Type IV cracking refers to the premature failure of a welded joint due to an enhanced rate of creep void formation in the fine grained or intercritically annealed heat affected zone. A great deal of research effort has been directed at understanding the underlying mechanisms for this type of failure, but most have approached the problem from a metallurgical standpoint, and comparatively little effort has been directed at understanding the effects of welding variables. Here the effects of parameters such as the preheat temperature and heat input on the tendency for type IV failure in 9-12%Cr steels have been quantitatively estimated. These calculations have subsequently been verified experimentally to form the first systematic study of welding parameters on type IV cracking. The joint geometry and preheat temperature have been found to ameliorate type IV failures, while the effect of heat input is less significant.

Science and Technology of Welding and Joining 14 (2009) 436-442.

Review on Type IV cracking in steel welds.

Quantitative Estimation of Type IV cracking Tendency.

Welding procedures and Type IV cracking.

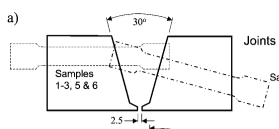

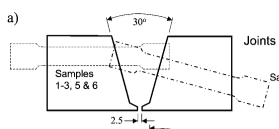

Experiments on Welding procedures and Type IV cracking.

Design of Alloys for The Energy Industries

Photographs of Australia, where this work was carried out.

Tempered martensite Fe-9Cr-1Mo weld metal.

| Performance | Foam | TWIP | FSW | FSW, steel |

| Anisotropy | Properties | Texture | Cementite | Models |

| Neural Networks | Creep | Mechanicallly Alloyed | Topology | Microalloying |

| PT Group Home | Materials Algorithms |