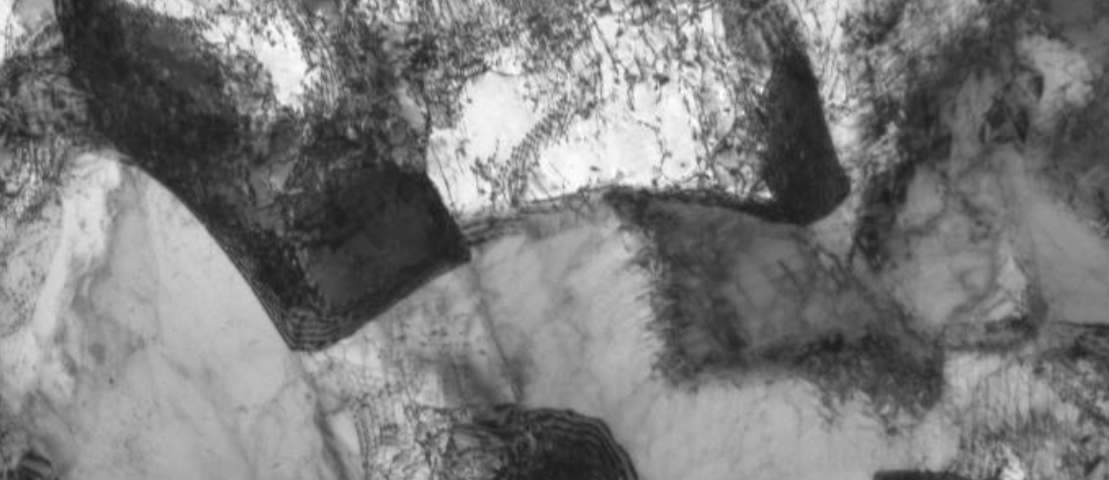

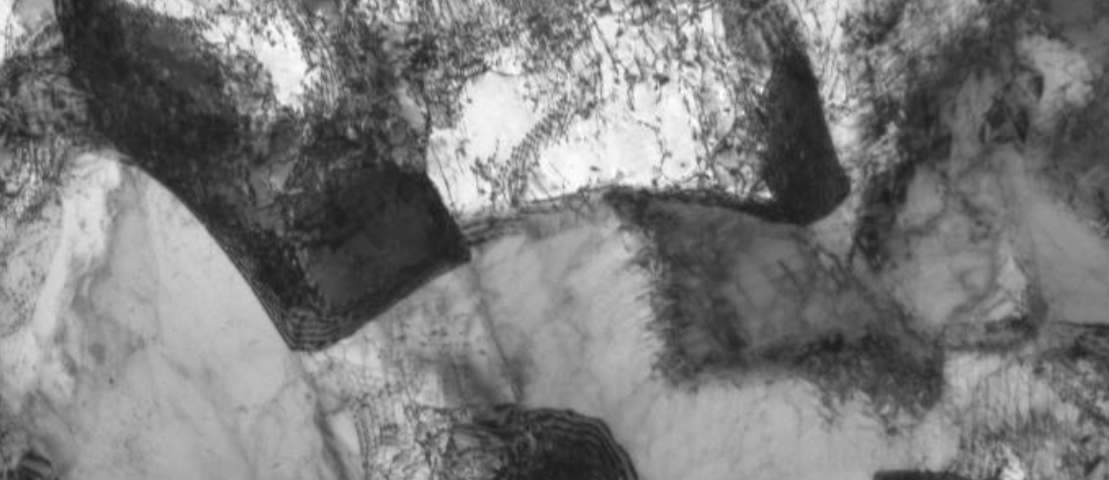

The surface of Fe-7Al (mass%) ferritic alloy plate was successfully modified by friction stir processing (FSP) with SiC particles. The stir zone with SiC addition had an average grain size of 4.3 μm, smaller than that of 7.0 μm in the stir zone without SiC addition. SiC particles introduced by FSP were broken into pieces by interaction with the rotating tool and were converted to Fe3AlCx particles by reaction with the ferrite matrix. The hardness near the surface of the stir zone was significantly increased to 270 HV by introduction of particles, compared to the hardness of 200 HV in the stir zone without particle additions.

Materials Science Forum 838-839 (2016) 326-331.

| PT Group Home | Materials Algorithms |