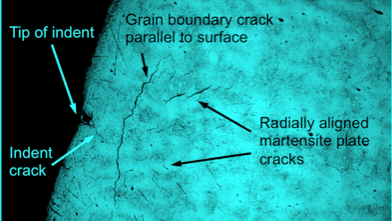

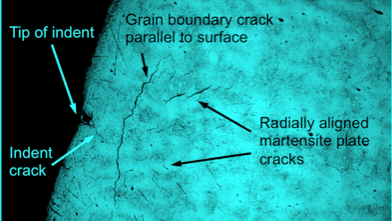

Although most of the research performed in steel metallurgy aims to prevent crack nucleation and propagation, some applications require the exact opposite in order to study the role that disconnected surfaces inside the bulk material play when load is applied, or when fluids entrapped in surface cracks propagate tensile stresses or exacerbate corrosion. Four heat treatments have been designed to create controlled arrays of crack types and distributions in a quenched and untempered steel normally used in the manufacture of bearings. The varieties of cracks studied include sparsely distributed martensite-plate cracks, fine grain boundary cracks, abundant martensite-plate cracks, and surface breaking cracks. The intention was to create samples which can then be subjected to appropriate mechanical testing so that phenomena such as the appearance of "white etching areas" or "white etching cracks", crack-lubricant interactions, or the role of defects on adiabatic shear band formation for ordnance applications can be studied further.

Metallurgical and Materials Transactions A 45 (2014) 4907-4915.

Download archive of crack images

Download archive of thermal etching images

| PT Group Home | Materials Algorithms |