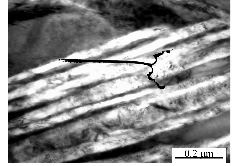

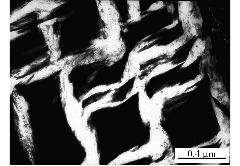

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 200°C for 3 days. Tensile tested.

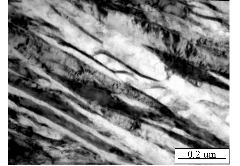

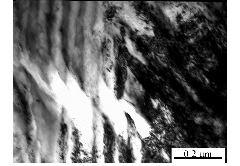

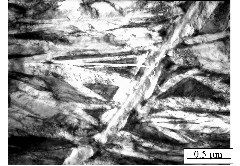

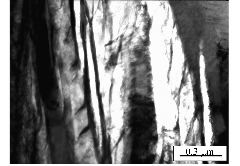

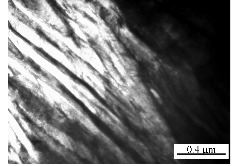

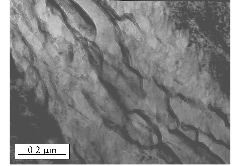

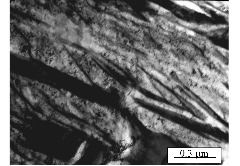

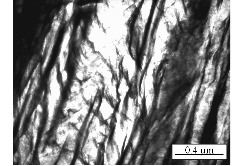

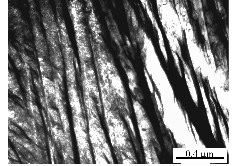

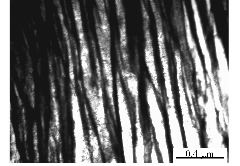

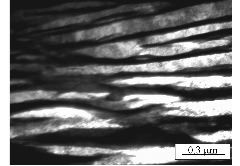

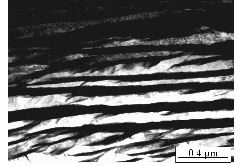

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 250°C for 10 h.

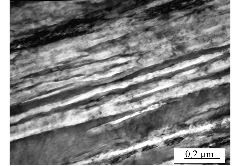

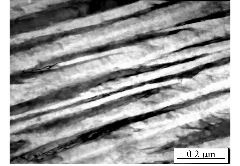

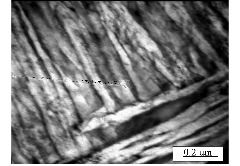

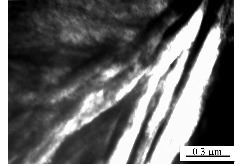

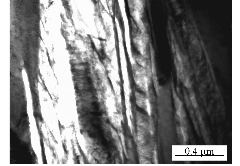

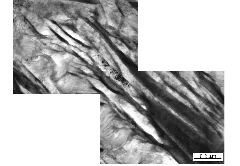

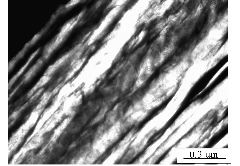

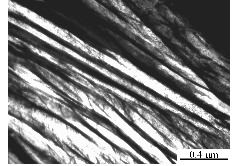

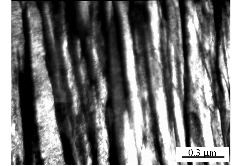

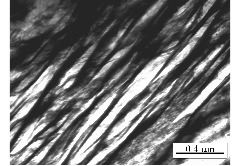

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.

Fe-0.79C-1.56Si-1.98Mn-0.24Mo-1.01Cr-1.51Co-1.01Al wt% Austenitised at 900°C for 30 min. isothermally transformed at 300°C for 8 h.